A Buckling Constrained Brace of Triple Round Steel Tubes

A buckling restraint, round steel pipe technology, applied in building types, buildings, building components, etc., can solve the problems of unable to support inner core restraint, unable to restrain the torsional deformation of energy-consuming circular pipes, etc., achieve light weight, restrain torsional deformation, improve The effect of fatigue performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

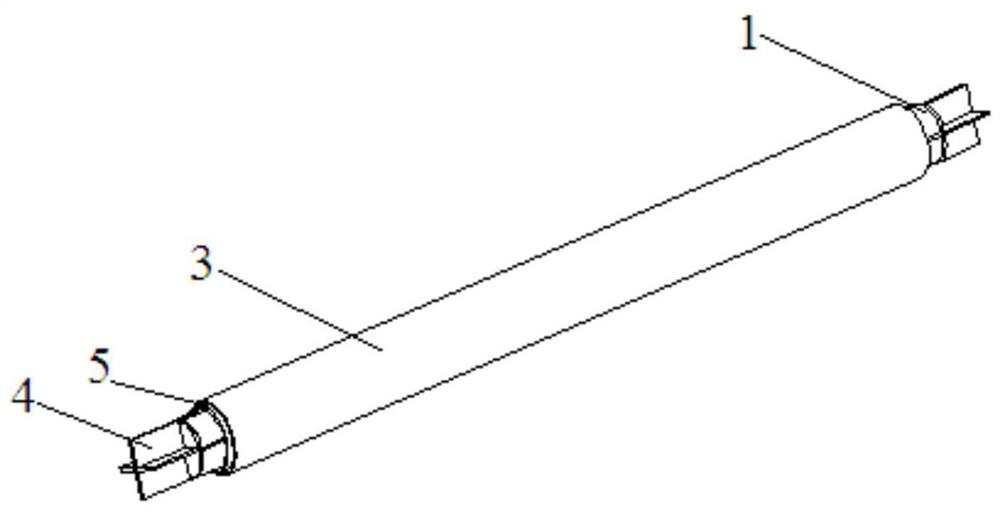

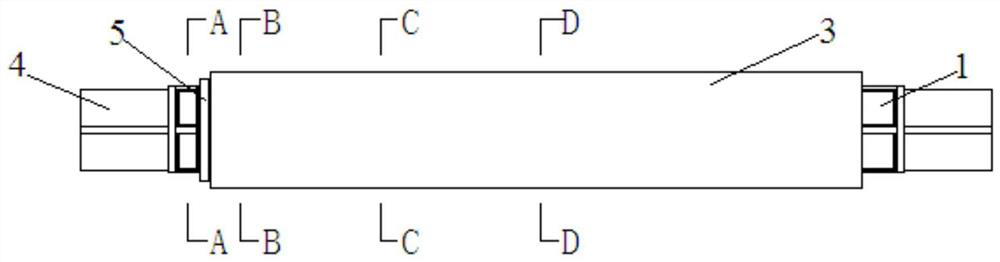

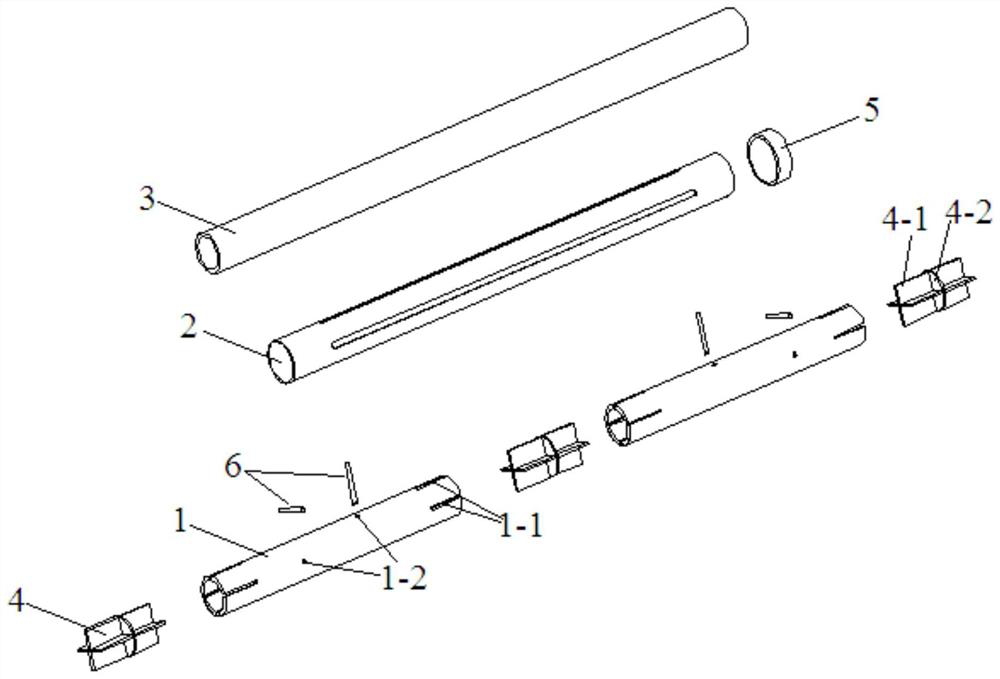

[0033] Embodiment 1: This embodiment is a triple round steel tube buckling restraint support, which consists of 2 inner restraint pipes 1, 1 energy dissipation pipe 2, 1 outer restraint pipe 3, 3 inserts 4, and 1 pad The ring 5 and 4 torsion limit rods 6 are composed;

[0034] The inner restraint pipe 1 is a round steel pipe, and both ends of the inner restraint pipe 1 are provided with cross-shaped slot holes 1-1, and the cross-shaped intersection of the cross-shaped groove holes 1-1 is on the axis of the inner restraint pipe 1, at Two pairs of torsion limit holes 1-2 are opened in the middle of the inner restraint tube 1 in sequence along the longitudinal direction. The line connecting the centers of the -2 circles is cross-shaped; the length of the cross-shaped slot hole 1-1 is 1.5 times the expected deformation of the triple round steel tube buckling restraint support;

[0035]The energy dissipation pipe 2 is a circular steel pipe, and four slots are longitudinally opened...

specific Embodiment approach 2

[0047] Embodiment 2: The difference between this embodiment and Embodiment 1 is: the A=D 1 -8 to 10 mm and others are the same as in the first embodiment.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the shortest distances between the two pairs of torsion limiting holes 1-2 and the end of the inner restraint tube 1 are equal. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com