Composite artificial board with anticorrosion performance, mould proof performance and high fire resistance and manufacturing method of composite artificial board

A technology of anti-corrosion and anti-mildew, manufacturing method, applied in the direction of manufacturing tools, wooden veneer joints, wood processing appliances, etc., can solve problems that threaten life and property safety, prevent flame spread and spread, improve appearance quality and Physical properties, the effect of not easy to mildew and corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

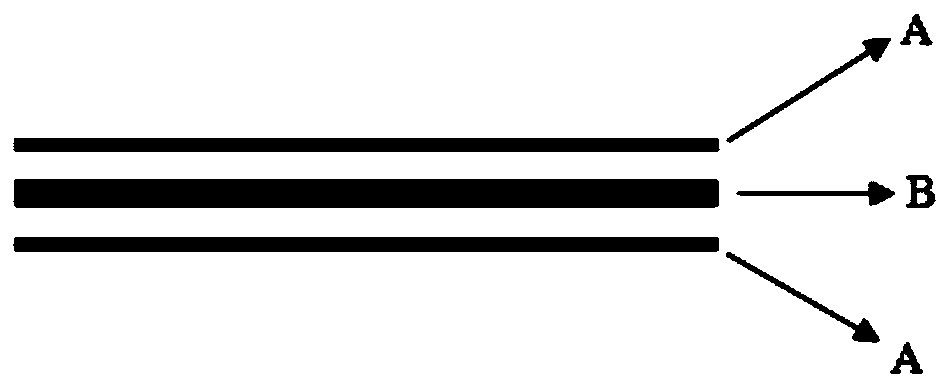

Image

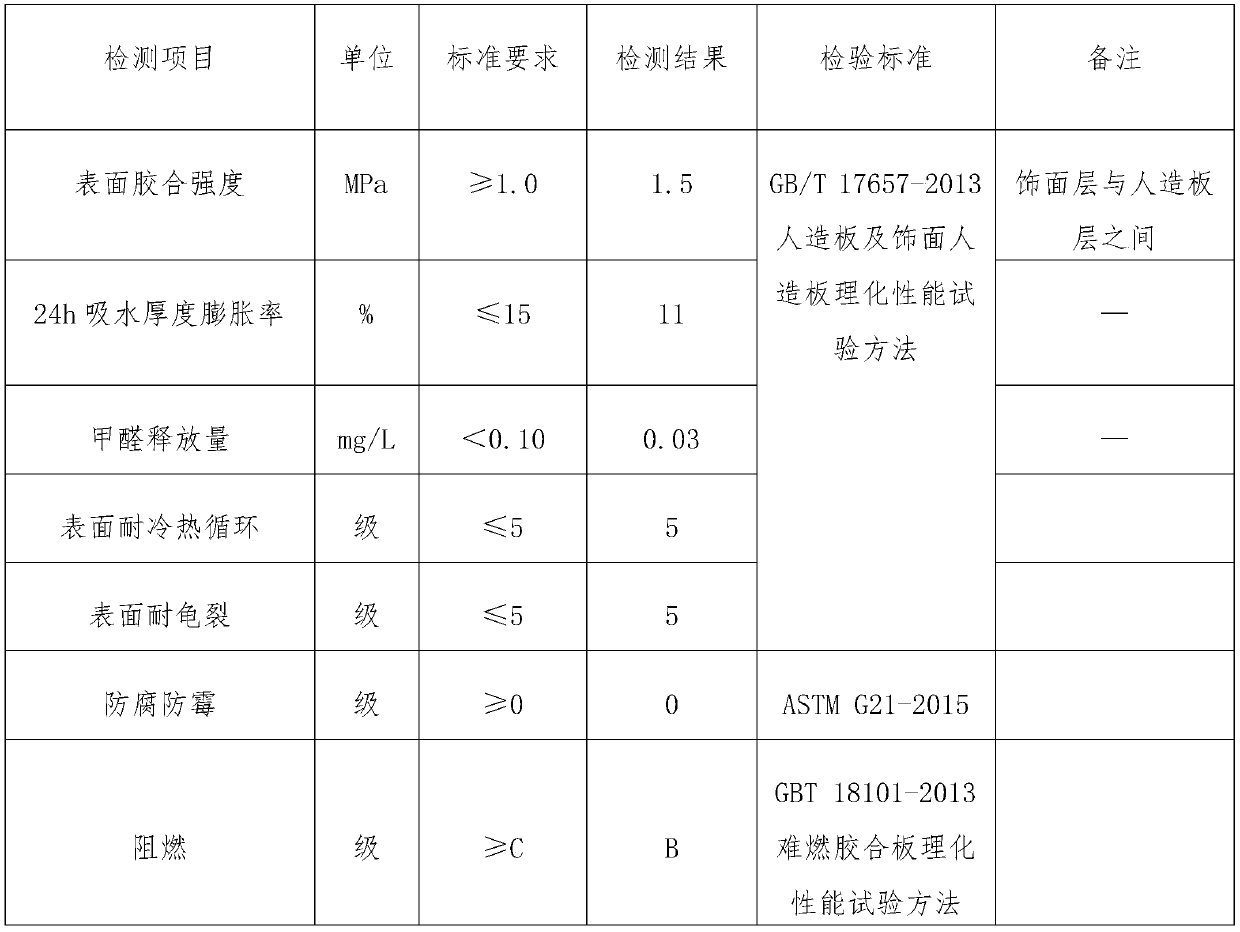

Examples

Embodiment 1

[0019] A method for manufacturing a composite wood-based panel with anti-corrosion, anti-mildew and high flame retardancy, comprising the following steps:

[0020] (1) The facing layer is glued with polyurethane adhesive, formaldehyde-free biomass adhesive or trialdehyde glue (urea formaldehyde, phenolic formaldehyde, melamine formaldehyde) and water repellant, antifungal agent, flame retardant and tackifier. Adhesive compound, make the moisture content of finish layer dry to 5%; Wherein, waterproof agent is 0.05% of finish layer weight, antifungal agent is 0.01% of finish layer weight, flame retardant is 0.04% of finish layer weight %, the tackifier is 0.5% of the weight of the facing layer;

[0021] (2) Choose a slab layer with a thickness of 12mm, length*width=2450*1230mm, and evenly pave the decorative layer in step (1) on the upper and lower surfaces of the slab layer, and the amount of coating on one side is 100g / m 2 , the amount of pavement is 0.5kg / m 2 , pavement t...

Embodiment 2

[0024] A method for manufacturing a composite wood-based panel with anti-corrosion, anti-mildew and high flame retardancy, comprising the following steps:

