Saturated or supersaturated flue gas moisture content measuring and calibrating device

A technology of flue gas moisture content and calibration device, which is applied in measurement devices, analysis gas mixtures, instruments, etc., can solve the problem of inability to achieve accurate calibration of saturated or supersaturated flue gas moisture content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

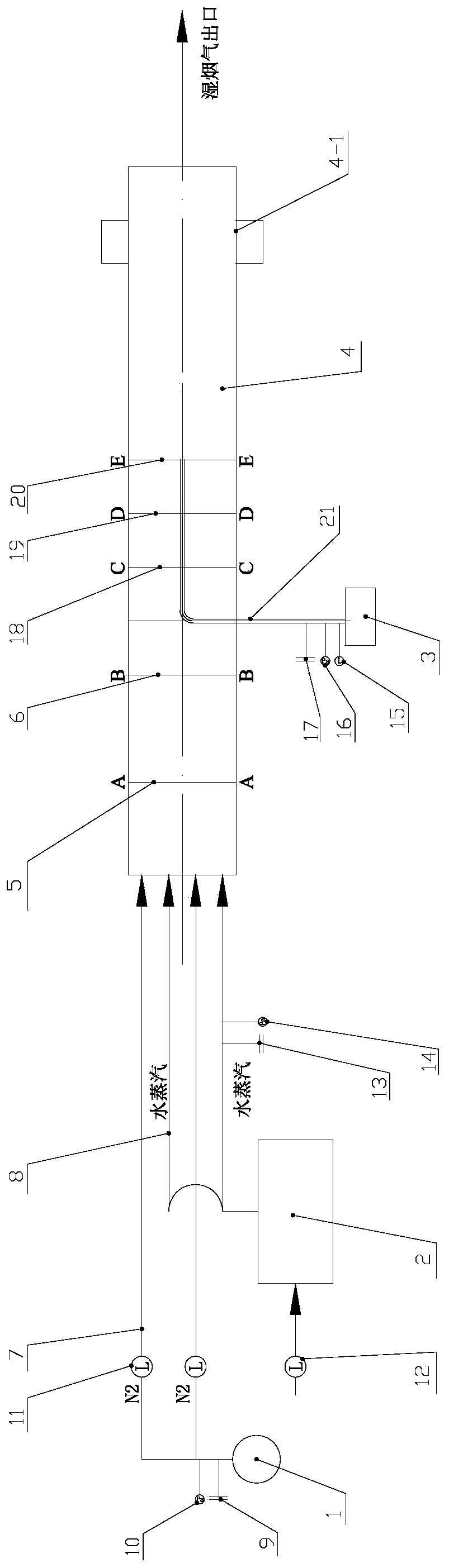

[0027] Specific implementation mode one: combine Figure 1~6 Describe this embodiment, a saturated or supersaturated flue gas moisture content measurement and calibration device, which includes a single gas electric heating device 1, an electric hot water steam generator 2, an electric water heater 3 and an adiabatic flue 4,

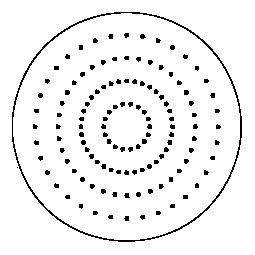

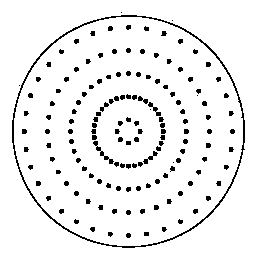

[0028] The adiabatic flue 4 is a cylindrical structure arranged horizontally, the openings at both ends are the inlet end and the outlet end respectively, and the first gas spoiler is coaxially installed inside the adiabatic flue 4 from the inlet end to the outlet end in sequence 5. The second gas spoiler 6 and the droplet generator, at least one detection hole 4-1 is provided on the adiabatic flue 4 near the outlet end,

[0029] The single gas electric heating device 1 transports the heated single gas to the inlet end of the adiabatic flue 4 through at least two single gas pipelines 7, and the electric hot water steam generator 2 transmits the heated si...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com