Automatic square glass edge gluing equipment

A glass edge, automatic technology, used in coatings, devices for coating liquids on surfaces, etc., can solve problems such as uneven distribution of glue, low efficiency, and inability to ensure straight glue application, and achieve high quality and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

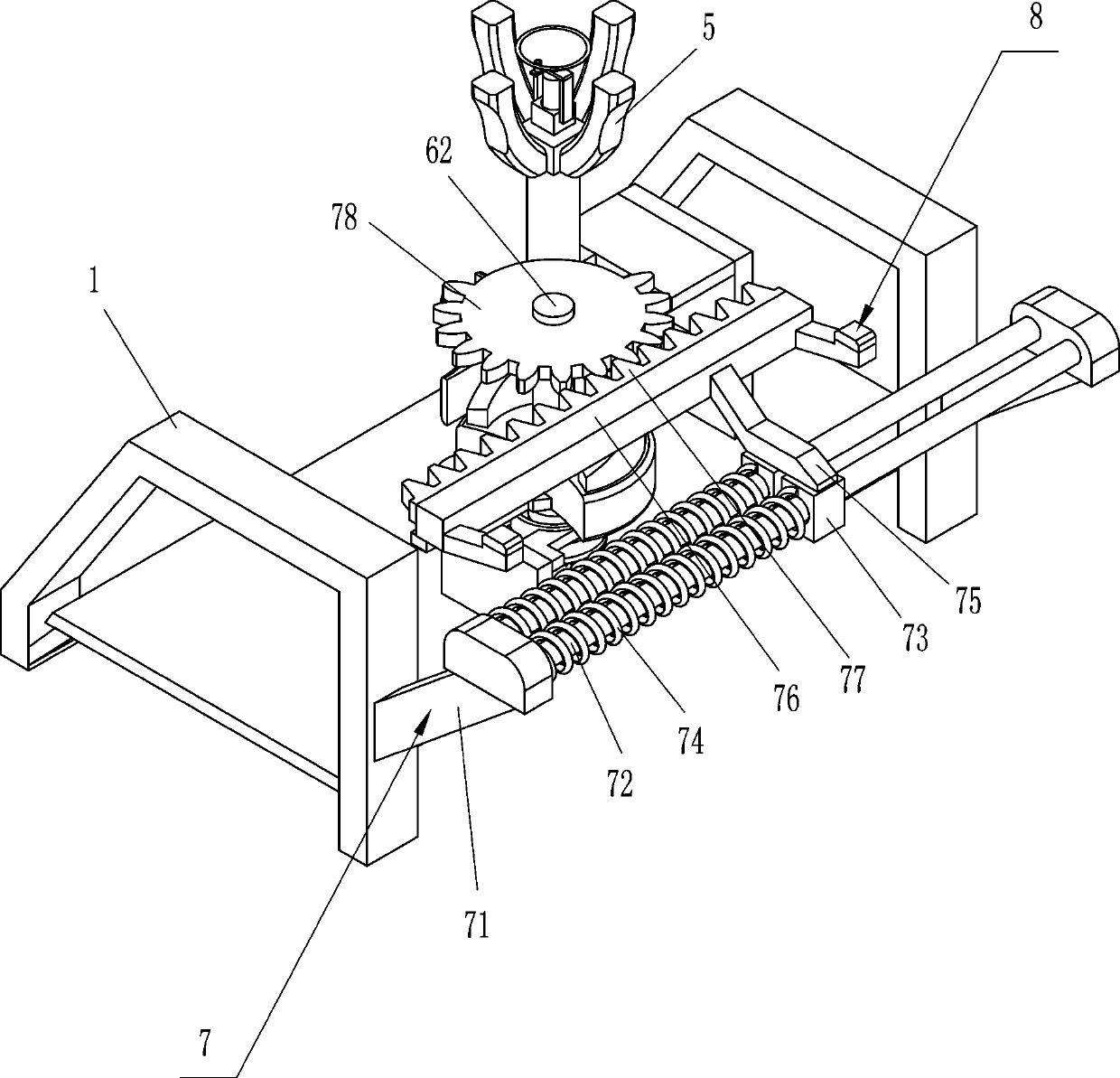

[0027] A square glass edge automatic glue coating equipment, such as Figure 1-2 As shown, it includes a bracket 1, a mounting plate 2, a first bearing seat 3, a first rotating rod 4, a placement frame 5, a driving device 6, a translation device 7, a backward moving device 8, a connecting frame 9, a connecting head 10, an external connection Glue pipe 11, telescopic pipe 12 and glue head 13, placing frame 5 is used to place glass, driving device 6 is used to provide power and intermittent transmission for equipment, translation device 7 is used to make glue head 13 move at a constant speed and perform automatic Resetting, moving back device 8 is used to offset the position of glue applicator 13, external glue pipe 11 is used to connect external glue source, telescopic tube 12 can be stretched, and glue applicator head 13 is used for gluing the glass side, specifically for:

[0028] A mounting plate 2 is connected between the lower sides of the two groups of brackets 1, a firs...

