Air treatment equipment for coating production

A technology of air treatment and coating, which is applied in the direction of gas treatment, combined device, membrane technology, etc., and can solve problems such as the impact of equipment operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

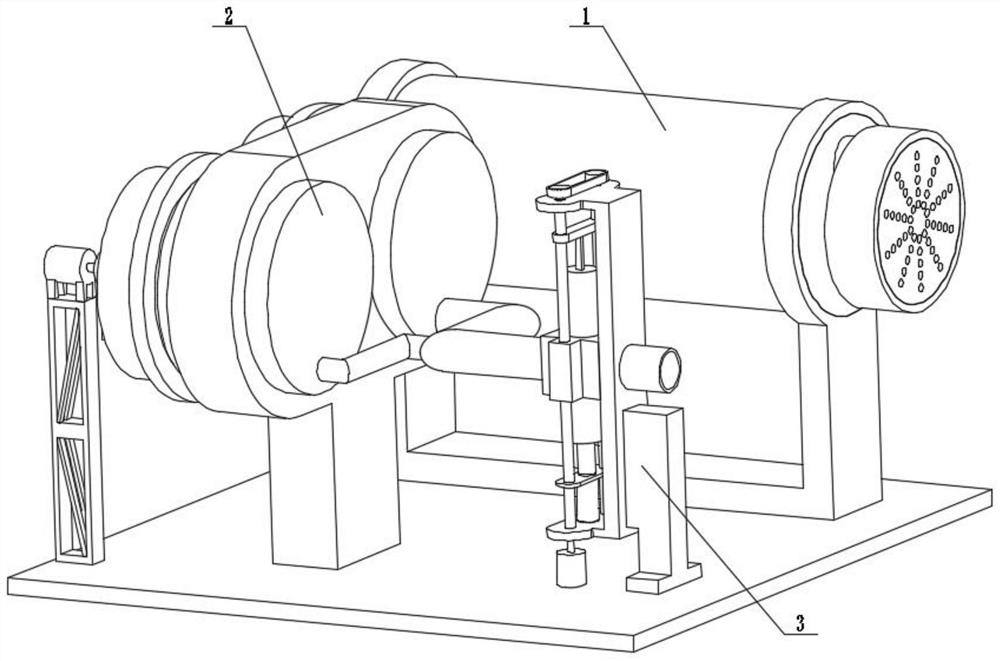

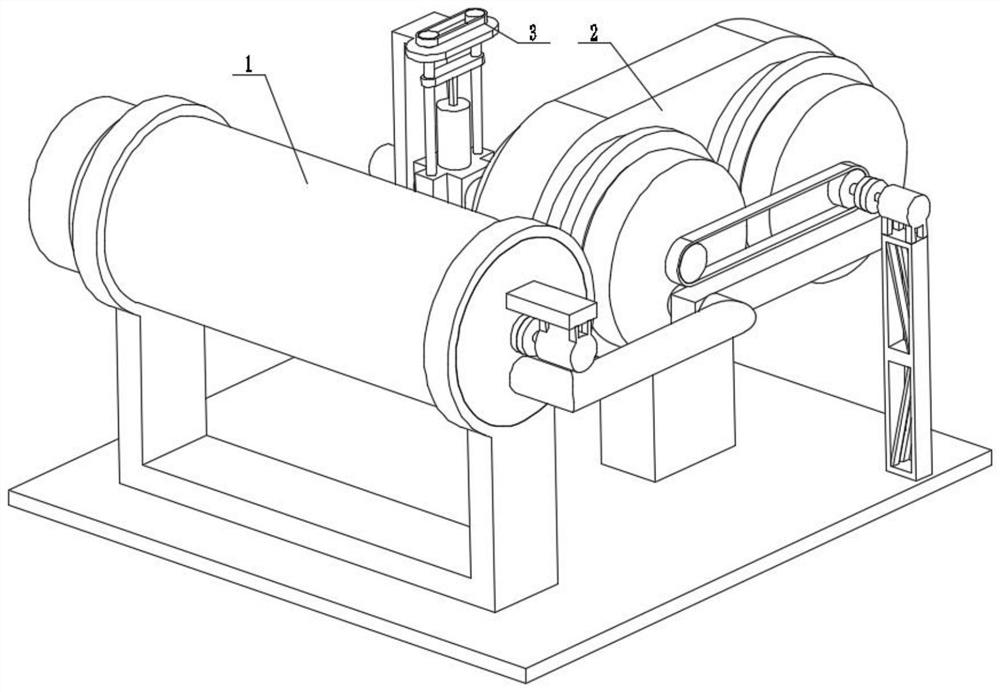

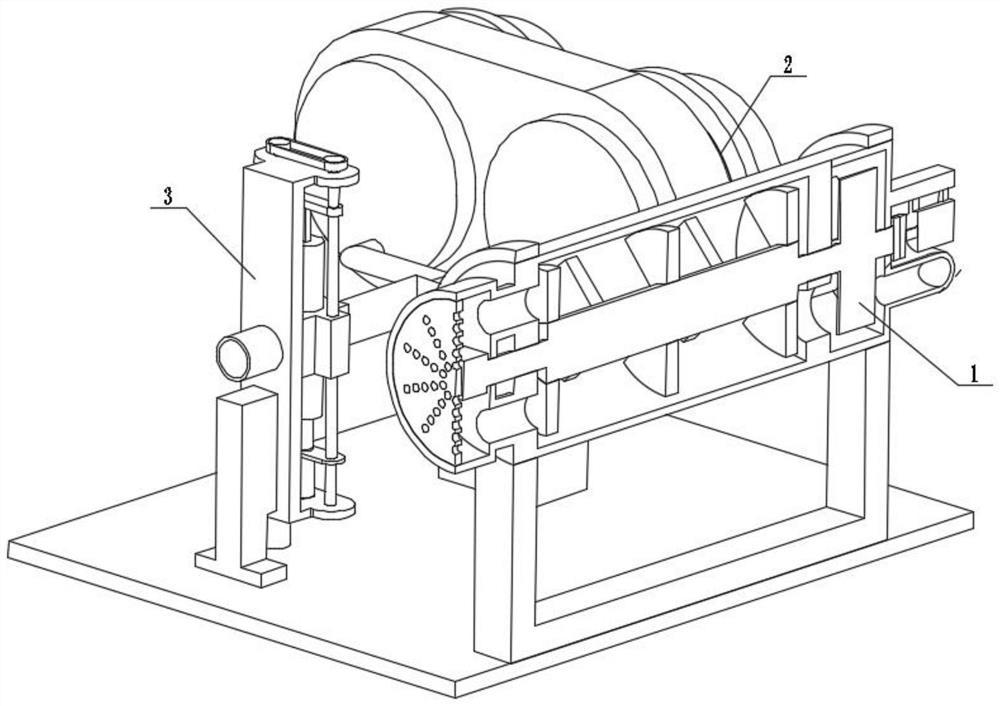

[0030] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 Describe this embodiment. The present invention relates to an air treatment equipment, more specifically, an air treatment equipment for paint production, including a paint molecule removal mechanism 1, an adsorption mechanism 2, and an adjustment and cleaning mechanism 3. The equipment can filter and remove floating paint. Molecules, the equipment can fully absorb the gas, the equipment can cool the gas to a certain extent, the equipment can maintain the speed of the wind, and the equipment can clear the blockage.

[0031] The paint molecule removal mechanism 1 is connected with the adsorption mechanism 2, and the adsorption mechanism 2 is connected with the adjustment and cleaning mechanism 3.

specific Embodiment approach 2

[0033] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 Describe this embodiment, this embodiment will further explain the first embodiment, the paint molecule removal mechanism 1 includes a filter plate 1-1, an air inlet box 1-2, a connecting pipe 1-3, an auxiliary support 