Fluid end of vertical combination valve

A combination valve and hydraulic end technology, applied in the field of reciprocating pumps, can solve the problems of unreasonable front-end connection, affecting the force of the frame, and increasing the number of wearing parts of the pump valve. Influence and improve the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a fluid end of a vertical combined valve.

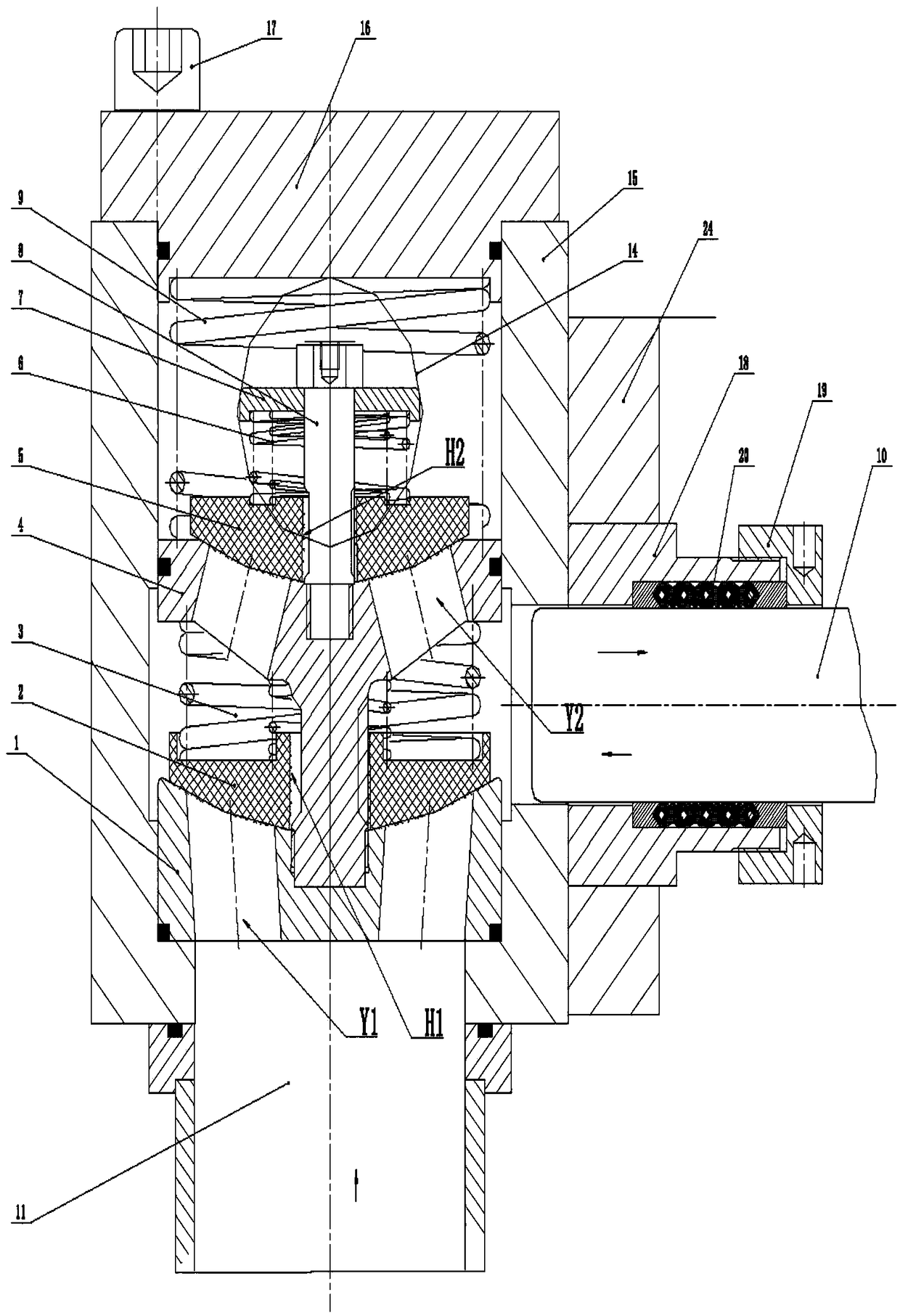

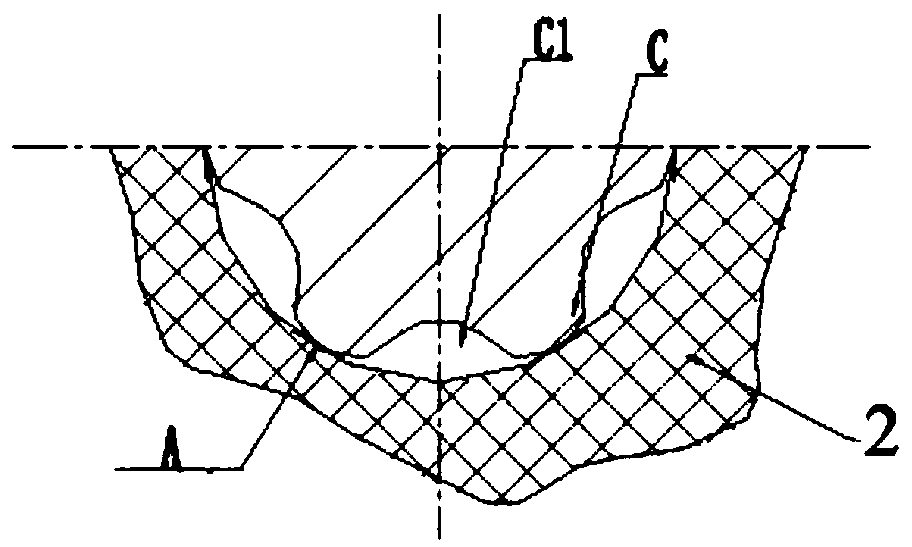

[0044] The hydraulic end of the vertical combination valve of the present invention consists of a suction valve seat 1, a suction valve plate 2, a suction spring 3, a discharge valve seat 4, a discharge valve plate 5, a discharge spring 6, a discharge valve spring seat 7, and a discharge valve plate guide rod 8 , Compression spring 9, valve gland 16, pump body 15, stuffing box 18, plunger 10, plunger seal 20, adjustment nut 19 components. The suction valve seat hole Y1 and the discharge valve seat hole Y2 are not on the same circumferential section; the discharge valve seat 4 is provided with a guide rod part that guides the suction valve plate 2, and the suction valve plate 2 is formed by the guide rod part on the discharge valve seat 4. Guided, the guide rod portion on the suction valve plate 2 and the discharge valve seat 4 and the discharge valve plate 5 and the discharge valve guide rod 8 are alwa...

Embodiment 2

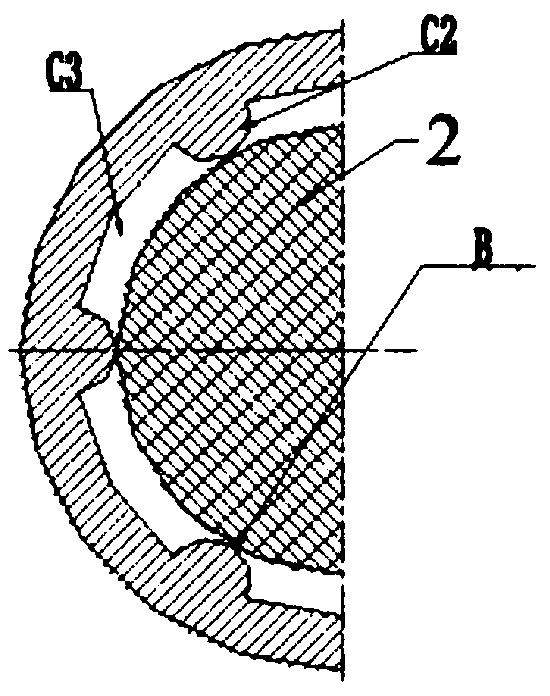

[0052] Such as Figure 4 Shown is another embodiment of the hydraulic end vertical combination valve part of the vertical combination valve of the present invention, which is figure 1 Another deformation structure of the discharge valve seat, that is, the figure 1 The guide rod at