Embodiment 2

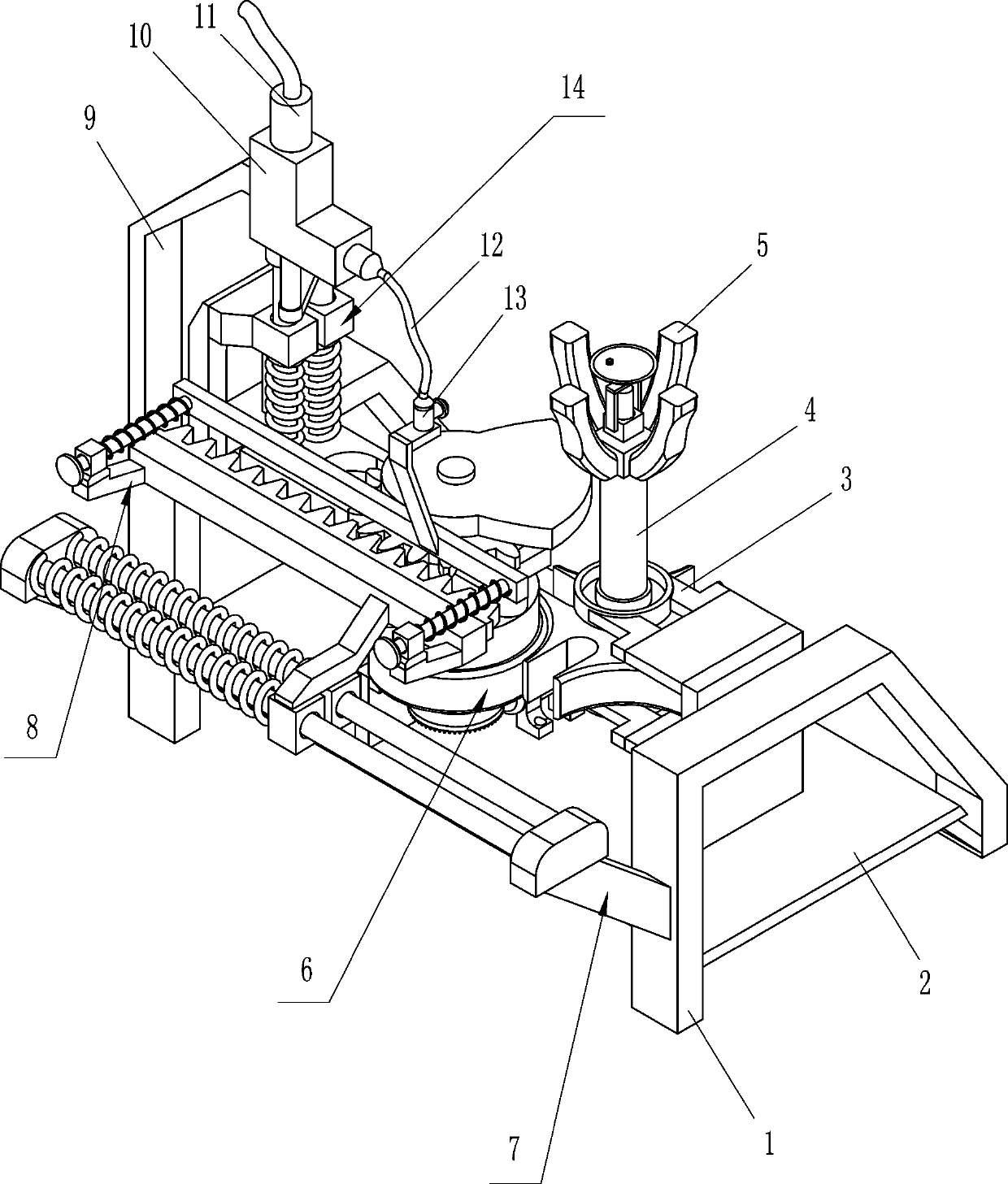

[0031] On the basis of Example 1, such as Figure 3-5 Shown:

[0032] The driving device 6 includes a second bearing seat 61, a second rotating rod 62, an arc-shaped disc 63, a driving rod 64, a driving motor 65, a gear transmission assembly 66 and a sheave 67, specifically:

[0033] A second bearing seat 61 is connected to the mounting plate 2, and the second bearing seat 61 is located at an angle of 45 degrees to the first bearing seat 3, and a second rotating rod 62 is connected inside the second bearing seat 61, so that An arc-shaped disk 63 is connected to the second rotating rod 62, and a driving rod 64 is connected to one side of the arc-shaped disk 63. A driving motor 65 is installed on the mounting plate 2, and the output shaft of the driving motor 65 is connected to the A gear transmission assembly 66 is connected between the lower sides of the second rotating rod 62 , and a sheave 67 is connected to the lower side of the first rotating rod 4 , and the arc edge of t...