[0025] (1) The facing layer is glued with polyurethane adhesive, formaldehyde-free biomass adhesive or trialdehyde glue (urea formaldehyde, phenolic formaldehyde, melamine formaldehyde) and water repellant, antifungal agent, flame retardant and tackifier. Adhesive compound, make the moisture content of facing layer dry to 10%; Wherein, waterproof agent is 2% of facing layer weight, antifungal agent is 1.5% of facing layer weight, flame retardant is 1% of facing layer weight %, the tackifier is 1% of the weight of the facing layer;

[0026] (2) Select a slab layer with a thickness of 12mm and length*width=2550*1250mm, and evenly pave the decorative layer in step (1) on the upper and lower surfaces of the slab layer, and the amount of coating on one side is 110g / m 2 , the amount of pavement is 2kg / m 2 , pavement thicknes...

Embodiment 3

[0029] A method for manufacturing a composite wood-based panel with anti-corrosion, anti-mildew and high flame retardancy, comprising the following steps:

[0030] (1) The facing layer is glued with polyurethane adhesive, formaldehyde-free biomass adhesive or trialdehyde glue (urea formaldehyde, phenolic formaldehyde, melamine formaldehyde) and water repellant, antifungal agent, flame retardant and tackifier. Adhesive compounding, so that the moisture content of the facing layer is dried to 15%; among them, the waterproof agent is 0.05-3.4% of the weight of the facing layer, the anti-fungal agent is 0.01-4.5% of the weight of the facing layer, and the flame retardant is the weight of the facing layer 3% of the weight of the layer, the tackifier is 1.5% of the weight of the facing layer;

[0031] (2) Choose a slab layer with a thickness of 18mm, length*width=2750*1310mm, evenly pave the finishing layer in step (1) on the upper and lower surfaces of the slab layer, and the amoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap