Double-head automatic valve insertion device of rotary disc type multi-canister separator

A separator and turntable technology, used in hand-held tools, manufacturing tools, etc., can solve the problems of uncontrollability, low production efficiency, high labor intensity, etc., to avoid stuck valves, improve production efficiency, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

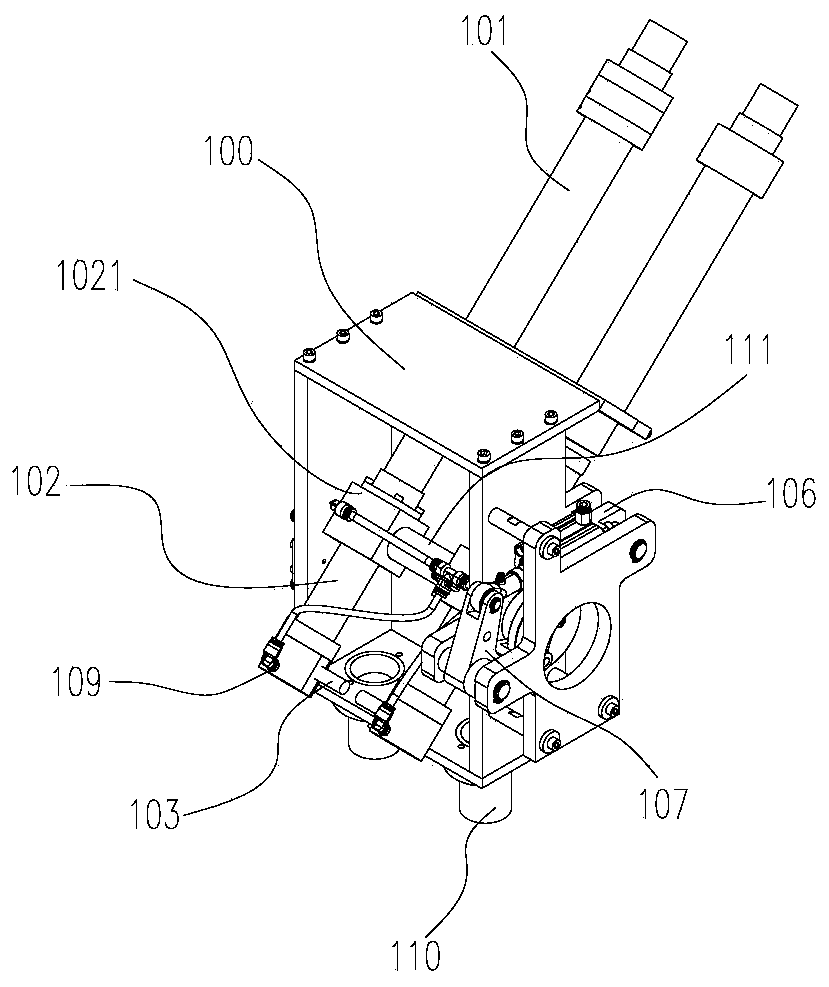

[0057] In order to enable those skilled in the art to better understand the solution of the present invention, the technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