Embodiment 3

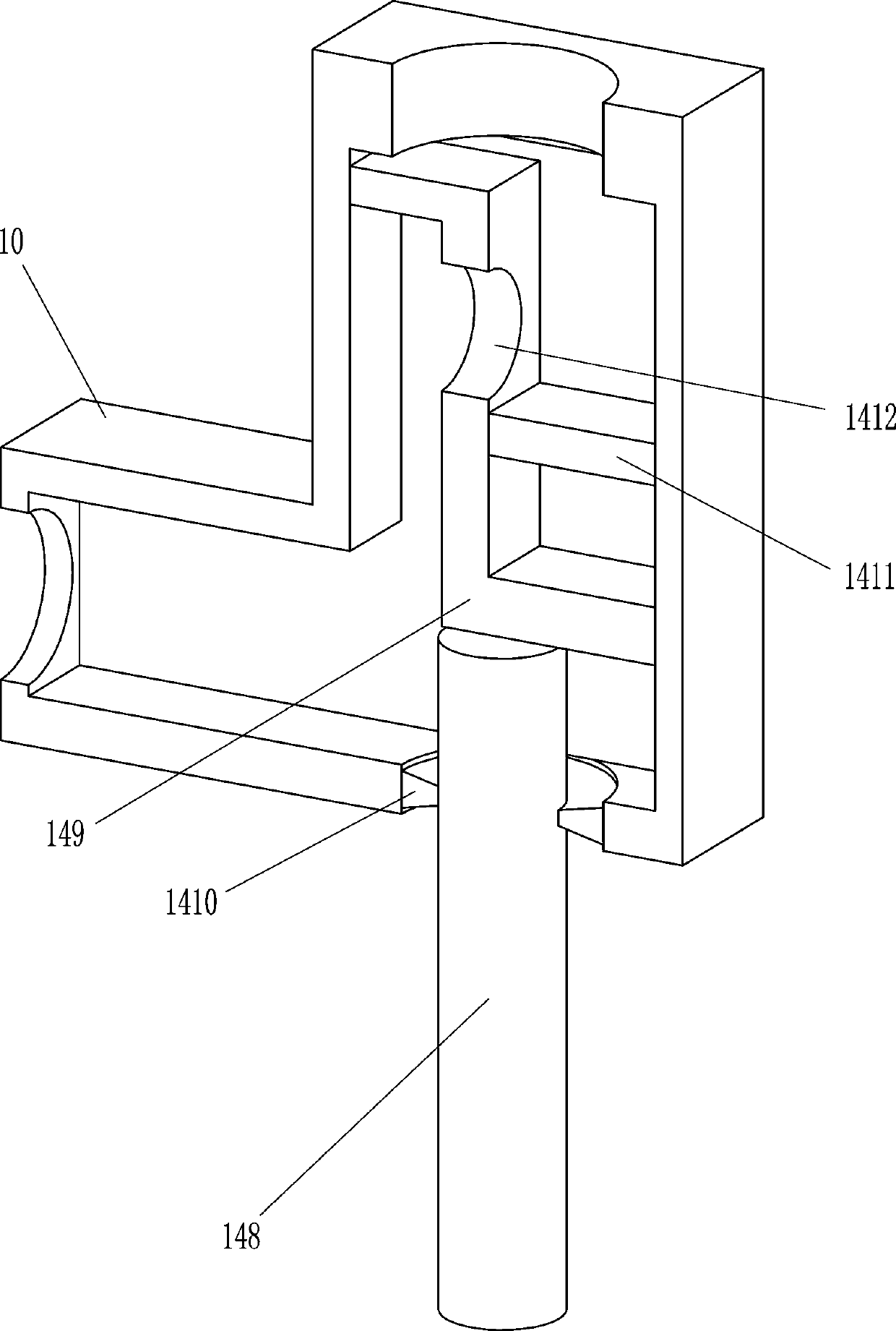

[0045] On the basis of Example 2, such as Figure 6-8 Shown:

[0046] It also includes a controlled gluing device 14, which includes a fixed frame 141, a third guide sleeve 142, a third guide rail 143, a third elastic member 144, a hollow frame 145, a ball 146, and an arc-shaped convex plate 147, lifting rod 148, moving plate 149, seal 1410 and baffle plate 1411, specifically:

[0047] A fixed frame 141 is connected to the upper side of the bracket 1 away from the side of the placement frame 5, and a third guide sleeve 142 is connected to the side of the fixed frame 141 near the placement frame 5, and a slide type is connected in the third guide sleeve 142. The third guide rail 143, the third elastic member 144 is connected to the lower side of the third guide sleeve 142, the lower side of the third elastic member 144 is connected to the lower side of the third guide rail 143, and the lower end of the third guide rail 143 is connected to There is a hollow frame 145, the holl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap