Cover plate coloring method, cover plate and electronic equipment

A cover plate and cover bottom technology, applied in the direction of electrolytic inorganic material coating, chassis/cabinet/drawer parts, etc., can solve the problems of inability to make fine patterns, pure black or white, poor gradient effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

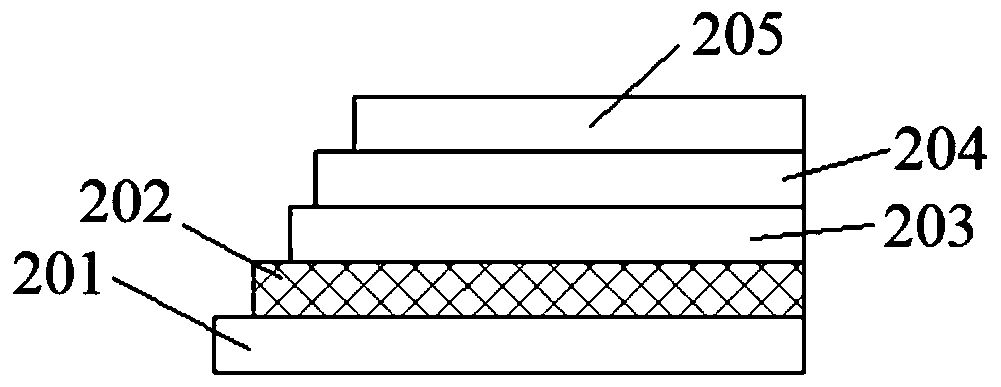

[0027] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0028] The present invention aims at the existing color scheme of the front screen cover of the mobile phone, which is mainly pure black or white, and adopts the silk screen printing process. Due to the limitations of the process, it is impossible to make fine patterns, and the gradient effect is poor. , there are obvious screen printing particles, and the appearance effect is poor. A method for coloring a cover plate, a cover plate and electronic equipment are provided.

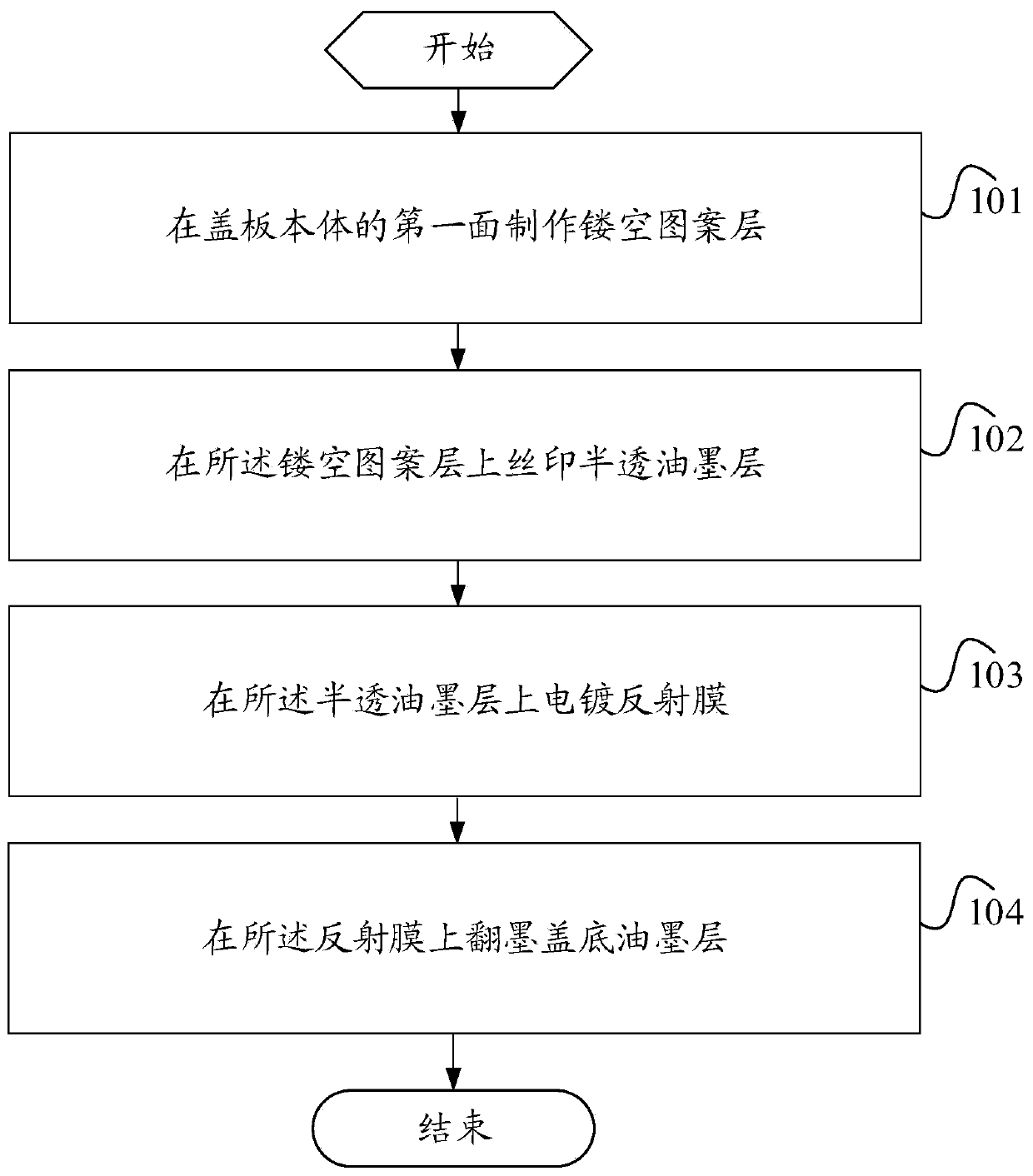

[0029] Such as figure 1 As shown, the embodiment of the present invention provides a cover coloring method, including:

[0030] Step 101, making a hollow pattern layer on the first surface of the cover plate body;

[0031] It should be noted that, the first surface of the cover ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com