Adaptive pipe dredging robot

A robotic and self-adaptive technology, applied in special pipes, pipe components, telephone communications, etc., can solve problems such as inability to adapt to changes in pipe diameter, inability to change, inconvenience in life, etc., to achieve strong commercial promotion value, reduce investment, and utilization rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

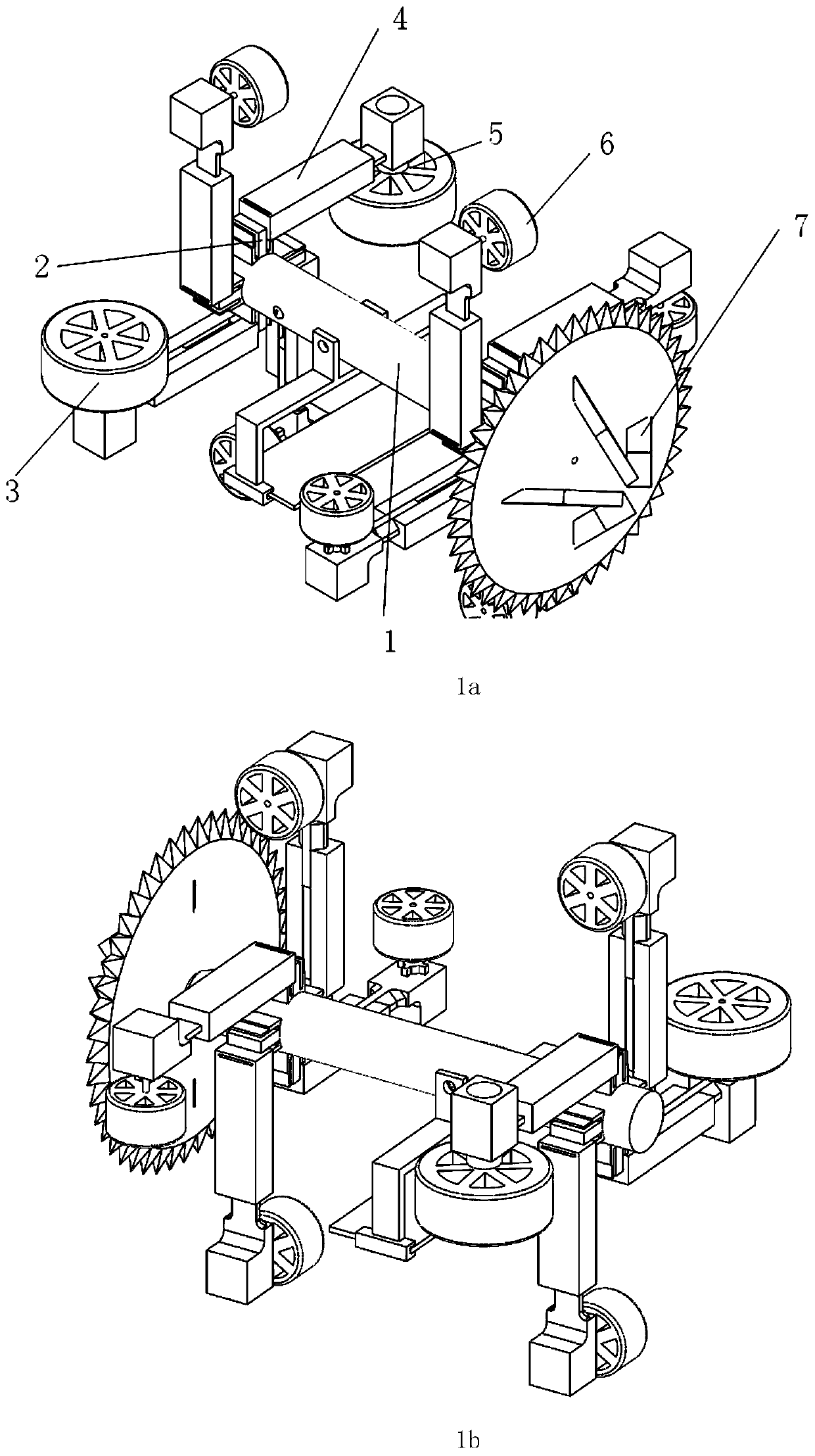

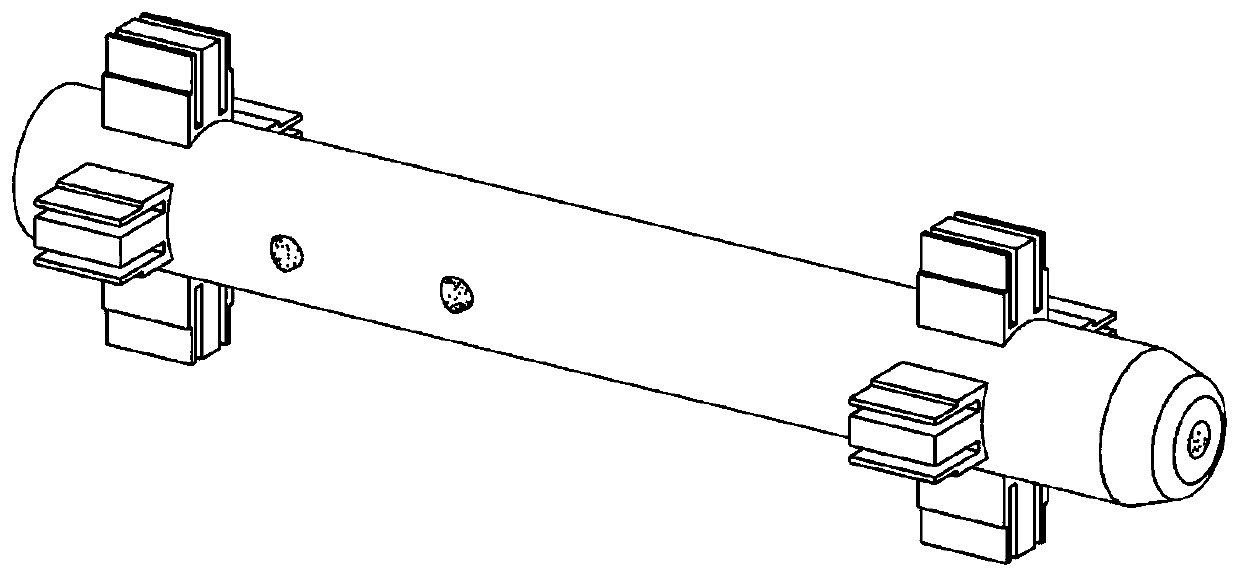

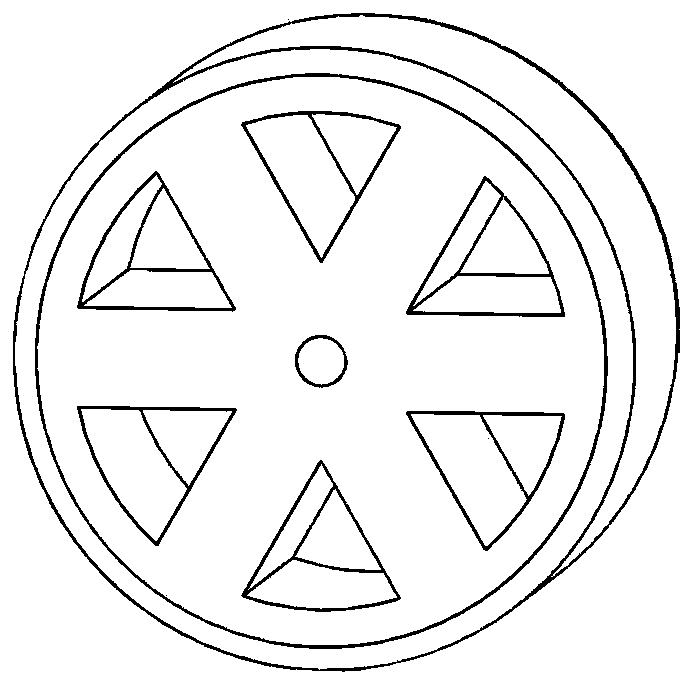

[0032] Such as figure 1 As shown in a, 1b, and 2, an adaptive pipeline dredging robot includes a main shaft 1, and the two ends of the main shaft are integrally connected with a main shaft connector 2, and each end has four main shaft connectors, and the four main shaft connectors are in the shape of a cross Connected on the main shaft, each main shaft connector has a pivot joint for pivoting the guide rail 4; the front end surface of the main shaft is provided with a mounting hole for connecting the rotary drill 7, and the rotary drill is rotatably connected to the front end surface, and the rotary drill The drive motor is connected to the top, and a guide rail is pivotally connected to the four main shaft connectors near the front end, and a driven wheel 6 is rotatably connected to each guide rail. When the robot is located in the pipeline, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com