Full-automatic fixed distance drilling device for cylindrical pins and method

A cylindrical pin, fully automatic technology, applied in positioning devices, clamping devices, feeding devices, etc., can solve the problems of complex structure, area consumption, difficult maintenance, etc., to improve processing efficiency, simplify device structure, and simplify positioning steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

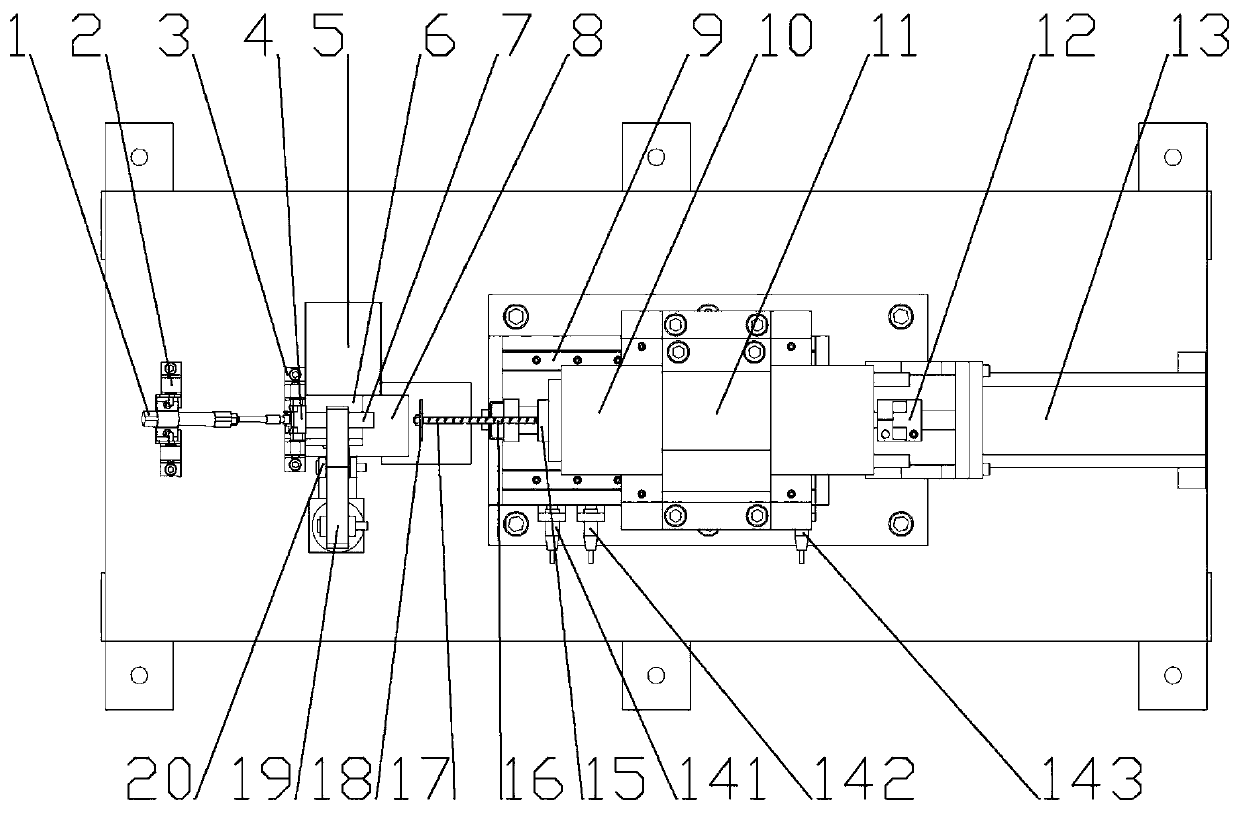

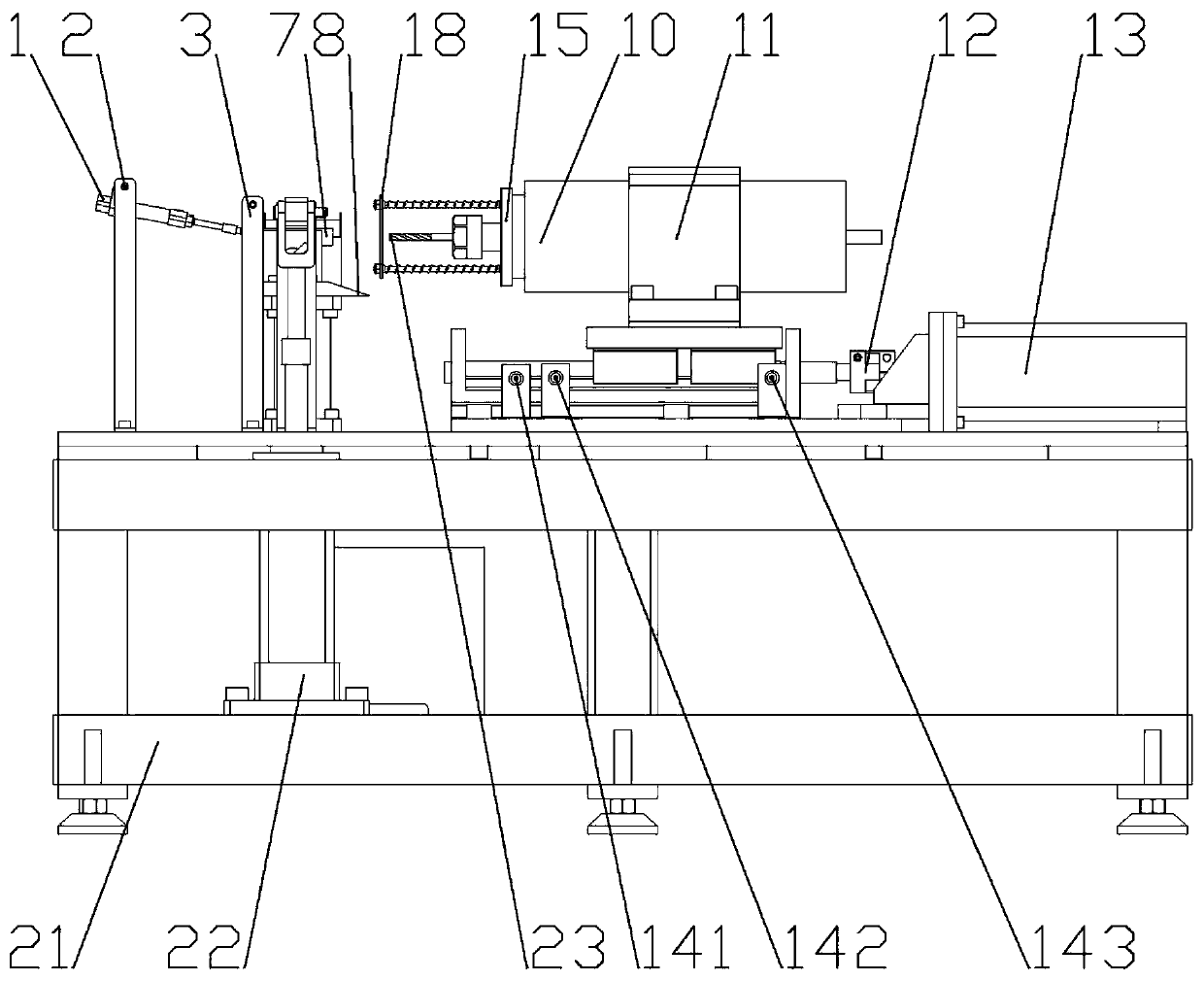

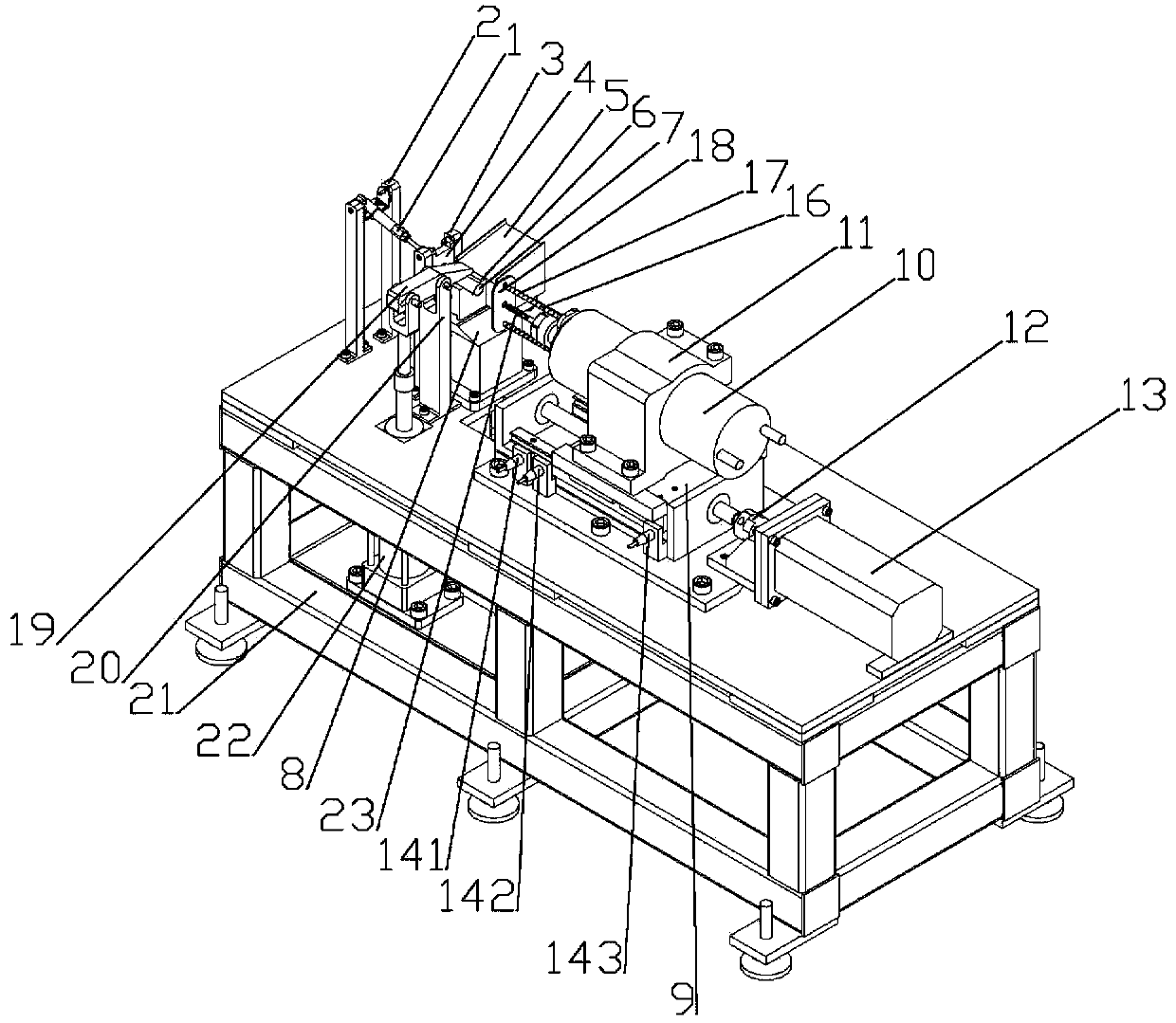

[0030] see Figure 1-3 , a full-automatic cylindrical pin fixed-range drilling device, which includes a frame 21, a V-shaped block 6 is fixedly installed on the top middle part of the frame 21, and a V-shaped block 6 is installed on one axial end of the V-shaped block 6 for The positioning and unloading device