Anti-collapse reinforcement method for frame-anti-buckling support system

A technology of anti-buckling support and system, applied in the direction of earthquake resistance, building maintenance, building components, etc., can solve the problem that H-shaped steel frame columns cannot provide the main structure, improve safety reserve and anti-collapse ability, reduce construction difficulty, prevent failure The effect of stabilizing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

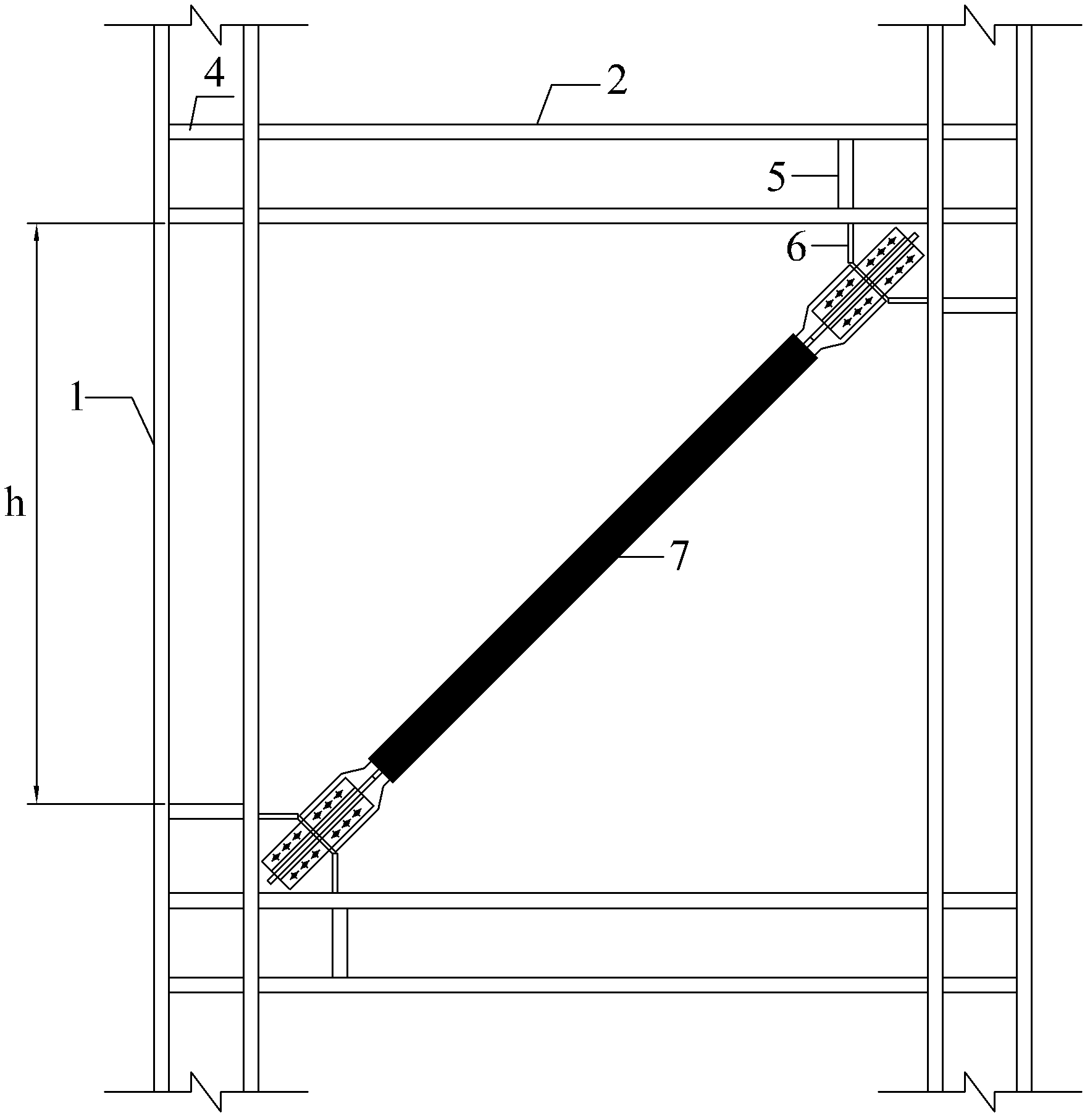

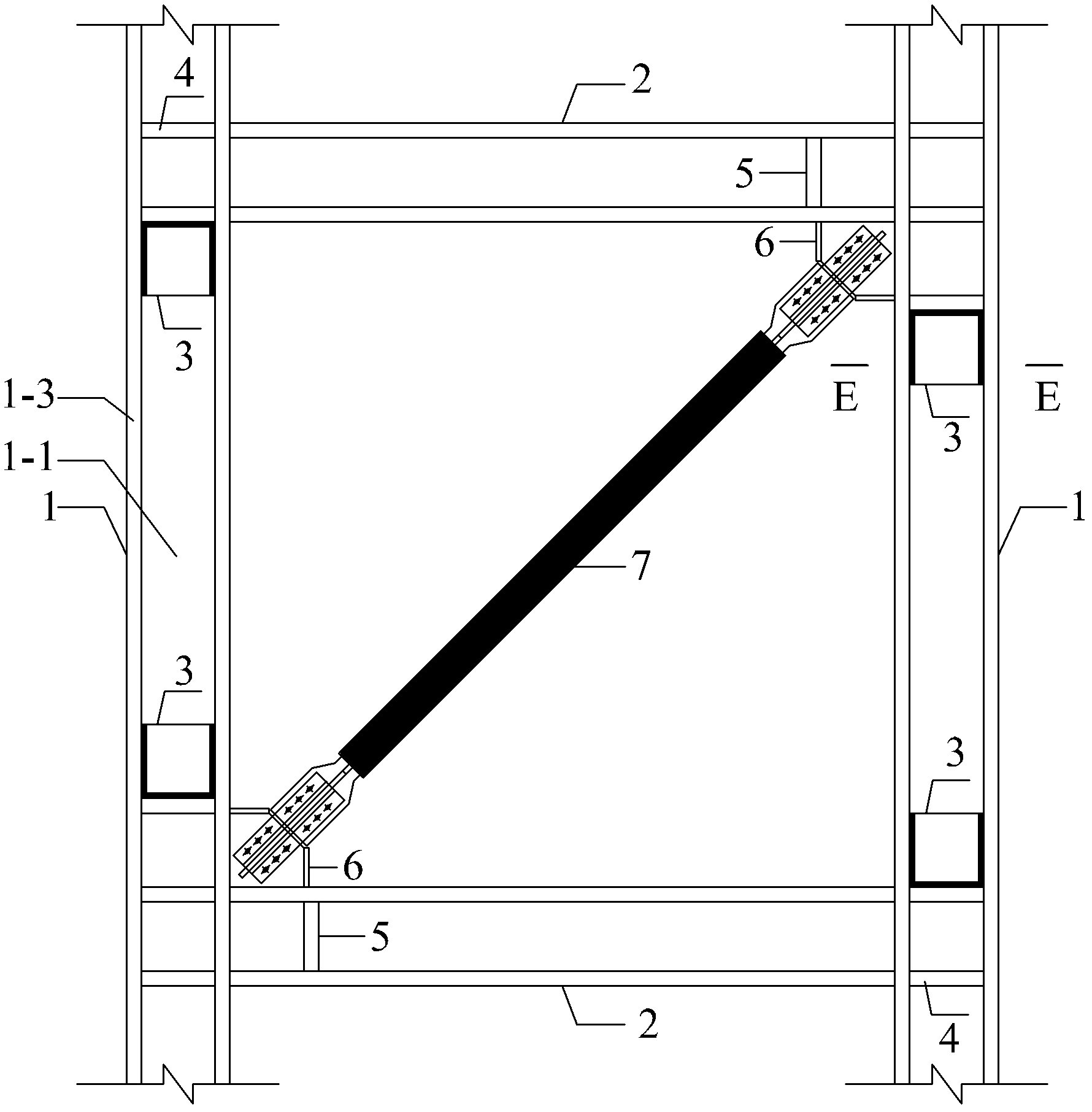

[0014] Specific implementation mode one: combine Figure 2 to Figure 11 Explain, a frame-buckling-resistant support system anti-collapse reinforcement method of this embodiment, the reinforcement method is implemented according to the following steps:

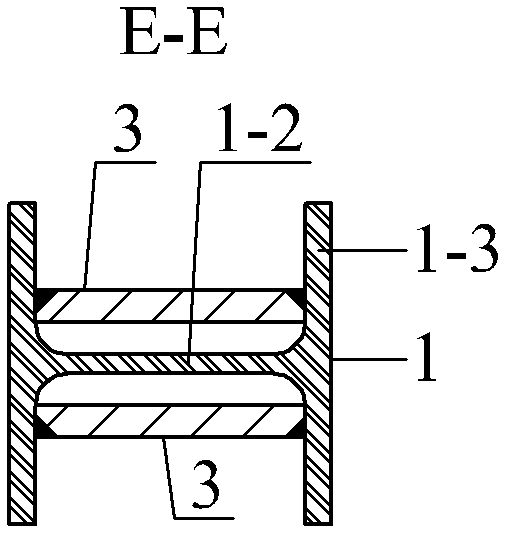

[0015] Step 1: each groove 1-1 of the H-shaped steel frame column 1 between two adjacent frame beams 2 in the all-steel frame-buckling-resistant bracing system to be reinforced (there are two grooves 1-1 in the H-shaped steel frame column 1 Groove 1-1, two grooves 1-1 are surrounded by web 1-2 and two flanges 1-3), and two longitudinal stiffeners 3 are added inside (to ensure that the end of H-shaped steel frame column 1 does not damaged in the middle section), the two longitudinal stiffeners 3 are arranged at the upper and lower ends of the H-shaped steel frame column 1, and the two longitudinal stiffeners 3 arranged at the upper end of the H-shaped steel frame column 1 are correspondingly arranged, and are arranged at The tw...

specific Embodiment approach 2

[0019] Specific implementation mode two: combination figure 2 , image 3 , Figure 7 and Figure 10 Note that in step 1 of this embodiment, the longitudinal stiffeners 3 are made of steel plates. Other method steps are the same as those in the first embodiment.

specific Embodiment approach 3

[0020] Specific implementation mode three: combination image 3 with Figure 10 Note that in step 1 of this embodiment, the sum of the cross-sectional areas of the two longitudinal stiffeners 3 arranged at the upper end of the H-shaped steel frame column 1 is 1.0 to 1.2 times the cross-sectional area of the H-shaped steel frame column 1; The sum of the cross-sectional areas of the two longitudinal stiffeners 3 at the lower end of the frame column 1 is 1.0-1.2 times the cross-sectional area of the H-shaped steel frame column 1 . By setting longitudinal stiffeners, the reinforced area of the H-shaped steel frame column can be in the elastic stage during the whole working process, ensuring that the reinforced area of the H-shaped steel frame column will not fail before the middle section of the H-shaped steel frame column, which is beneficial to the mechanical properties and energy consumption of the structural system full play of ability. Other method steps are the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com