Cast-in-situ facing concrete structure based on WISA formwork system and construction method thereof

A technology of facing concrete and formwork system, which is applied in the direction of building structure, formwork/formwork/work frame, formwork/formwork/work frame connectors, etc. It can solve problems such as construction and installation together, and achieve Good mold release effect, low cost and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055]The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description.

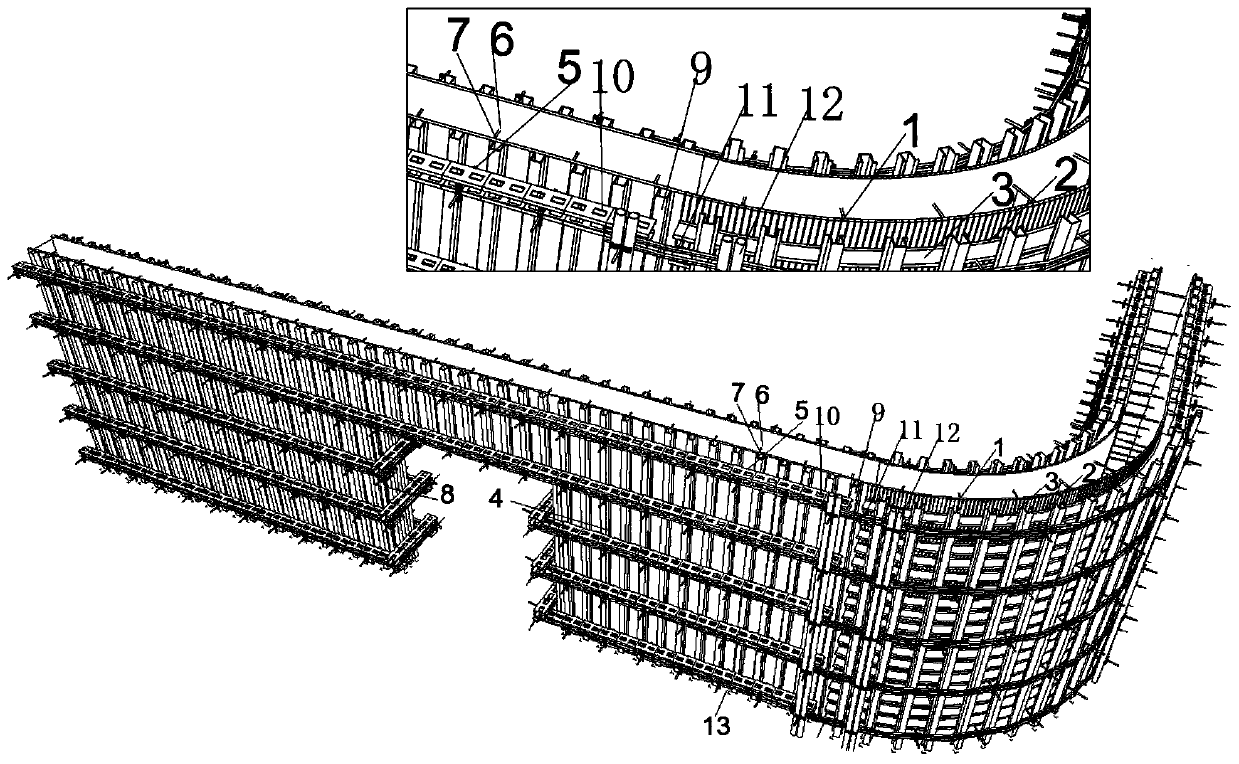

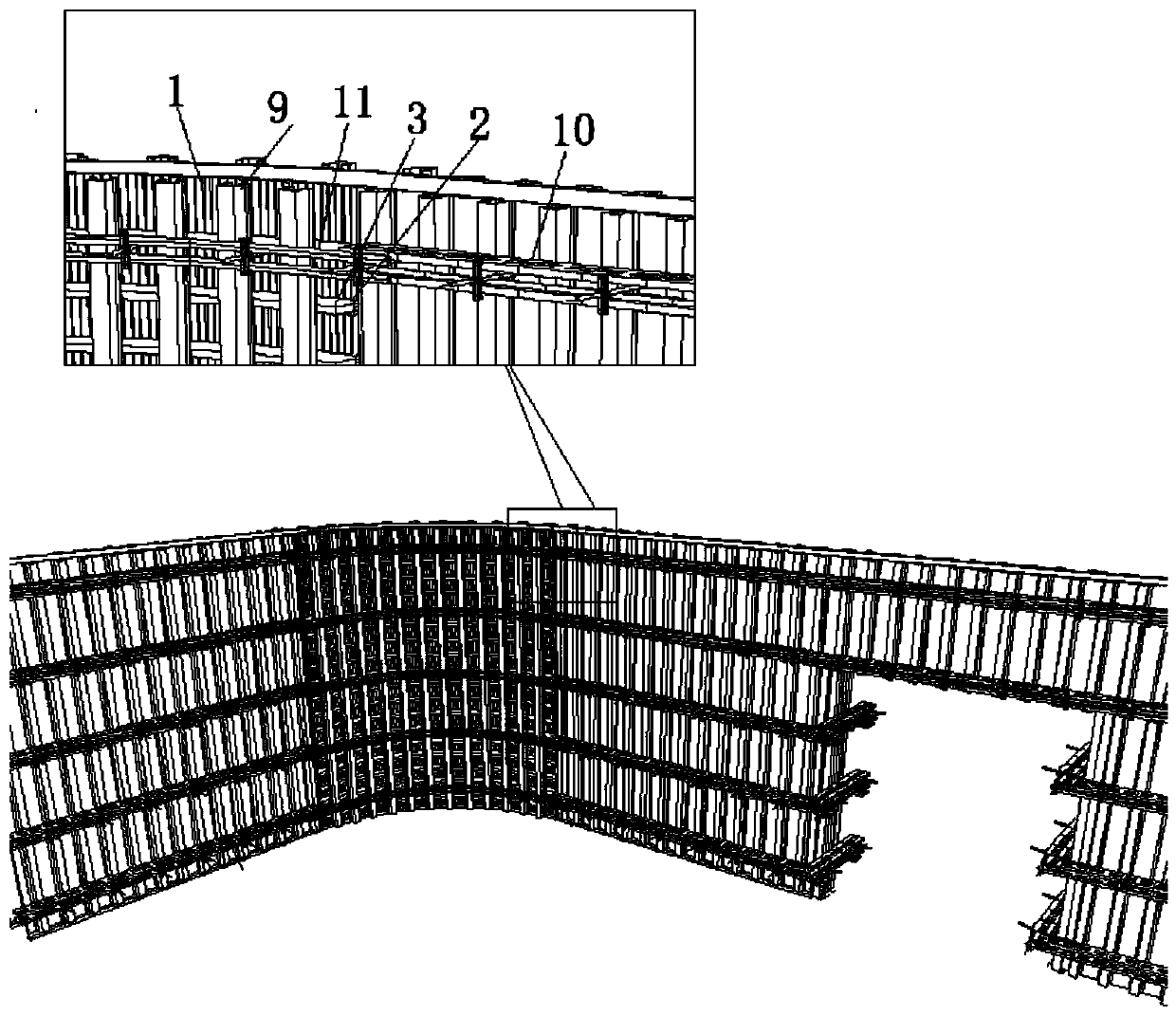

