Non-directional press-fit type glass slide cleaning device for experiment

A cleaning device and press-fit technology, which is applied in the field of non-directional press-fit glass slide cleaning devices for experiments, can solve the problems of difficult cleaning, lens quality damage, and low efficiency, and achieve fast and effective cleaning effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

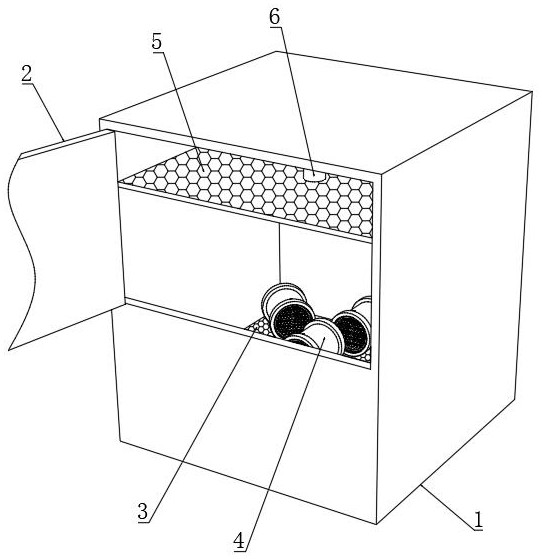

[0043] see figure 1 , an experimental non-directional pressing type glass slide cleaning device, including a cleaning box 1, the interior of the cleaning box 1 is fixedly connected with a mesh pad 3, the upper side of the mesh pad 3 is provided with a mesh pressure plate 5, and the mesh pressure plate 5 slides Connected to the inside of the cleaning box 1, an electric telescopic rod 6 is fixedly connected between the mesh pressure plate 5 and the inner top of the cleaning box 1, and the electric telescopic rod 6 is controlled by a controller (not shown in the figure) set at the outer end of the cleaning box 1. In order to control the position of the mesh platen 5, a plurality of layered soft elastic columns 4 are placed on the upper end of the mesh platen 3.

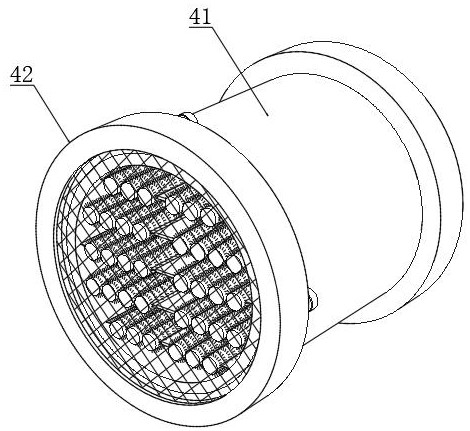

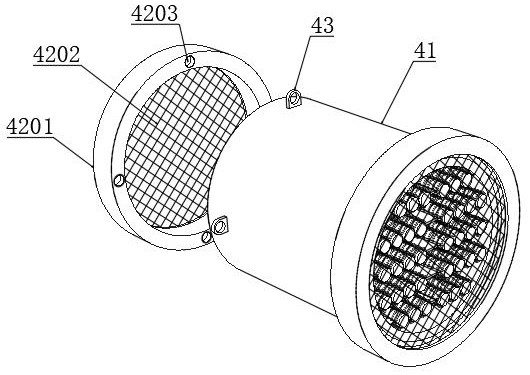

[0044] see figure 2 and image 3, the layered soft elastic column 4 includes a soft cylinder 41. The soft cylinder 41 is made of elastic rubber material and can be elastically deformed under the action of external for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com