Special gas-liquid buffer separation tank for vertical filter press

A vertical filter press and gas-liquid buffer technology, applied in the field of filter presses, can solve the problems of air containing impurities, high pressure of the filter press, inability to separate gas and water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

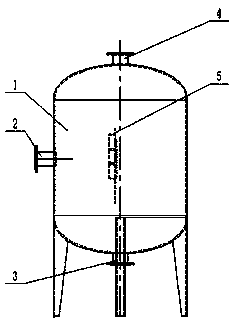

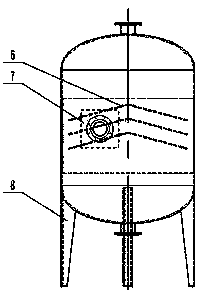

[0023] A special gas-liquid buffer separation tank for a vertical filter press, comprising a tank body 1 and a support plate 8, the top and bottom of the tank body 1 are welded with finished heads, and the support plate 8 is arranged on the outside of the tank body 1 Bottom, the top of the tank 1 is provided with an air outlet 4, this design facilitates the exhaust of the tank 1, the middle of one side of the tank 1 is provided with an air inlet 2, and the bottom of the tank 1 is provided with Drain port 3, this design is convenient for filtrate to drain away, and can also play the effect of sewage discharge. The middle position inside the tank body 1 is provided with a baffle 5, and the baffle 5 is arranged in parallel with the air inlet 2, The side of the baffle 5 facing the air inlet is provided with a plurality of baffles 6, which can increase the residence time of the gas in the tank as much as possible to improve the separation effect of steam and water, and the other sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com