Rubber dam for water storage reservoir and construction method of rubber dam

A technology for rubber dams and reservoirs, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of firmness of dam bags, deformation and damage of anchoring shafts, gaps, etc., and achieve the effect of avoiding fixing defects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

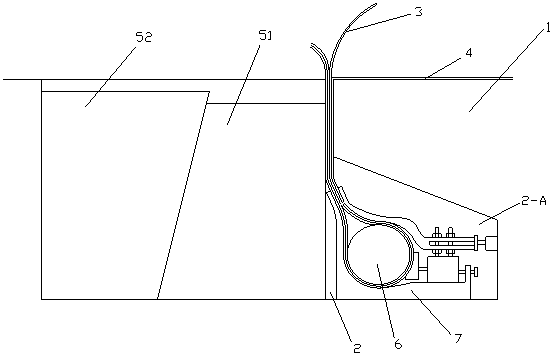

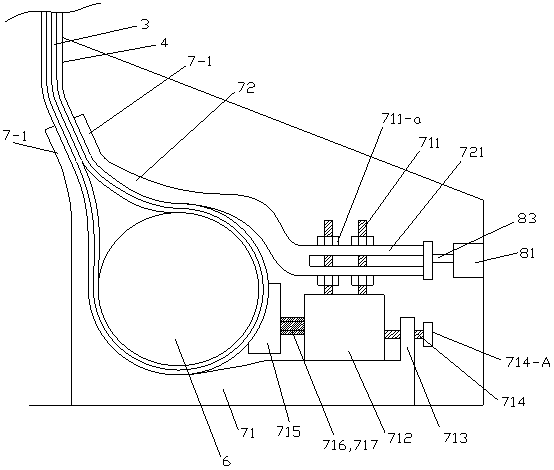

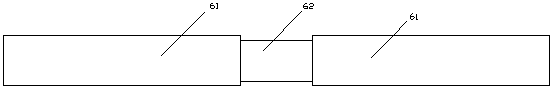

[0036] refer to Figure 1-Figure 4 , as a new type of dam, the rubber dam has the following outstanding advantages compared with other types of gates and dams: ① Save three materials. Generally, 30% to 50% of steel can be saved, 20% to 50% of cement can be saved, and 60% of wood can be saved. ②The cost is low. Compared with the cost of steel structure gates of the same scale, the investment can generally be reduced by 30% to 70%. ③No water blocking and good water stopping effect. The main disadvantages of rubber dams are poor firmness and easy aging. This is because the main material of the dam bag is adhesive tape with a thickness of several millimeters. Although it is relatively flexible, it is not robust enough to be easily damaged by machinery. It needs to be carefully maintained during use to prevent it from being stabbed by sharp objects. Using the rubber dam project to increase the amount of groundwater resources in the riverside area is an important way to solve th...

Embodiment example 2

[0047] Before the construction of the rubber dam, the following preparations are required:

[0048] It should include two aspects: one is civil engineering; the other is the customization of rubber dam bags. Civil engineering involves the construction of cofferdams, construction diversion, excavation of foundation pits, foundation floor construction, anchor trench construction, and laying of related control and observation pipelines. The civil construction process flow is: clearing the river bed→site layout→damming and intercepting (or repairing cofferdam)→setting construction drainage→excavating the foundation pit→pouring the foundation floor, bank wall, stilling basin (apron)→the later stage of the anchoring groove Concrete → masonry bedding, seamanship, slope protection → burying bolts and pipes, etc. For dam bags, the dam bags need to be inspected to ensure the quality of the dam bags. After leaving the factory, it is necessary to strictly check whether their quality and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com