Food packaging method and equipment

A technology for food packaging and packaging methods, which is applied in the directions of packaging, packaging food, transportation and packaging, etc., can solve the problems of food bag blocking, single function, food bags cannot be well sealed, etc., and achieve the effect of preventing material blocking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

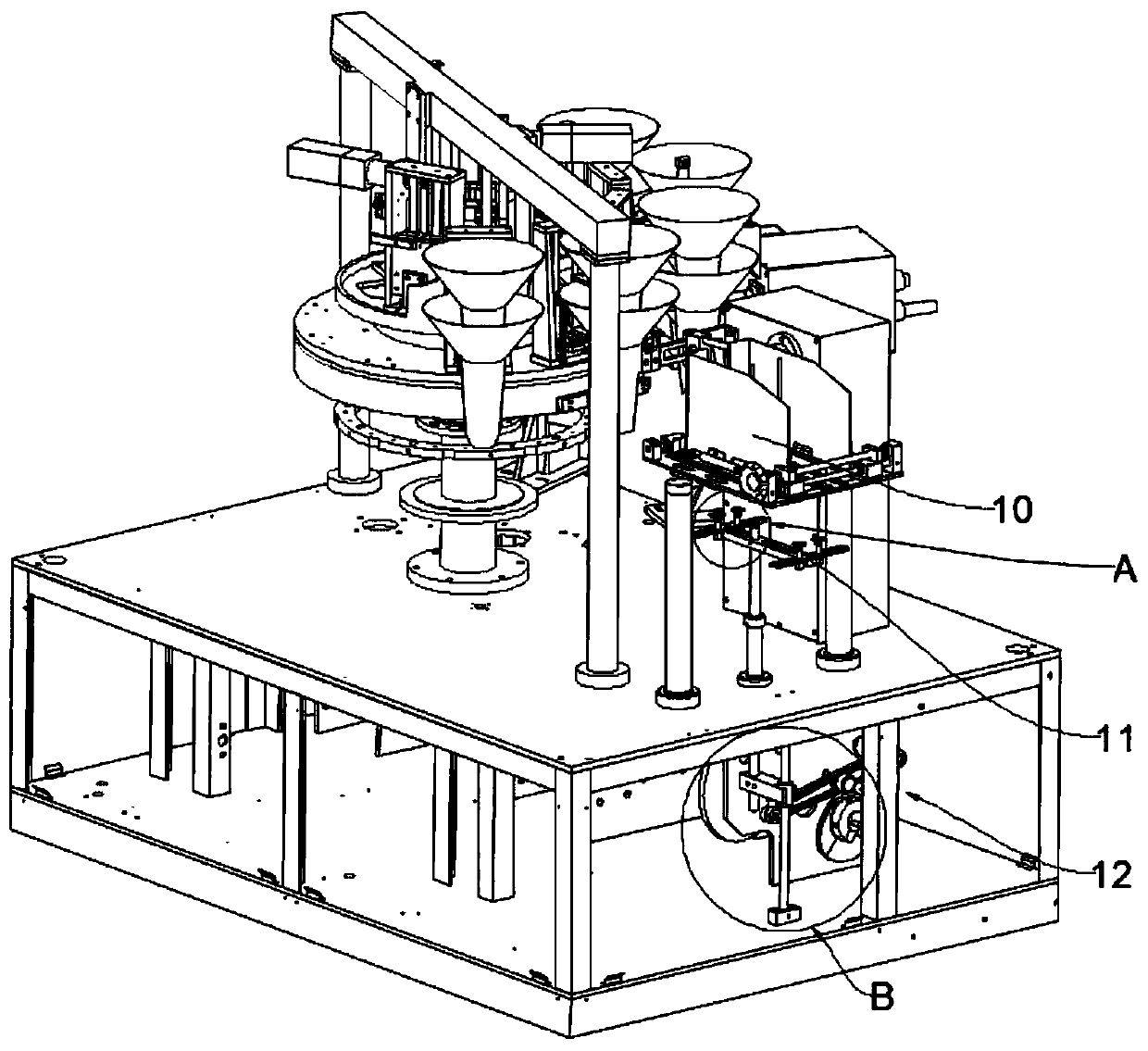

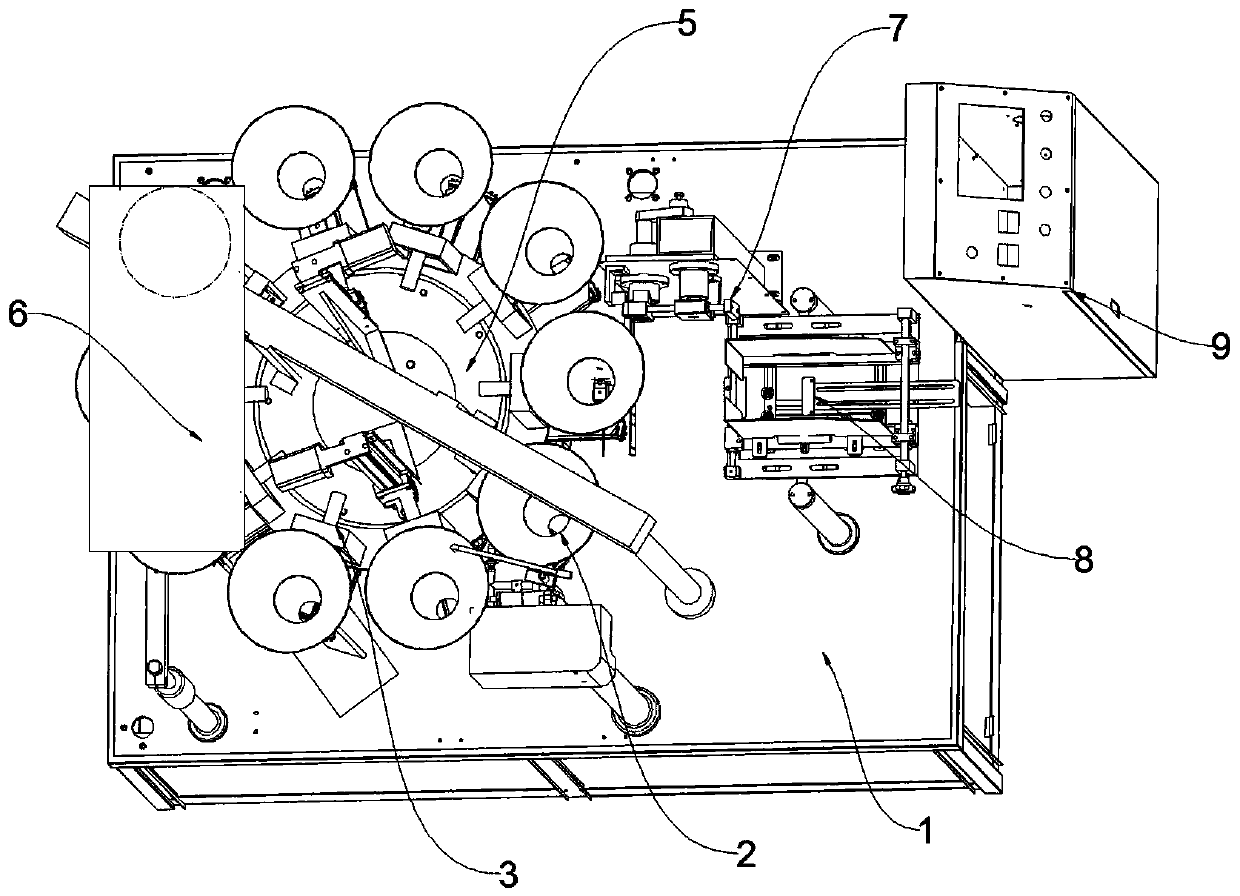

[0038] The invention discloses a food packaging method, such as Figure 1 to Figure 9 As shown, the packaging method steps include:

[0039] Unloading: the packaging bag is clamped by the clamp, and the packaging bag is loaded through the funnel of the unloading station 7;

