Peacock tail spread type shell inlaying composite board and manufacturing process thereof

A technology for peacock opening and production process, which is applied in decorative arts, special decorative structures, covering/lining and other directions, and can solve the problems of radiation, no color and shape, and poor waterproof performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

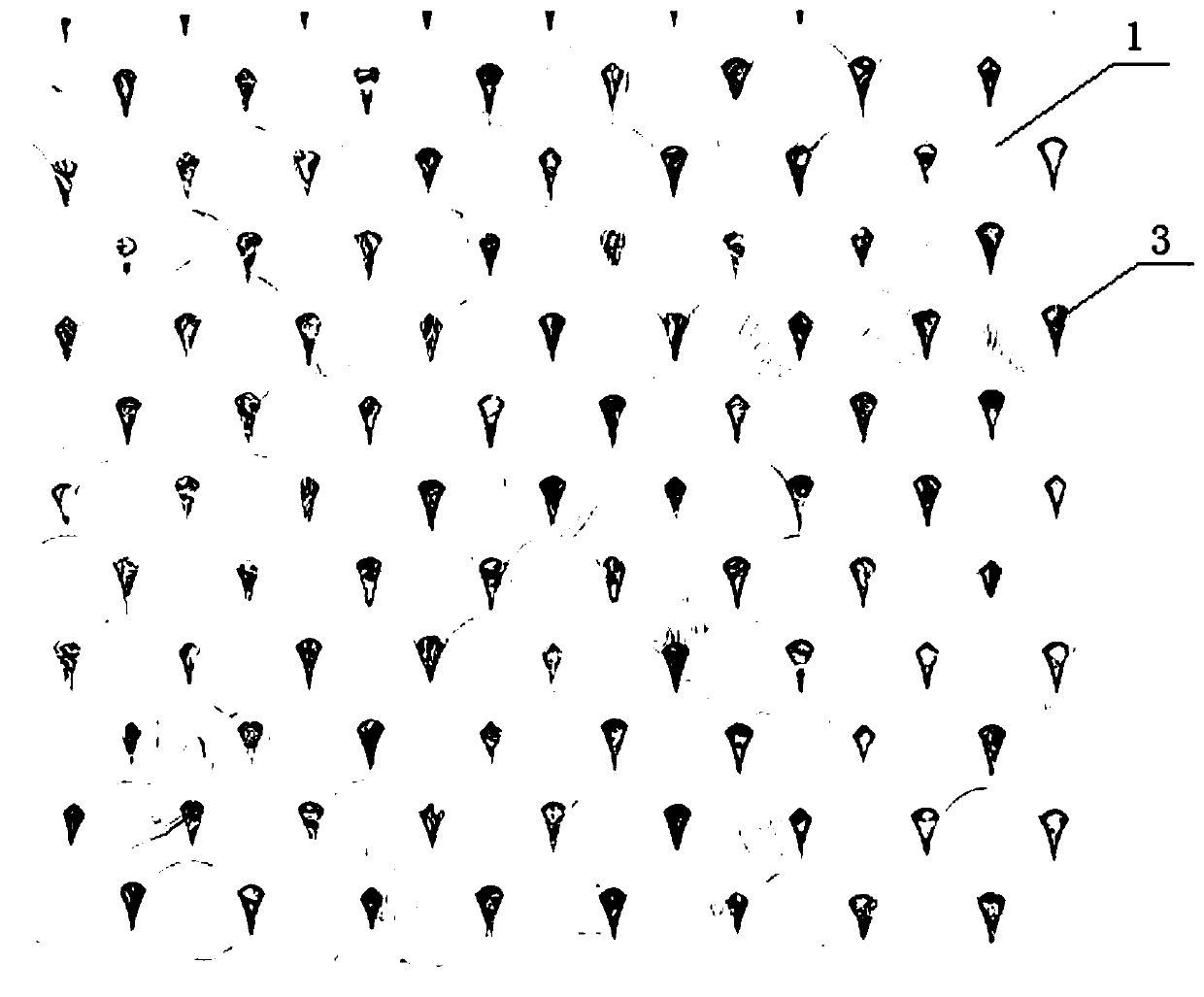

[0032] Based on the above description, the present invention also provides an embodiment: a manufacturing process of a peacock-opened shell inlaid composite board, comprising the following steps:

[0033] The first step: the natural shell piece 1 is processed into particles with a size slightly larger than the plane size of the product by a cutting machine;

[0034] The second step: pass the cut shell piece 1 through two cars, grind away the surface impurities, and determine its thickness;

[0035] Step 3: Put the shell piece 1 that has passed through the second car into a mold with the same product size and shape, and directly press it out;

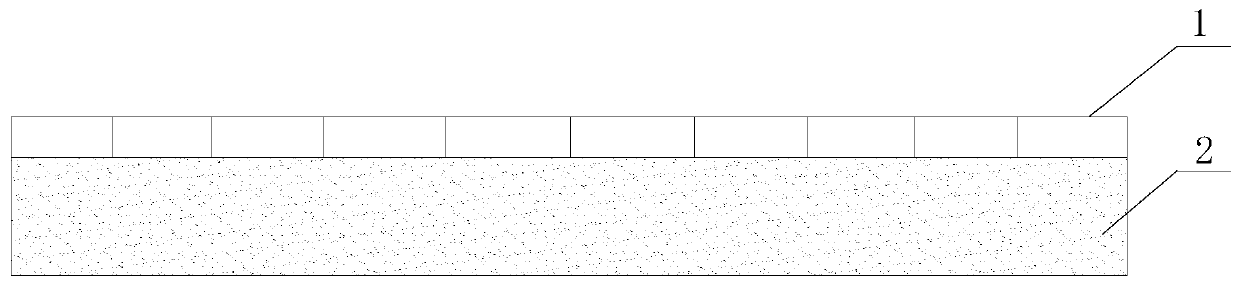

[0036] Step 4: Paste the shell piece 1 on the prepared substrate 2, put it in a dryer to dry, or put it at room temperature and wait for natural drying;

[0037] Step 5: Take out the dried product, start carving according to the product structure, and inlay shell pieces 1 of different colors according to the desired product shape; fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com