for positioning and unloading the cylindrical pin to be processed is equipped with a drilling positioning device for drilling and auxiliary positioning at the other end of the axial direction. The radial ends of the V-shaped block 6 are respectively installed with useful The feeding chute 5 for feeding and the clamping device for compressing the cylindrical pin to be processed. The drilling device adopting the above-mentioned structure can be used for the automatic drilling operation of the cylindrical pin, which can realize the automatic loading of the cylindrical pin 7 to be processed, and can realize its automatic positioning and clamping after loading, and after posi...

Embodiment 2

[0039] The method for processing cylindrical pins with a fixed-range drilling device for fully automatic cylindrical pins is characterized in that it comprises the following steps:

[0040] Step 1: Roll the cylindrical pin 7 to be processed to the V-shaped block 6 along the feeding slide 5;

[0041]Step 2: The positioning cylinder 1 pushes the positioning door panel 4 to close, and the driving motor 13 drives the screw nut slide table 9 to make the electric spindle 10 and the spring push plate 18 approach the cylindrical pin 7 to be processed until the spring push plate 18 pushes the cylindrical pin 7 to be processed Make its other end contact the positioning door panel 4;

[0042] Step 3: When the screw nut slide table 9 reaches the second proximity switch 142, the slide table stops moving forward, and the clamping cylinder 22 uses the lever principle to push the weight 19 to clamp the cylindrical pin 7 to be processed;

[0043] Step 4: Slide table 9 advances again, drives k...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com