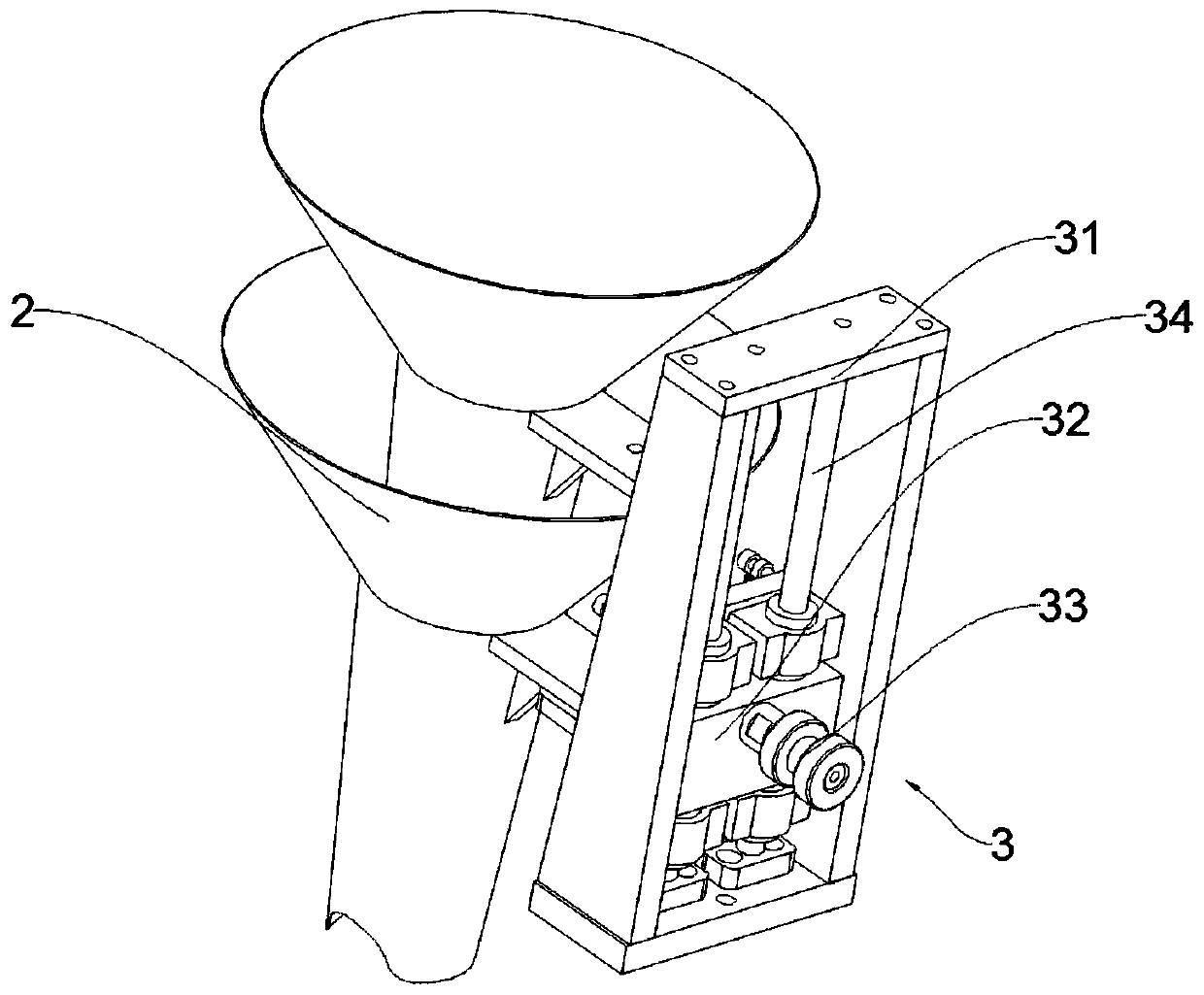

[0040] Stirring material: Stirring material is carried out to the packing bag of filling through material-stirring mechanism 6, and material-stirring mechanism 6 comprises frame body 61, telescopic rod 62 and material head 63, and frame body 60 is fixedly installed telescopic rod 62, and telescopic rod 62 drives to poke The material head 63 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com