the bottom of the discharge valve seat 4 becomes the guide cylinder at the bottom of the discharge valve seat 4, and the guide of the suction valve plate 2 changes from the inner arc hole H1 to the outer arc H2. The guide cylinder at the lower part of the discharge valve seat 4 is connected with the suction valve seat 1, there is an arc H2 on the outer circle of the suction valve plate 2, and there are several inner holes of the guide cylinder at the lower part of the discharge valve seat 4 guided by the arc H12 of the suction valve plate 2 Small arc C2 and groove C3, such as image 3 As shown, there are several contact points B on the contact section to ensure that when the suction valve plate 2 m...

Embodiment 3

[0054] Such as Figure 5 Shown is another embodiment of the hydraulic end vertical combined valve part of the vertical combined valve of the present invention, the discharge valve seat 4 and the suction valve seat 1 are integrally arranged valve seats 12, and the lower part is matched with the suction valve plate 2 The sealing surface has the suction valve seat hole Y1, the upper part is the sealing surface matched with the discharge valve plate 5, and has the discharge valve seat hole Y2, the middle part of the cylinder is used to guide the suction valve plate 2, and the structure of the guide part is the figure 1 are basically the same. The discharge valve plate 5 and the discharge valve spring 6 are placed inside the discharge valve cover 13, the outer circle of the discharge valve plate 5 and the guide of the discharge valve cover 13 Figure 4 The guide structure of the suction valve plate 2 and the lower part of the discharge valve seat 4 is basically the same, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com