1-4, and a blower 1-5, air outlet box 1-6, air outlet box I1-7, coupling 1-8, motor 1-9, connecting pipe 1-10, air outlet pipe 1-11, splitter box 1-12, air outlet pipe 1-13, rotating shaft with seat 1-14, molecular grid block 1-15, wind wheel 1-16, partition plate with connecting port 1-17, cleaning seat 1-18, sliding chamber 1-19, spring 1-20 , the sliding seat 1-21, the filter plate 1-1 is connected with the air inlet box 1-2, the air inlet box 1-2 is connected and communicated with the connecting pipe 1-3, and the connecting pipe 1-3 is connected...

specific Embodiment approach 3

[0035] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 , Figure 14 , Figure 15 Describe this embodiment, this embodiment will further explain Embodiment 1. The adsorption mechanism 2 includes a motor steel frame support base 2-1, a motor I2-2, a coupling I2-3, and a rotating wheel with a compartment 2- 4. Outer ring gear 2-5, auxiliary support seat 2-6, outer ring gear I2-7, outer box 2-8, air outlet pipe 2-9, cleaning compression pipe 2-10, threaded hole seat for collecting air outlet Pipe 2-11, pressure relief pipe 2-12, base 2-13, secondary air outlet pipe 2-14, outer box I2-15, belt shaft pulley 2-16, belt 2-17, rotating wheel with compartment I2-18, belt shaft pulley I2-19, arc protrusion 2-20, belt seat pulley 2-21, connecting column 2-22, spring 2-23, communication channel 2-24, connection port 2-25, sliding Seat I2-26, opening 2-27,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com