Test probe assembly and test socket

A technology for testing probes and probes, used in electronic circuit testing, measuring electricity, measuring devices, etc., to achieve the effects of easily shielding noise, improving noise shielding efficiency, and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

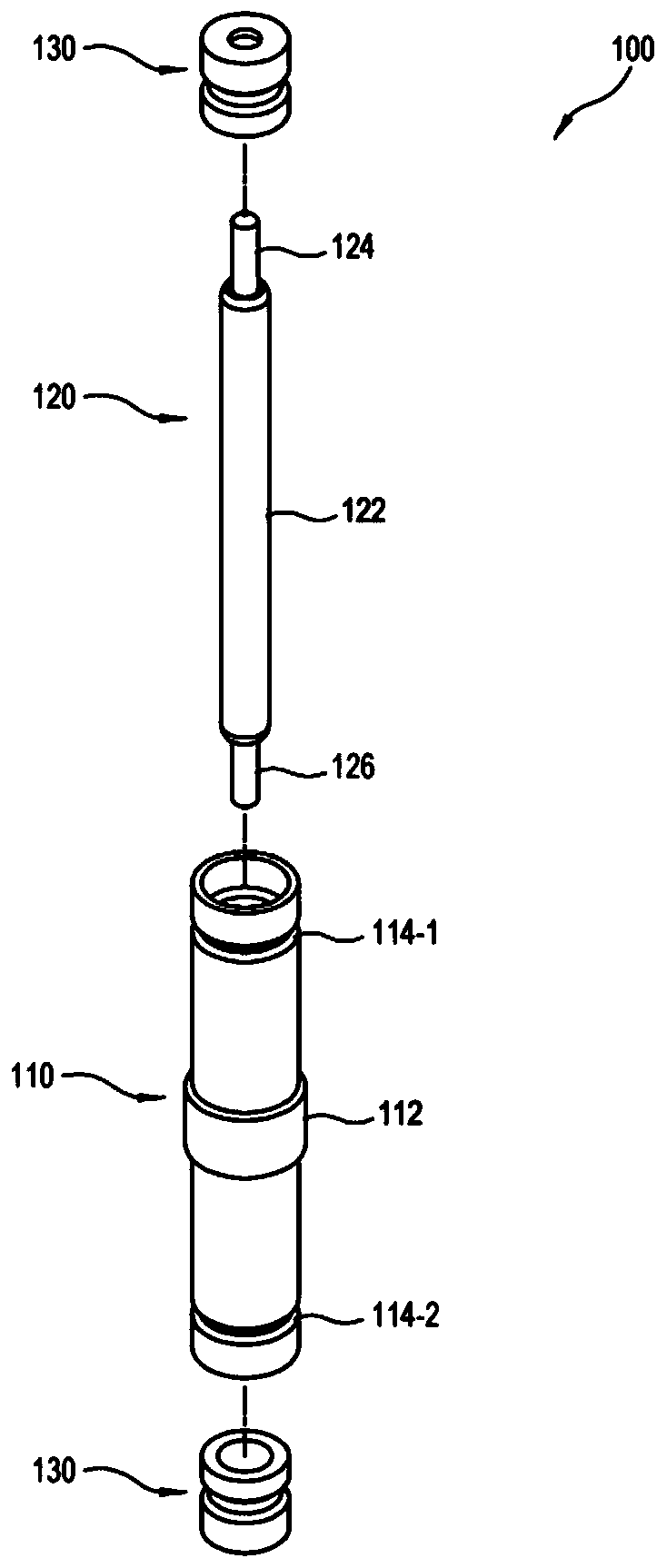

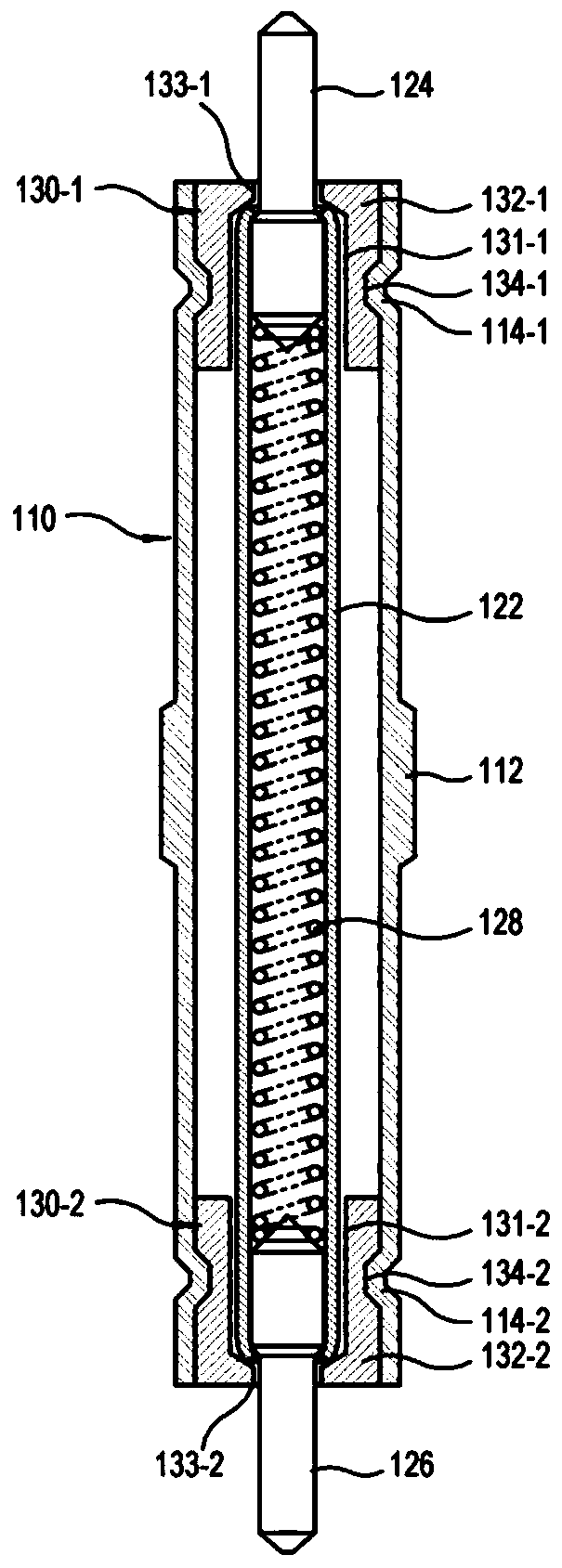

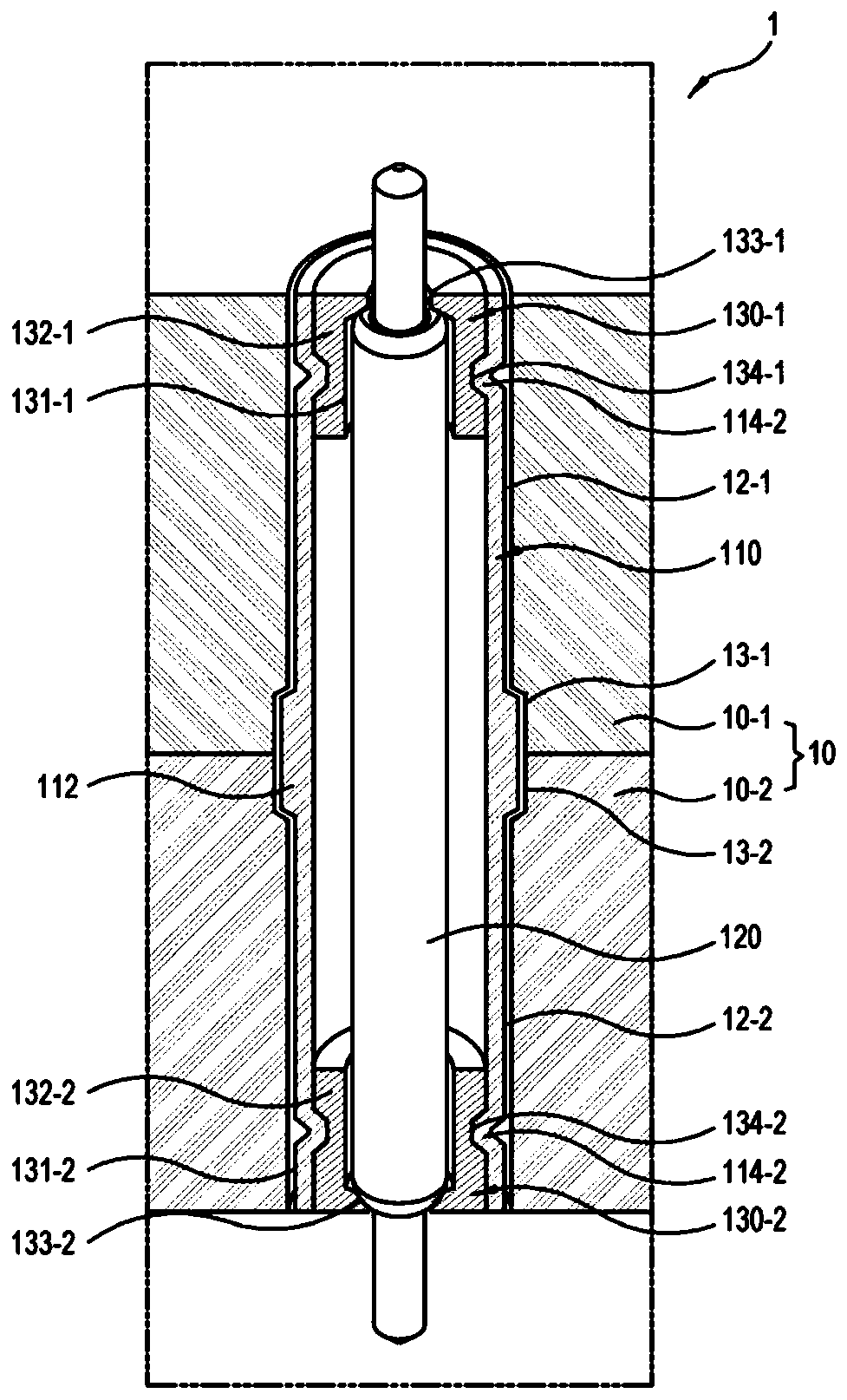

[0042] Such as image 3 As shown in , the tube 110 of the test probe module 100 is filled in the test socket 1 over the entire thickness of the test socket 1 , thereby preventing noise interference between adjacent test probe modules 100 as much as possible. In addition, when a certain test probe module 100 fails or collapses, only the corresponding test probe module 100 can be replaced. That is, according to the first embodiment of the present invention, an insulating support member mounted to the top and bottom surfaces of the conductive block to support the probes is not included.

[0043] Figure 4 and 5 They are respectively cross-sectional views of the test socket 1 to which the test probe module 100 according to the second embodiment and the third embodiment of the present invention is applied. In these examples, with Figure 1 to Figure 3 Parts that are partly the same as those of the illustrated first embodiment are denoted by the same numerals, and redundant desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com