Oil film drifting simulation device

A simulation device and oil film technology, applied in the field of oil film drift simulation device, can solve problems such as real-time interpretation, inability to use tracers, etc., and achieve the effects of reducing water resistance, reducing measurement interference, and increasing rotational inertia

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0118] Continuous or batch release of a single device under good GPSR signal conditions in water areas

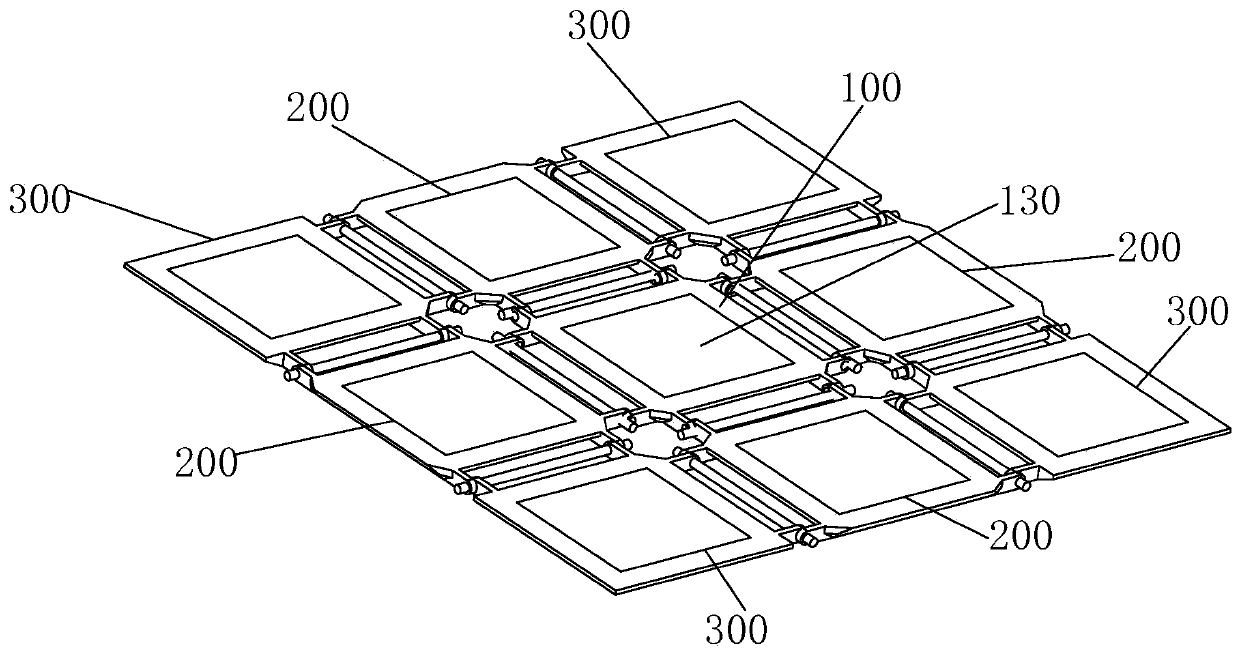

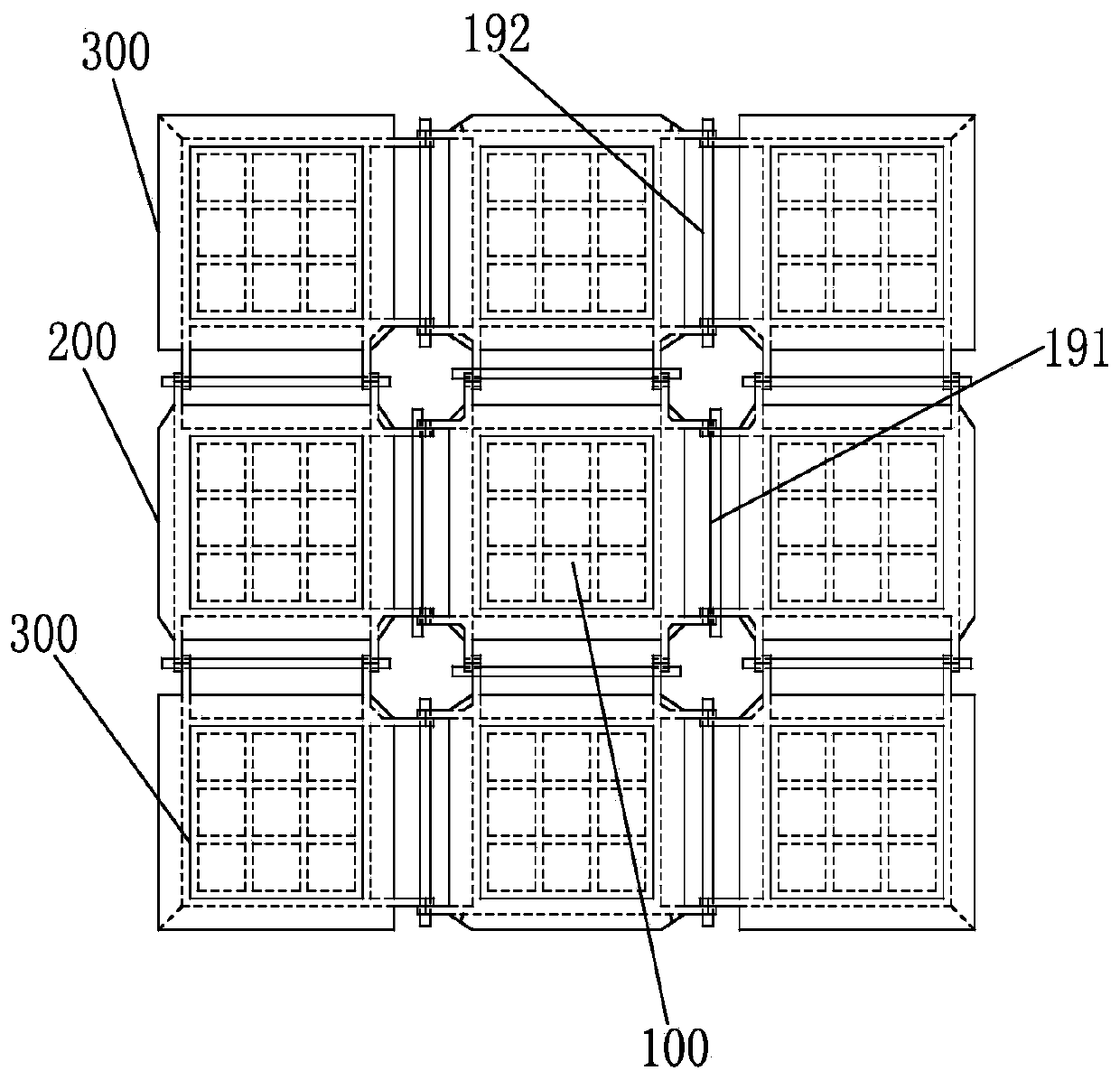

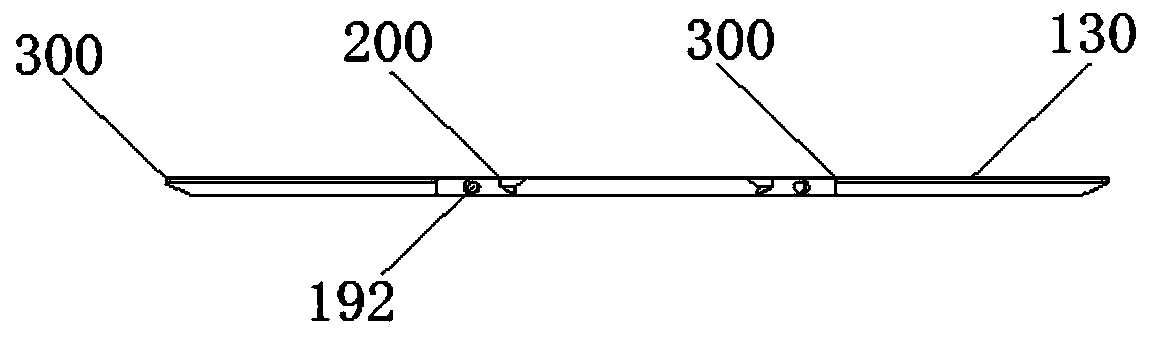

[0119] Under specified meteorological and hydrological conditions, connect battery pack 700 and GPS module 410, GPRS data module 440, acceleration sensing module 420, temperature sensing module 430 and data storage module 800, set each module parameter; GPS module 410 and GPRS data module 440 regularly returns position data; according to the buoyancy of the local water body, place counterweights and adjust the central component 100 to achieve buoyancy balance; under still water conditions, the water level is just below the central skirt 160, the middle skirt 210, and the edge The upper edge of the upper skirt 220, the middle corner skirt 310 and the edge corner skirt 320. Tighten the bolts to seal the assembly cover plate 130 and the central assembly 100 . Adjust the counterweights of the side assembly 200 and the corner assembly 300 to achieve a ratio of 2:1 between the m...

Embodiment 3

[0122] Single device launch in water without GPSR signal:

