Feeding device for silicon wafer processing

A silicon wafer and mounting port technology is applied in the field of feeding devices for silicon wafer processing, which can solve the problems of silicon wafer breakage and hard extrusion, and avoid hard extrusion, structural damage, and excessive initial contact force. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

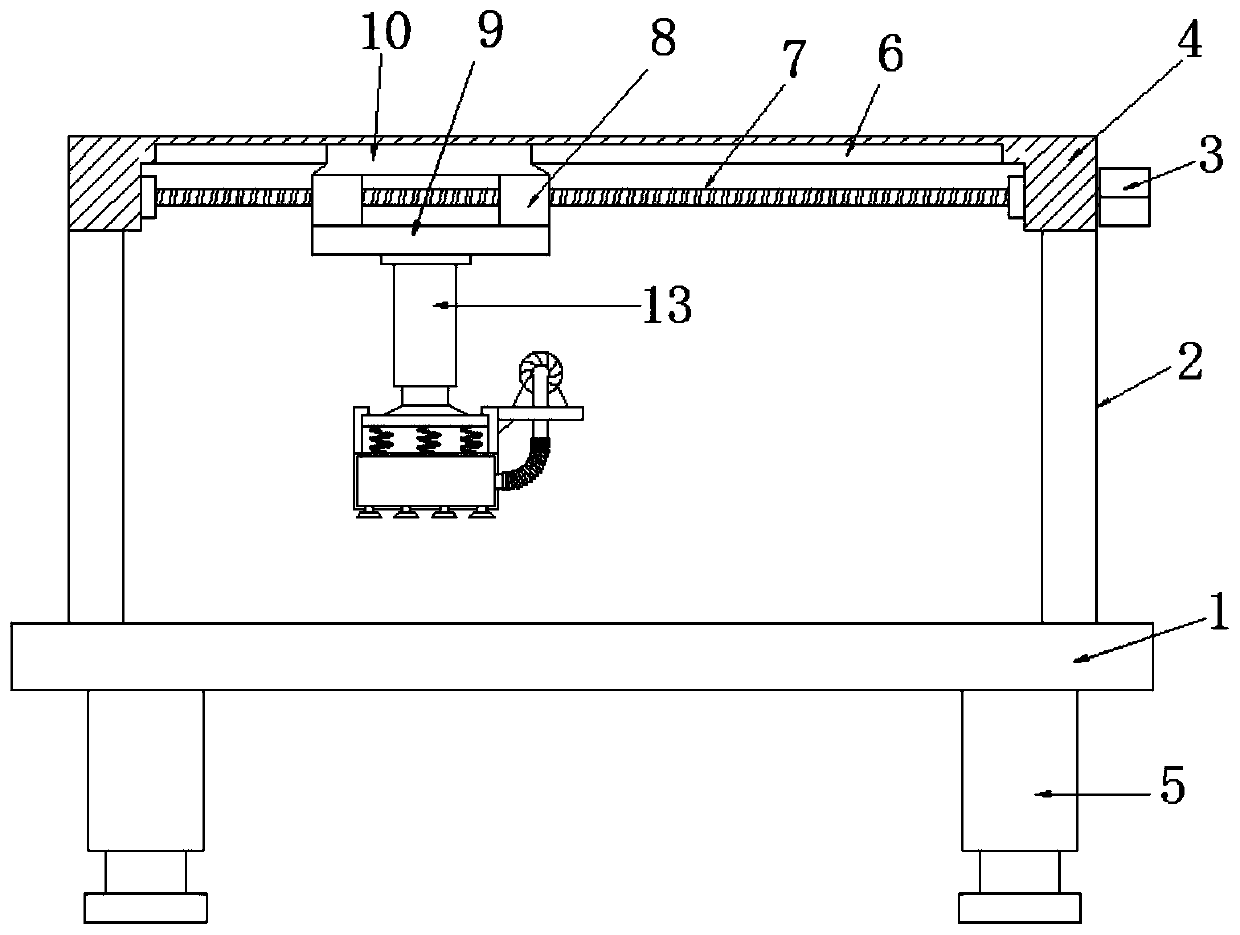

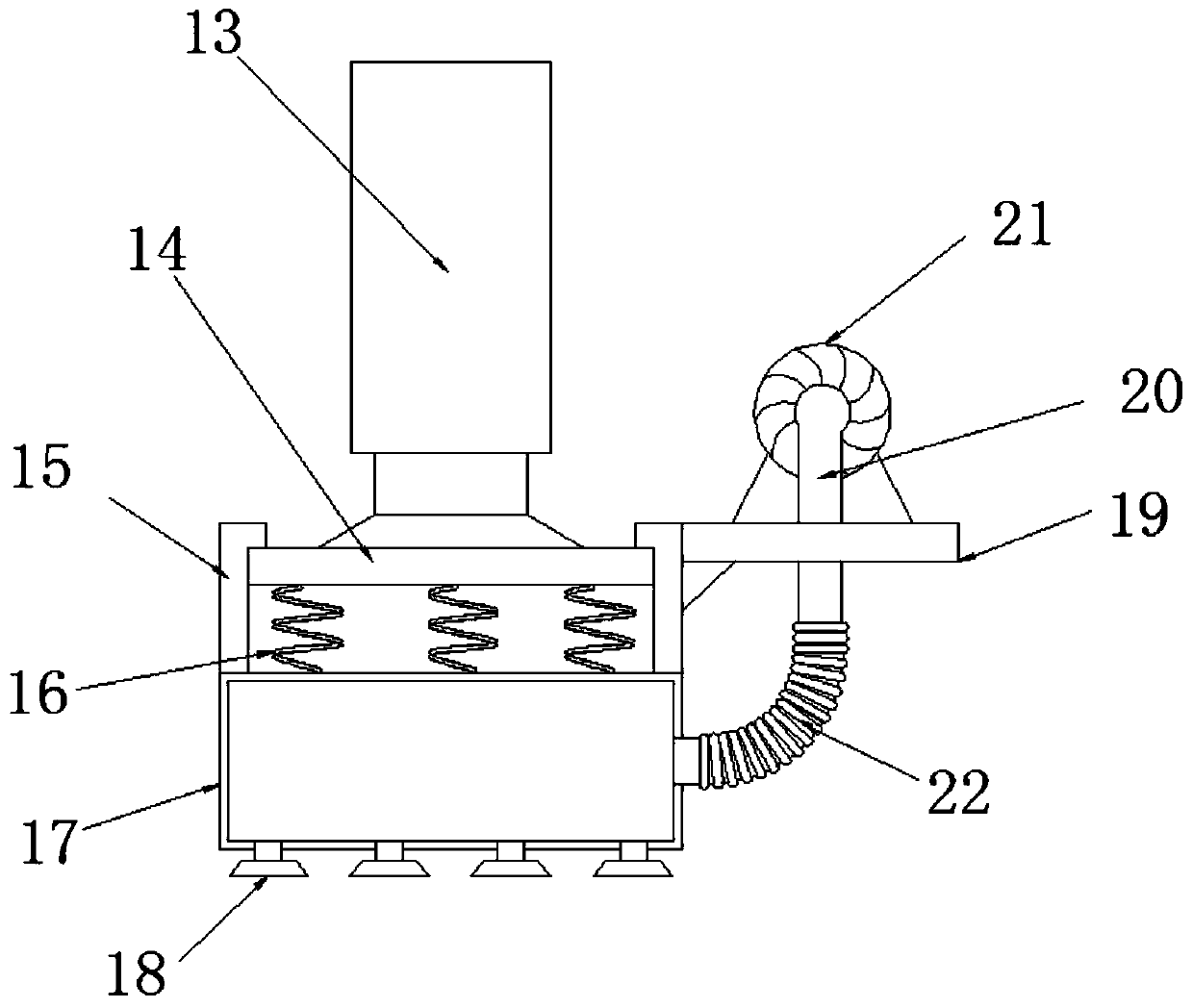

[0024] refer to figure 1 and figure 2 , a feeding device for silicon wafer processing, including a base 1, support rods 2 are fixed on both sides of the top outer wall of the base 1, and the same top plate 4 is fixed on the top of the two support rods 2, and the bottom outer wall of the top plate 4 is opened There is an installation port, and the same screw rod 7 is installed on the inner