Preparation method of personalized titanium mesh for bone defect reconstruction in tooth implantation area

A dental implant and titanium mesh technology, which is applied in dentistry, applications, and dental implants, can solve the problems of anatomical incompatibility, titanium mesh exposure, titanium mesh costly, etc., and achieve the effect of shortening operation time and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

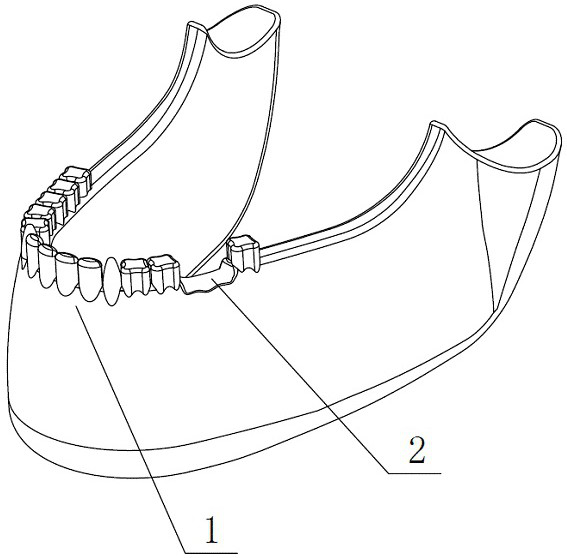

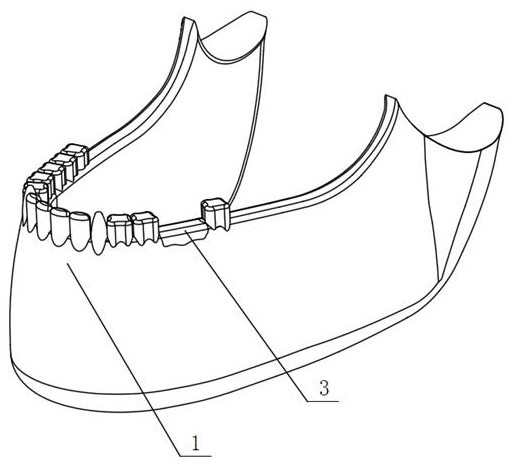

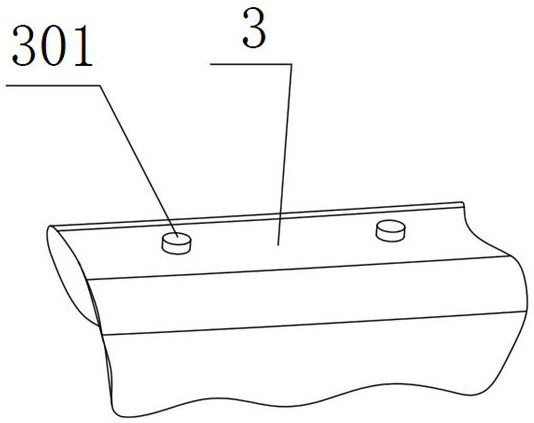

[0036] The following is combined with specific implementation and attached Figure 1-6 , to further illustrate the present invention.

[0037]The present invention is used for the preparation method of the personalized curved titanium mesh of bone reconstruction before planting, and it comprises the following steps:

[0038] A method for preparing a personalized titanium mesh for bone defect reconstruction in an implanted area, characterized in that it comprises the following steps:

[0039] The first step: extract the CBCT (cone beam CT) image of the patient's maxillofacial region, and perform 3D reconstruction to obtain a 3D digital model of the jaw;

[0040] Step 2: Place a digital implant model in the alveolar bone defect area 2 of the 3D digital model of the jaw, establish the alveolar bone defect model 3, and repair the alveolar bone defect area 2 in the 3D digital model of the jaw, and the alveolar bone defect Model 3 requires buccal-lingual to cover the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com