[0123] Under the specified meteorological and hydrological conditions, connect the battery pack 700 and the inter-device interconnection networking module, the acceleration sensing module 420, the temperature sensing module 430 and the data storage module 800, and set the parameters of each module; the GPS module 410 and the inter-device interconnection networking The module returns position data regularly. According to the buoyancy of the water body in the local waters, place the counterweight and adjust the central assembly 100 to achieve buoyancy balance. The upper edge of the upper skirt 310 and the edge corner skirt 320. Tighten the bolts to seal the assembly cover plate 130 and the central assembly 100 . Adjust the weights of the side assembly 200 and the corner assembly 300 to achieve a ratio of 2:1 between the mass of the side assembly 200 and the mass of the central assembly 100, and a ratio of 3:1 between ...

Embodiment 3

[0126] Continuous or batch release of the device under the condition of no GPSR signal in the water area:

[0127] Under the specified meteorological and hydrological conditions, connect the battery pack 700 and the inter-device interconnection networking module, the acceleration sensing module 420, the temperature sensing module 430 and the data storage module 800, and set the parameters of each module. The GPS and the inter-device interconnection networking module regularly return location data. According to the buoyancy of the water body in the local waters, place the counterweight and adjust the central assembly 100 to achieve buoyancy balance. The upper edge of the upper skirt 310 and the edge corner skirt 320. Tighten the bolts to seal the assembly cover plate 130 and the central assembly 100 . The weights of the side assemblies 200 and the corner assemblies 300 are adjusted to achieve a mass to center assembly 100 ratio of 2:1 and 3:1. Tighten the bolts to seal the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com