Portable bagging device

A bagging device and a convenient technology, applied in the field of convenient bagging devices, can solve problems such as poor efficiency, increase production cost, and advance packaging of fresh flowers and trees, save labor costs, improve work efficiency, and facilitate physical coordination. effect of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

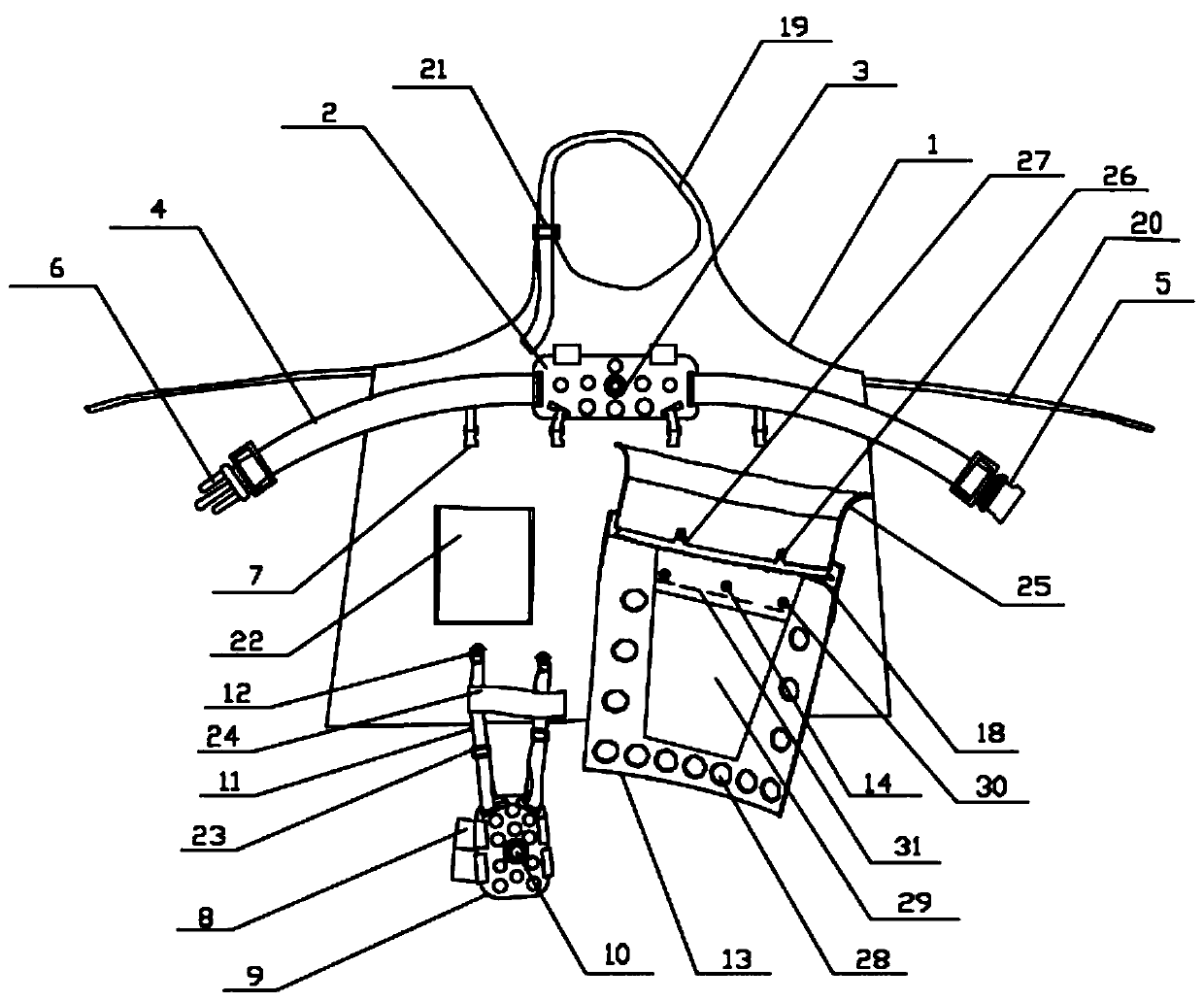

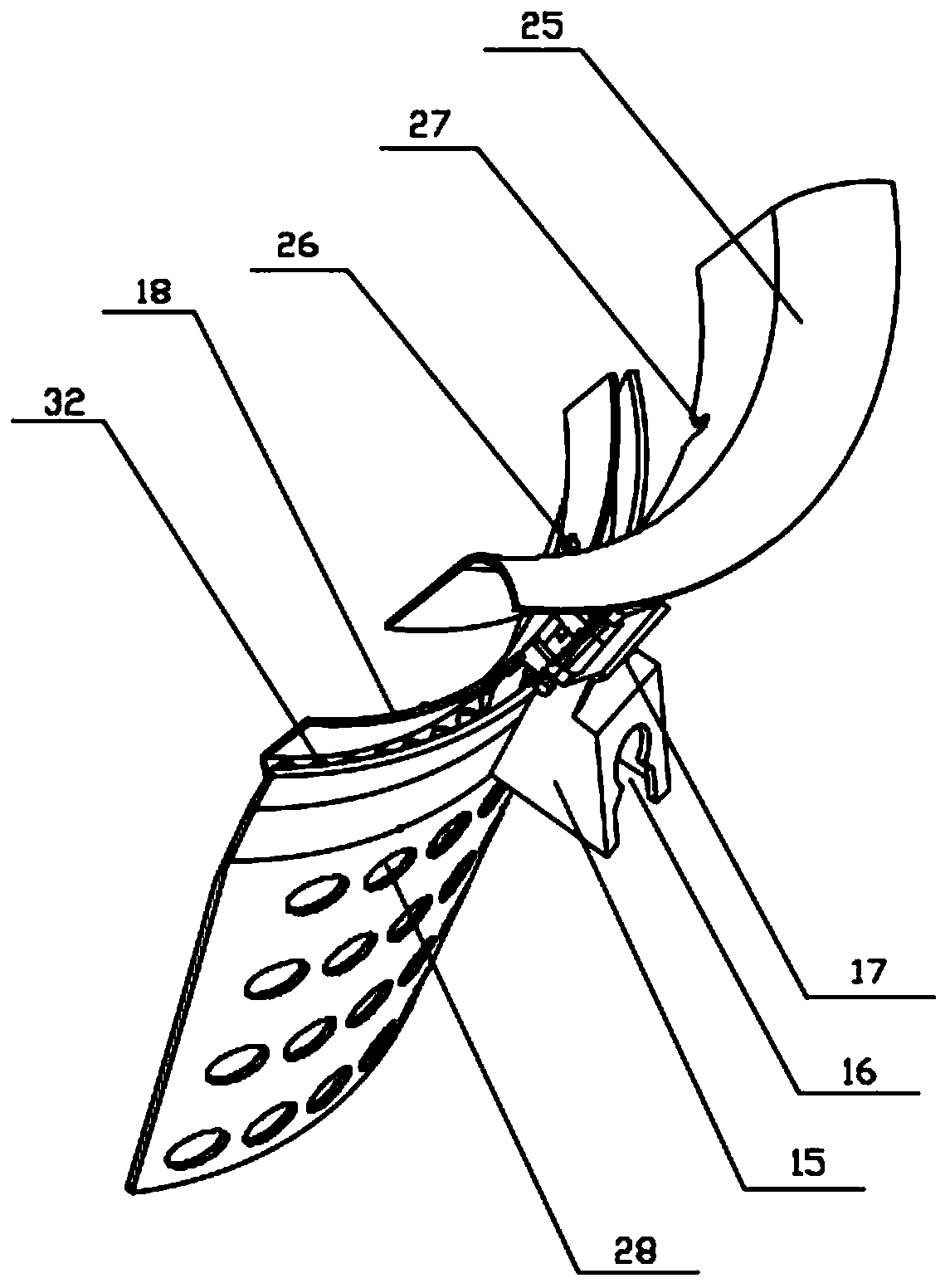

[0026] Such as Figure 1-Figure 4 The shown portable bagging device includes a bag clamping device and an installation device connected with the bag clamping device.

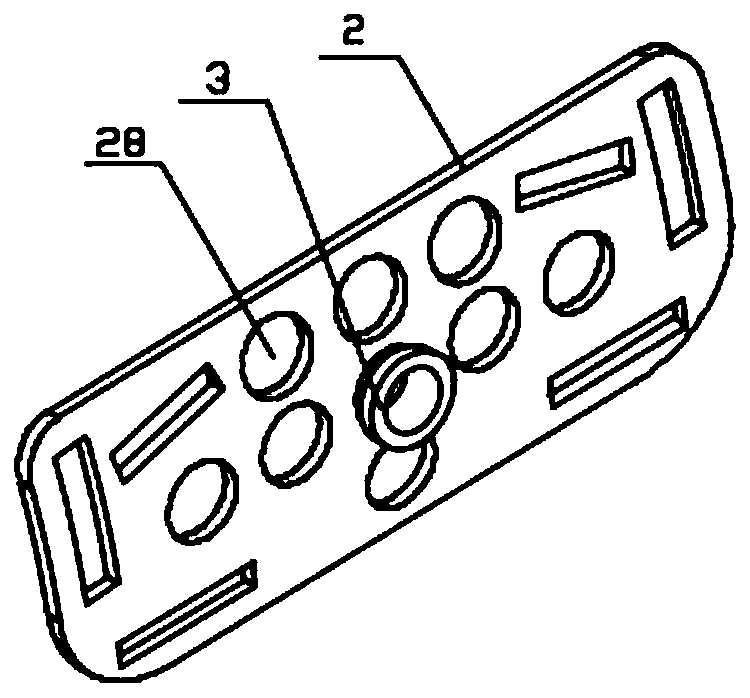

[0027] Described bag clamping device comprises bag clamping main board 13, and the upper part of one side of described bag clamping main board 13 is provided with the bag-releasing protrusion 14 that matches with the through hole 30 on the packaging bag 29, thereby can pack the packaging bag of batch 14 are enclosed within on the bag protrusion 14. A connecting seat 15 is provided on the upper part of the other side of the pocket main board 13 , and a connecting groove 16 for connecting with the installation device is opened at the bottom of the connecting seat 15 . The side of the connection seat 15 with the connection groove 16 is arranged as an inclined plane. A spring clip 17 is fixedly arranged in the middle of the top of the pocket main board 13, and one end of the spring clip 17 is fixedly connected to ...

Embodiment 2

[0037] Such as figure 2 , Figure 5 and Figure 6 As shown, in this embodiment, only the structure of the installation device is changed without changing other structures of the first embodiment. In this embodiment, the installation device includes a base 33 on which a lower main pipe is fixed. 34. Three connecting rods 35 are uniformly arranged on the side of the base 33, one end of each connecting rod 35 is hingedly connected with the side of the base 33, and the other end of each connecting rod 35 is respectively connected to three supporting The middle part of the rod 36 is hingedly connected, and the upper ends of the three support rods 36 are respectively hingedly connected with the peripheral wall of the first movable sleeve 37 which is movably sleeved on the lower main pipe 34, and the first movable sleeve 37 passes through the first The top wire 38 is fixedly connected with the lower main pipe 34 .

[0038] The upper part of the lower main pipe 34 is inserted with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com