Casting surface defect identification method based on deep convolutional neural network

A convolutional neural network and defect identification technology, applied in the field of casting surface defect detection, can solve problems such as inaccurate positioning, easy misjudgment and missed judgment, and inability to accurately predict size, achieving high calculation efficiency, strong classification ability, and improved The effect of target discrimination ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044]The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

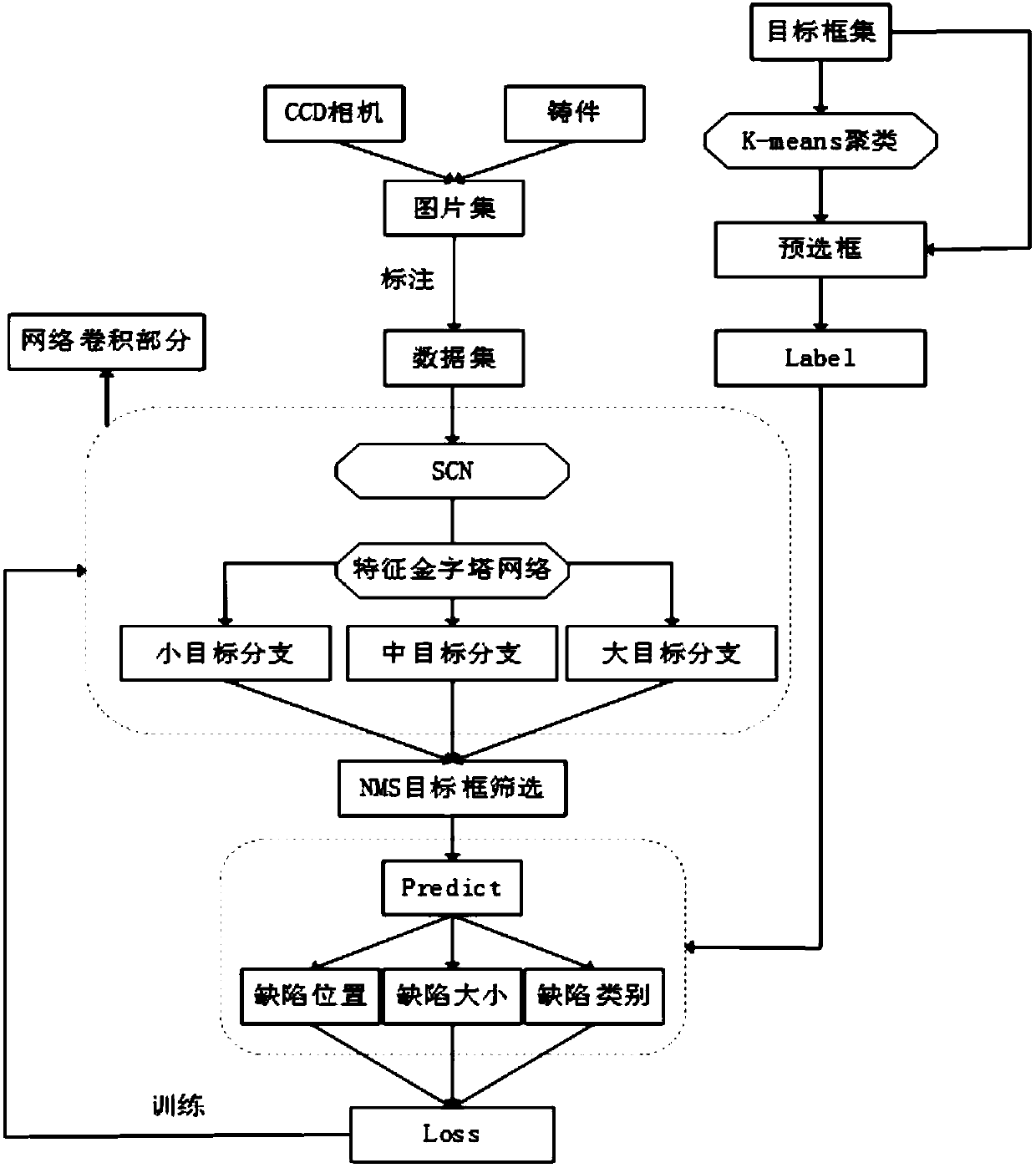

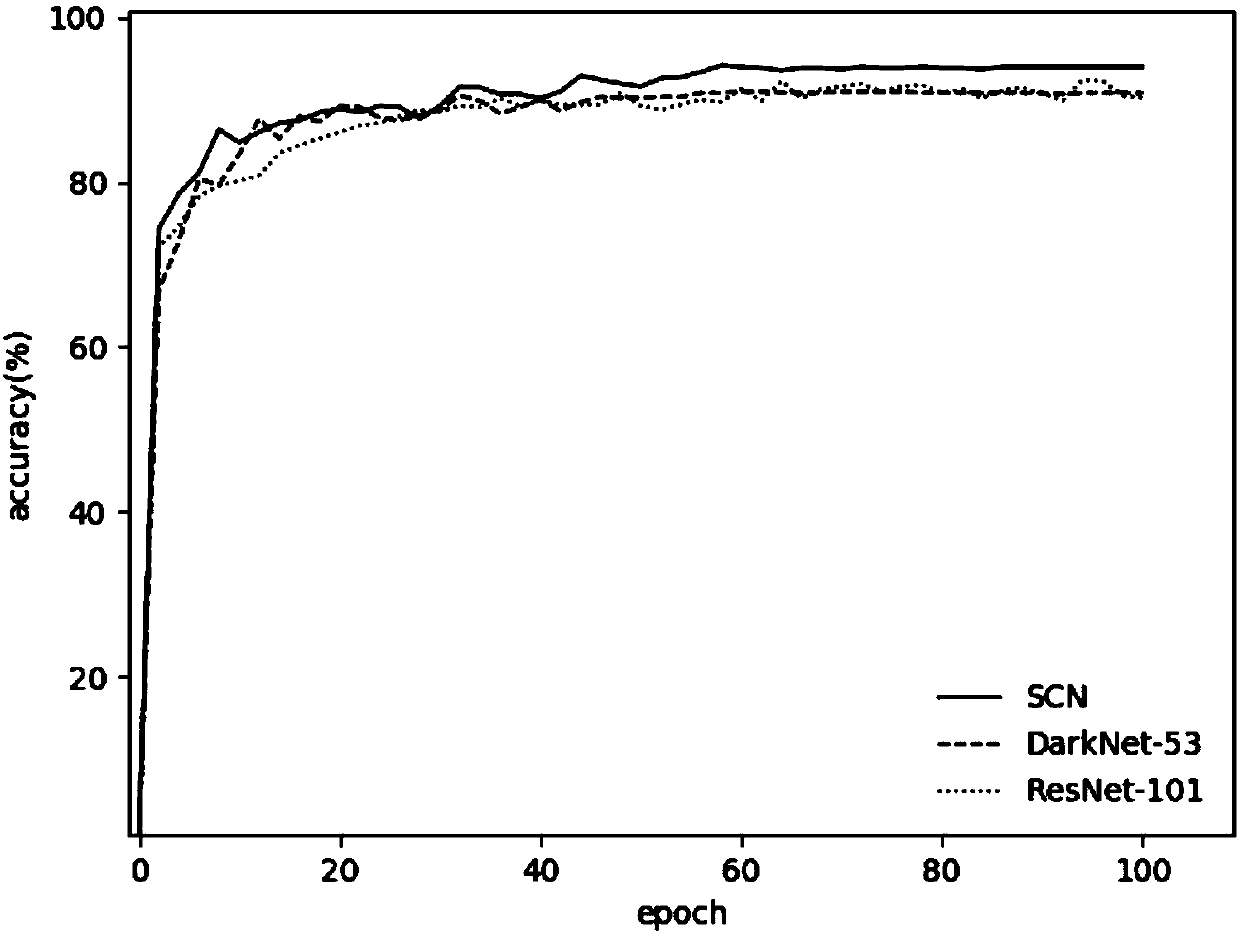

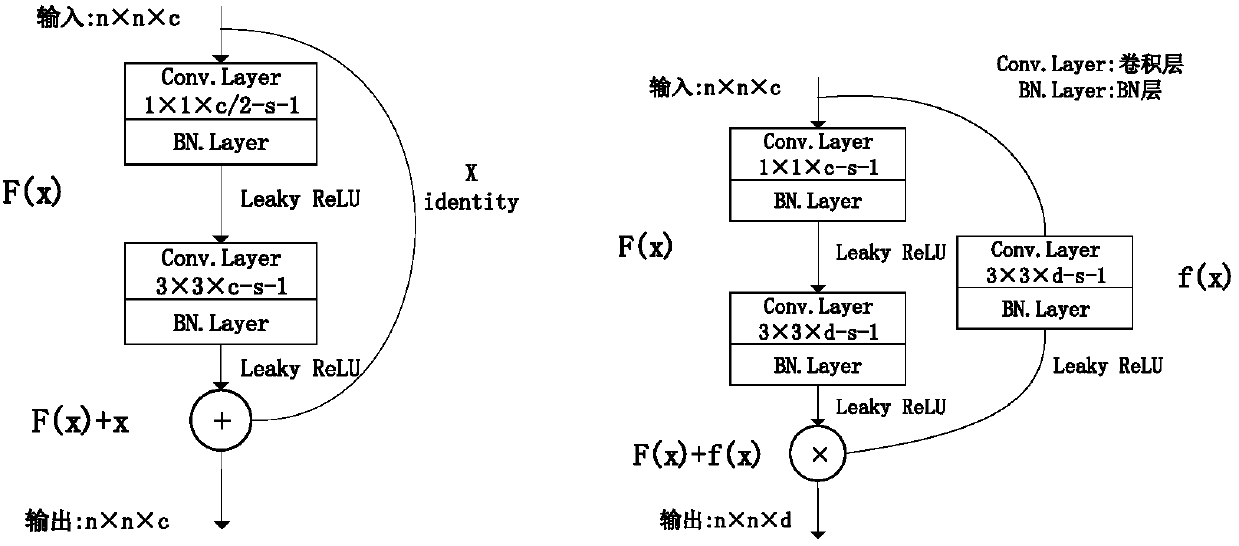

[0045] The invention proposes a casting surface defect recognition method based on a deep convolutional neural network, which can detect casting surface defects intelligently and online in real time. This method first uses the designed SCN with a symmetric module to extract features from the input image, then uses three prediction branches similar to the feature pyramid network to make predictions on three scales based on the features extracted by the backbone network, and finally passes the non-maximum value The suppression algorithm (NMS) screens the target boxes.

[0046] The flow chart of the casting surface defect recognition method based on deep convolutional neu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com