[0056] See attached Figure 1-14 , a method for constructing a cast-in-place facing concrete structure based on the WISA formwork system, comprising the following steps:

[0057] Step 1. Consider water, electricity, buildings, and structures to draw a detailed drawing, and confirm the detailed drawing;

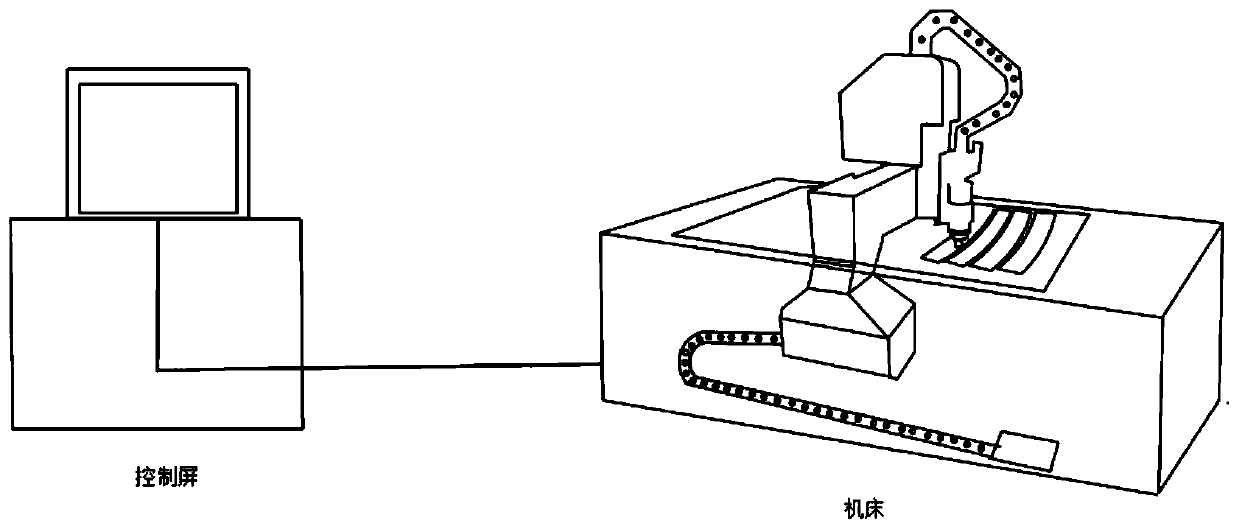

[0058] Step 2, using the attached image 3 The machine shown in the figure cuts grooves with a width of 5mm and a depth of 10mm every 25mm on the formwork 1 away from the concrete surface. Specifically, the function of the grooves is to enable the formwork to bend without breaking, and to drill the reserved holes ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com