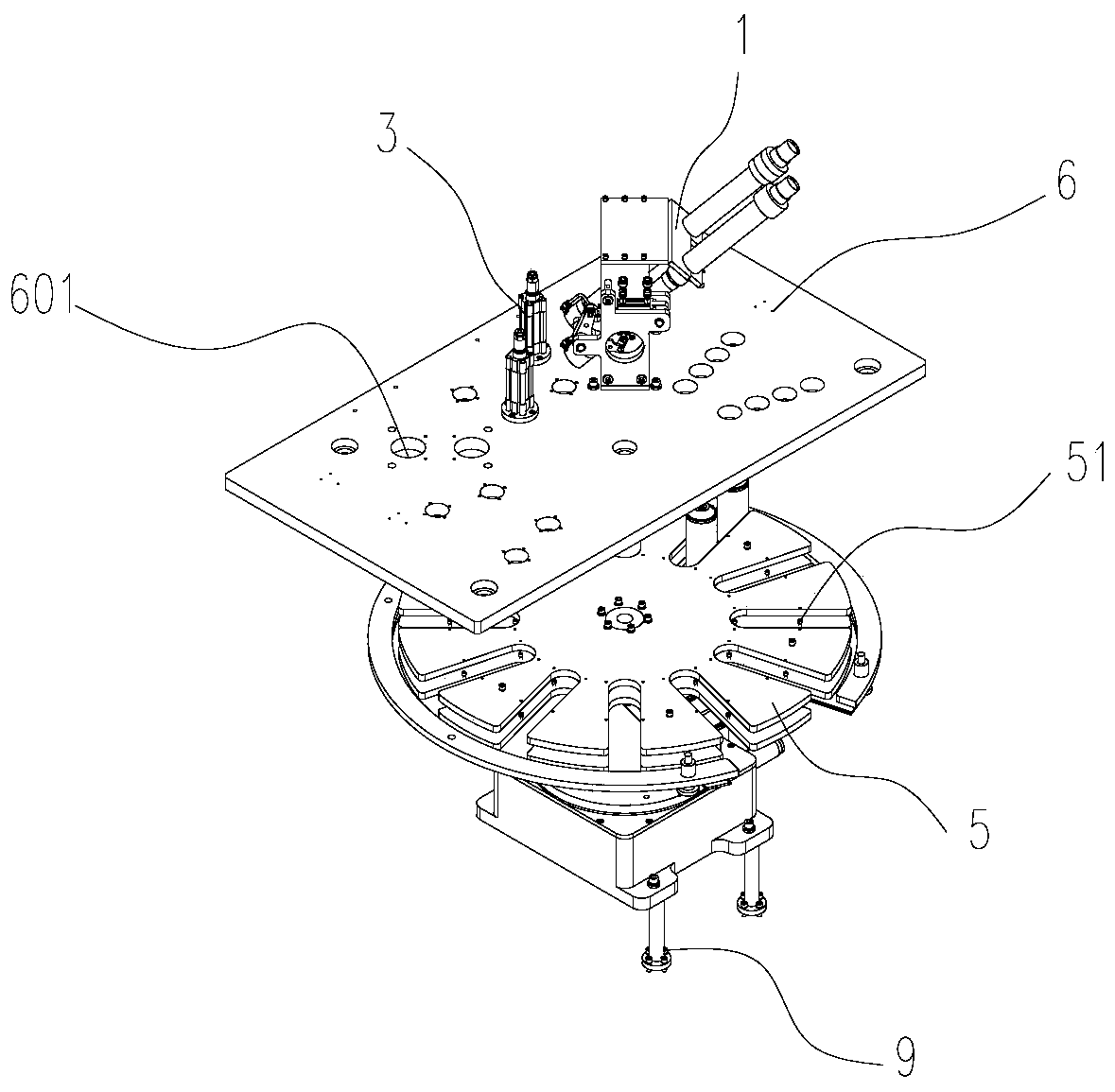

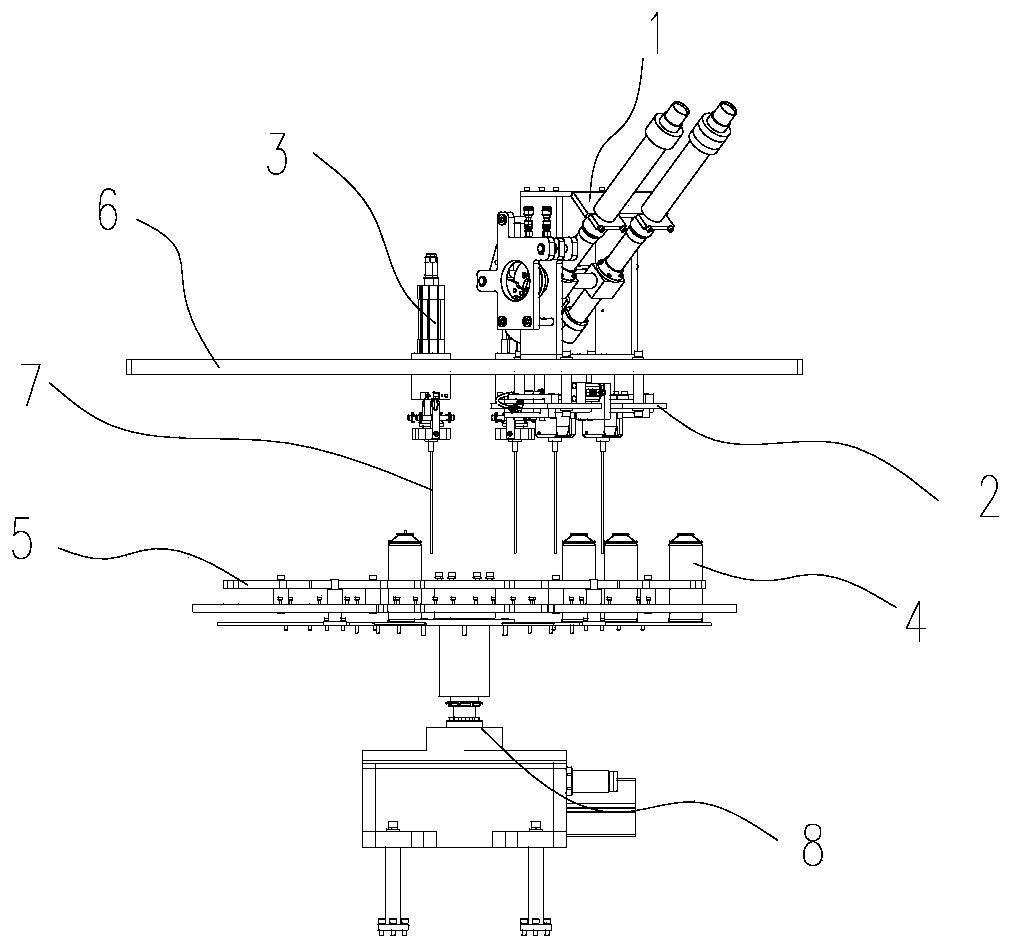

[0058] see Figure 1~2 (In order to clearly reflect the internal structure, figure 1 , 2 The workbench 6 and the components installed on it are separated from the lower turntable 5, and the actual positional relationship between the tank body 4 and the upper parts on the turntable 5 can be referred to Figure 14~21 ), a double-head automatic valve insertion device for a turntable multi-tank separator provided by the present invention includes a frame 9 on which a turntable 5 driven by a power device 8 is horizontally arranged, and the diameter of the circumference of the turntable 5 is According to the indexing rule in the direction ((grading rule: divide the circumferential angle into N degrees to achieve periodic indexing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com