A molding method, molding equipment and printed matter of a structure with a dynamic three-dimensional effect

A technology of three-dimensional effect and molding method, which is applied in the direction of printing, printing, and printing machines for the production of special varieties of printed matter. It can solve problems such as difficult degradation, increased manufacturing costs, and unfavorable environmental protection, and achieve good packaging effects. Simplify processing technology and improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

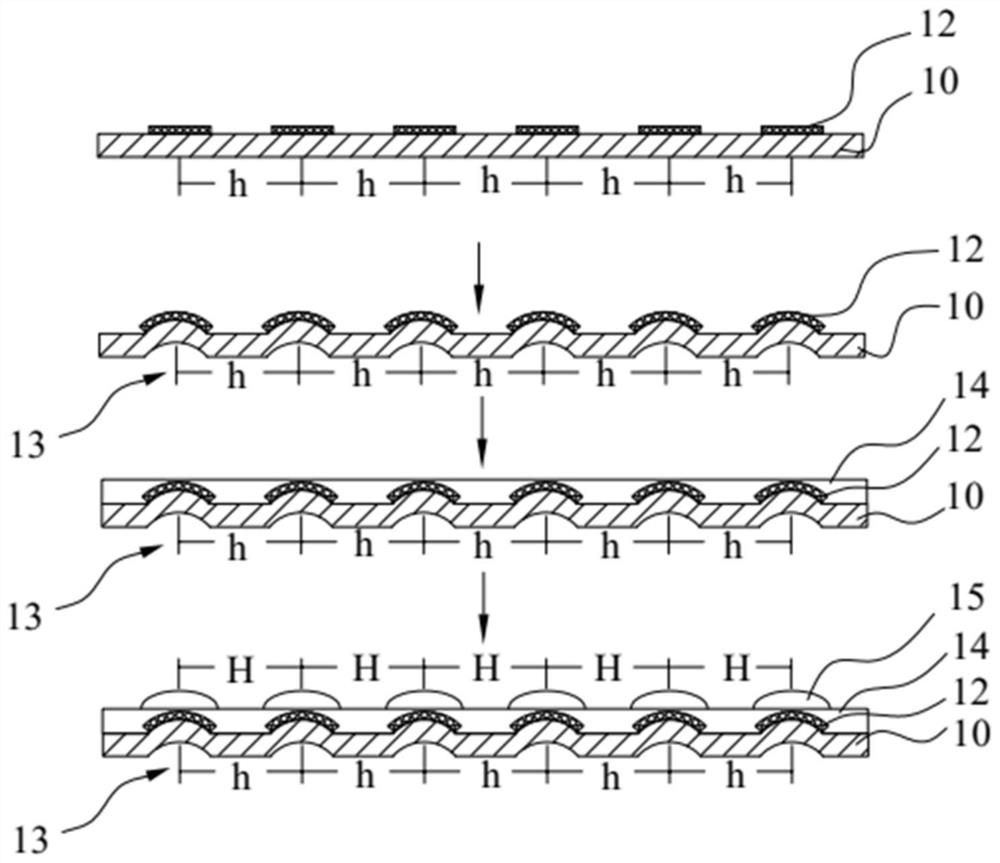

[0054] To solve the above problems, such as figure 1 As shown, this embodiment discloses a method for forming a structure with a dynamic three-dimensional effect, which specifically includes: printing a plurality of graphics and texts 12 with a three-dimensional effect on the surface of the paper base material 10, and after the graphics and texts 12 are dried, Roll the paper base material 10 so that each area printed with graphics and text 12 forms an arc-shaped protrusion 13; the surface of the paper base material 10 printed with graphics and text 12 is coated with a transparent first resin oil layer 14; After the first resin oil layer 14 is dried, a dot-shaped transparent second resin oil layer is coated on the surface of the first resin oil layer 14. The second resin oil layer shrinks naturally and is cured by ultraviolet radiation to form a plurality of lens structures 15, adjacent to each other. The distance between the lens structures 15 is larger or smaller than the dis...

Embodiment 2

[0065] Figure 4 It is a process schematic diagram of the forming method of the structure with dynamic three-dimensional effect provided by the second embodiment of the present invention. Such as Figure 4 As shown, the method for forming a structure with a dynamic three-dimensional effect disclosed in this embodiment specifically includes: coating and forming a water-oil layer 11 on the surface of the paper-based material 10; A plurality of graphics and texts 12 with three-dimensional effects are printed; after the above graphics and texts 12 are dried, the paper base material 10 is rolled so that each area printed with graphics and texts 12 forms an arc-shaped protrusion 13; on the paper base material 10 The surface coated with graphics and texts 12 is coated with a transparent first resin oil layer 14; after the first resin oil layer 14 is dried, a dot-shaped transparent second resin oil layer is coated on the first resin oil layer 14, and the second resin oil layer is nat...

Embodiment 3

[0069] Figure 5 It is a process schematic diagram of the forming method of the structure with dynamic three-dimensional effect provided by the third embodiment of the present invention. Such as Figure 5 As shown, in this embodiment, silver cardboard is used as the paper base material 10, and the forming method of the structure having a dynamic three-dimensional effect is the same as that of the first embodiment.

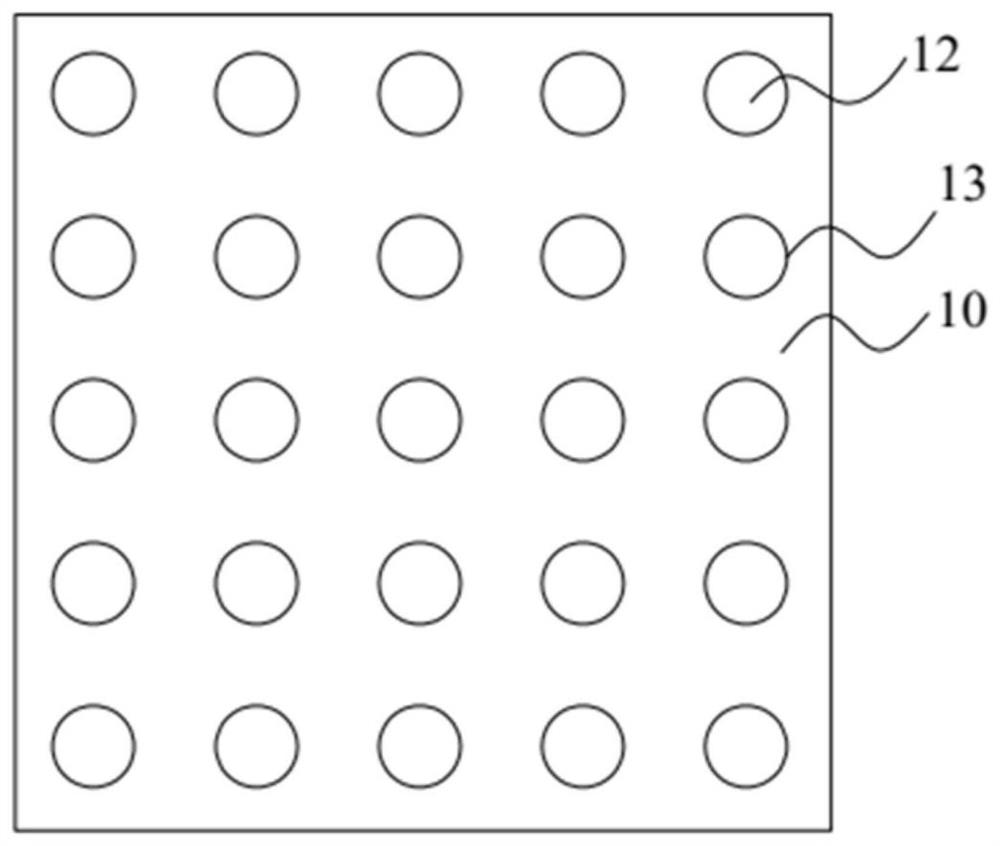

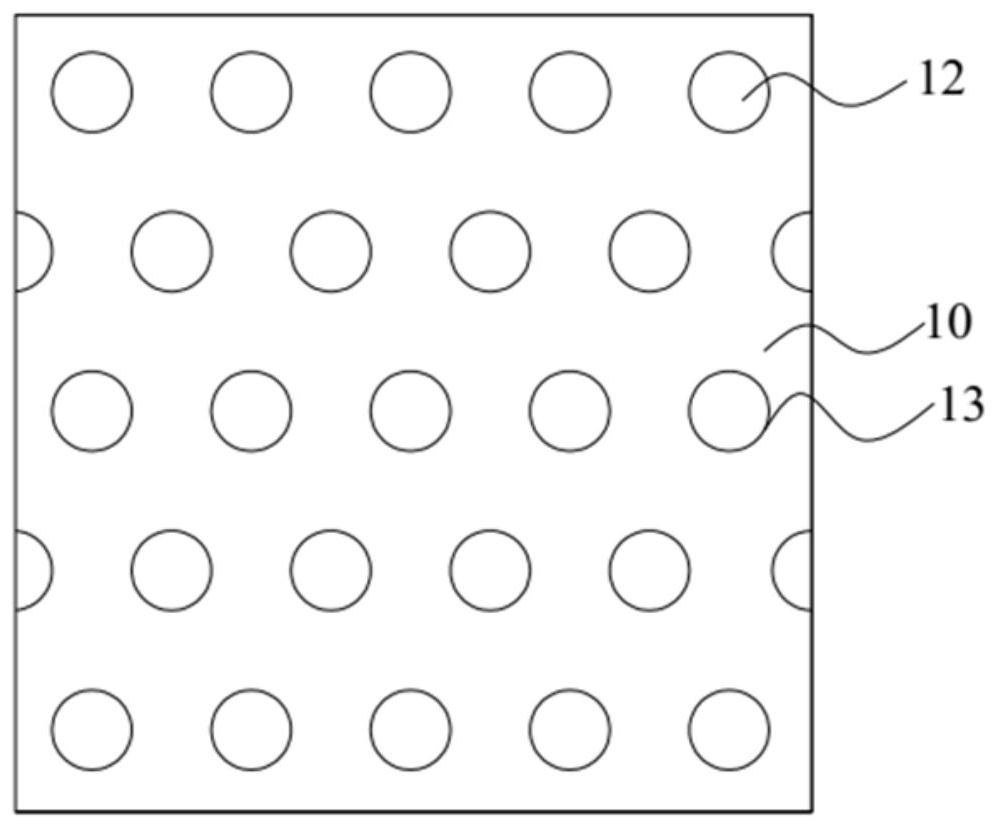

[0070] In the present embodiment, it is also taken as an example to enlarge and float images formed by three-dimensional effect pictures and texts 12, wherein each picture and text 12 is a circular pattern and the diameter of the circular pattern is 0.03mm, and the arrangement pitch of the circular patterns is 0.2 mm, the diameter of the arc-shaped protrusion 13 is 0.12 mm, and the height of the arc-shaped protrusion 13 is 0.15 mm. In order to clearly see the final dot-shaped image with a three-dimensional effect, the arrangement pitch of the circular pattern is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com