wall on both sides of the installation port. One end of the screw rod 7 is connected to the driving mechanism. Sliders 8 are fixed on both sides of the bottom outer wall of the guide block 10, and the two sliders 8 are threadedly socketed on the screw rod 7, and the bottom of the two sliders 8 is fixed with the same connecting plate 9, and the bottom outer wall of the connecting plate 9 is fixed with a telescopic rod 13, and the bottom end of the extension rod of the telescopic rod 13 is fixed with a fixed plate 14, the bottom of the fixed plate 14 is fixed with an adsorption mechanism, and...

Embodiment 2

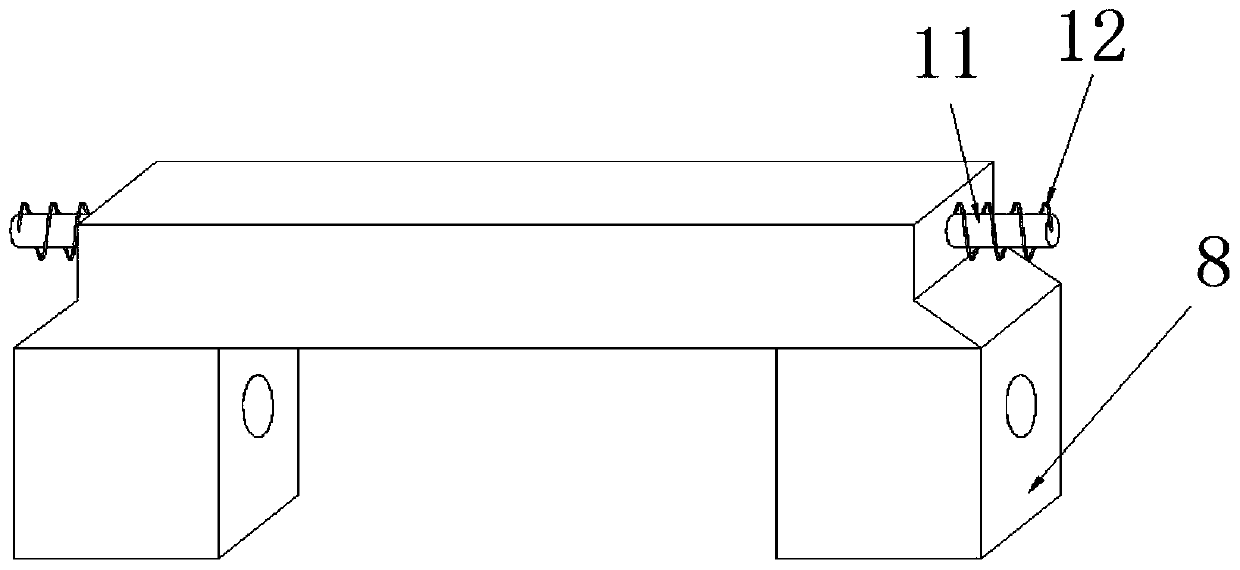

[0028] refer to image 3 , a feeding device for silicon wafer processing. The difference between this embodiment and Embodiment 1 is that the outer walls of both ends of the guide block 10 are also fixed with plug posts 11, and the plug posts 11 are sleeved with buffer springs 12. 1. One end of the buffer spring 12 is fixedly connected with the guide block 10, and the inner walls of the opposite sides of the guide groove 6 are provided with inserting column grooves matching the specification of the inserting column 11.

[0029] The working principle of this embodiment: the insertion column 11 can move laterally synchronously with the guide block 10, when the guide block 10 moves to both ends of the guide groove 6, the insertion column 11 is inserted into the insertion column groove, and the buffer spring 12 gradually Compressed, the reaction force of the buffer spring 12 can protect and buffer the guide block 10, avoiding the hard extrusion of the guide block 10 and the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com