Cleaning tool

A technology for cleaning tools and cleaning surfaces, applied in cleaning equipment, cleaning machinery, carpet cleaning, etc., can solve the problems of affecting cleaning effect and secondary pollution, and achieve the effects of guaranteed cleaning effect, high practicability, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

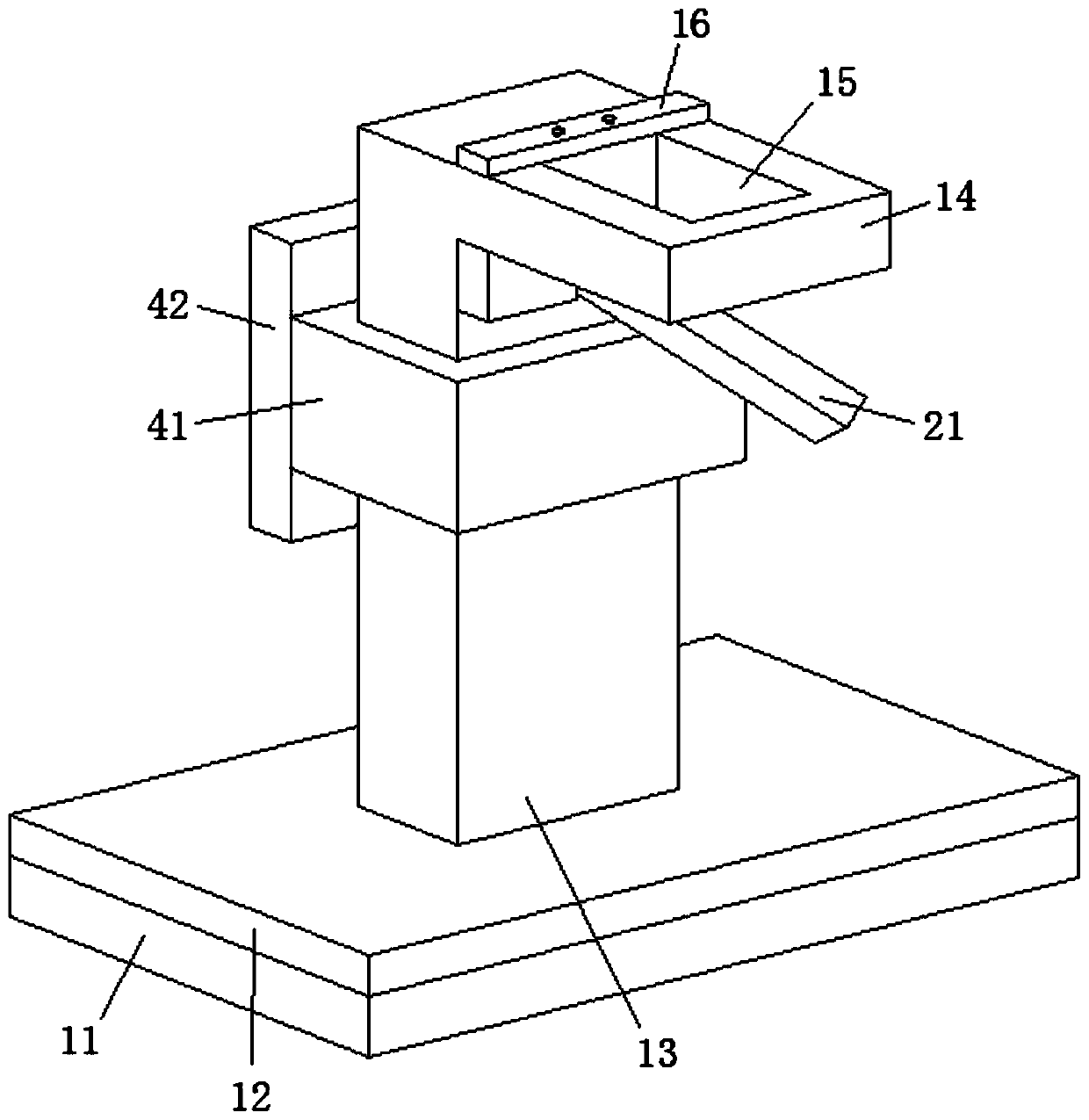

[0073] see Figure 11 As shown, the above-mentioned disclosed cleaning tool is installed in the housing (i.e. the structure shown in the dotted frame in the figure), and then a hand-held push rod is installed on the top of the housing.

[0074] Specifically, when in use, the hand-held push rod is used to push the cleaning tool to perform frictional cleaning of the cleaning surface. The cleaning surface mentioned here includes not only the ground, but also walls and the like.

[0075] It is easy to explain that the use method of this embodiment is the same as that of the existing manual mop, and the user does not need to deliberately change the operation habit of dragging the mop back and forth to avoid the problem of residual sewage.

Embodiment 2

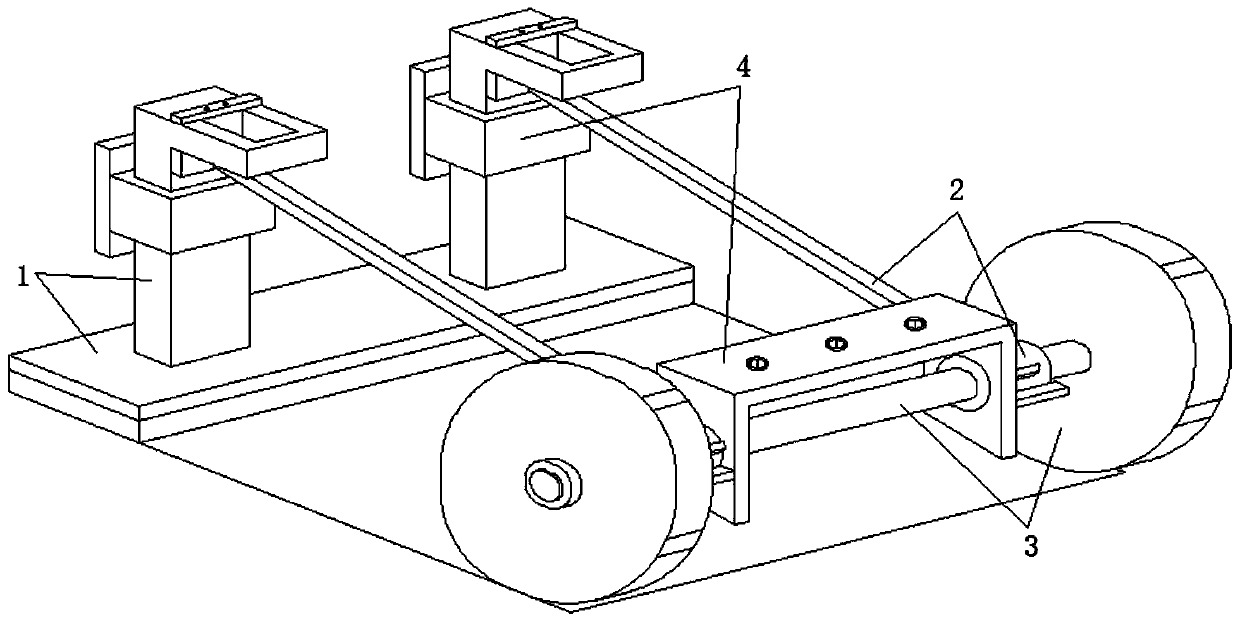

[0077] see Figure 12-Figure 13 As shown, the above-mentioned disclosed cleaning tool is installed in the housing (i.e. the structure shown in the dotted frame in the figure), and the mobile drive assembly 6 is also installed in the housing to cooperate with the mobile assembly 3 to realize the automatic movement of the cleaning tool.

[0078] Specifically, in this embodiment, refer to Figure 13 Regarding the mobile drive assembly 6, the driving motor and the driving group gear can be used in the form that the driving group gear is installed on the rotating shaft 31, and the driving group gear is driven by the driving motor to rotate, thereby realizing the driving of the rotating shaft 31 and other structures.

[0079] In summary, in the above state, the integral cleaning tool constitutes an automatic cleaning tool.

[0080] In addition, in this embodiment, a steering drive assembly is also installed at the bottom of the housing, refer to Figure 12 As for the steering driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com