A kind of high temperature resistant aluminum oxide nanocrystalline airgel material and preparation method thereof

A kind of aluminum oxide nano and airgel technology, applied in chemical instruments and methods, aluminum compounds, inorganic chemistry, etc., can solve the problems of hole reduction, heat insulation failure, application limitation, etc., and achieve sufficient coating process and good temperature resistance Sex, the effect of small shrinkage

Active Publication Date: 2022-05-31

AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Carbon aerogels and ceramic aerogels have good high temperature resistance, but there are certain limitations in their application, that is, thermal insulation applications above 1400 °C can only be achieved in an oxygen-free environment, while carbon aerogels and ceramic aerogels There is no effective way to overcome the antioxidant

Oxide aerogels such as silica, alumina, and zirconia will undergo severe crystal transformation and sintering at high temperatures, leading to structural collapse, resulting in the growth of nanoparticles and the reduction of pores, so that the specific surface area of the aerogel will decrease sharply. decline, greatly weakening its thermal insulation performance and failure of thermal insulation

Aiming at the limitations of oxide aerogels, related studies have carried out modification processes such as rare earth metal oxides or multi-component doping, but their effects are limited

[0004] Chinese patent application CN201810068117.1 discloses a method for preparing high-temperature-resistant airgel materials, although the airgel prepared by this method has good high-temperature resistance characteristics, and the heat-resistant temperature is above 1000°C, and can even withstand above 1300°C High temperature, but the airgel material will still produce a series of phase transitions at high temperatures above 1200 °C, making its specific surface area after high temperature heat treatment at 1400 °C small, no more than 10m 2 / g, so the high temperature insulation performance of the airgel material is not very good

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

preparation example Construction

[0050] According to some preferred embodiments, in step (4), the condition for freezing is to freeze 2h under liquid nitrogen. in this

Embodiment 1

Embodiment 2

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Login to View More

Abstract

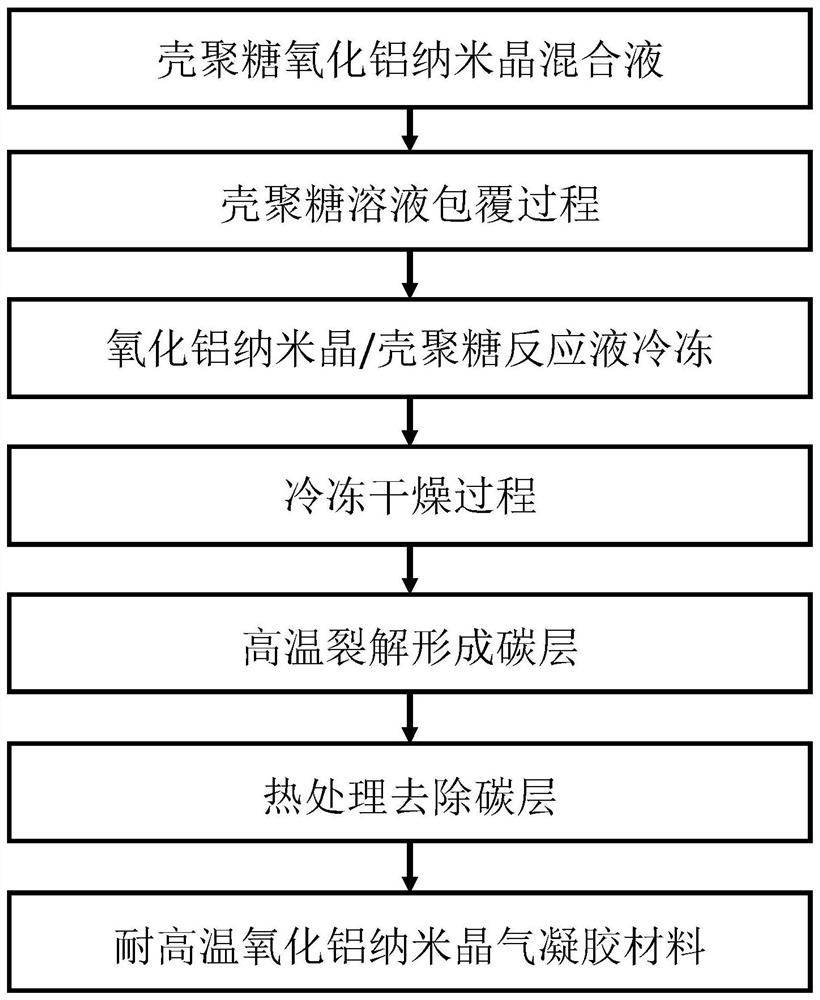

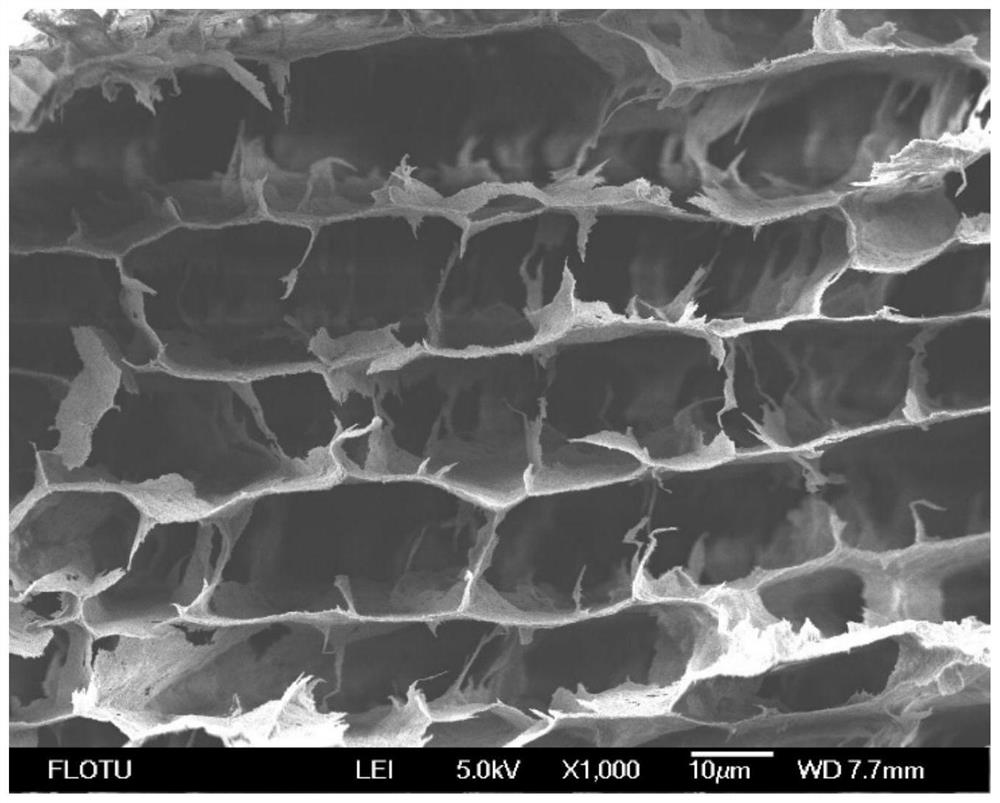

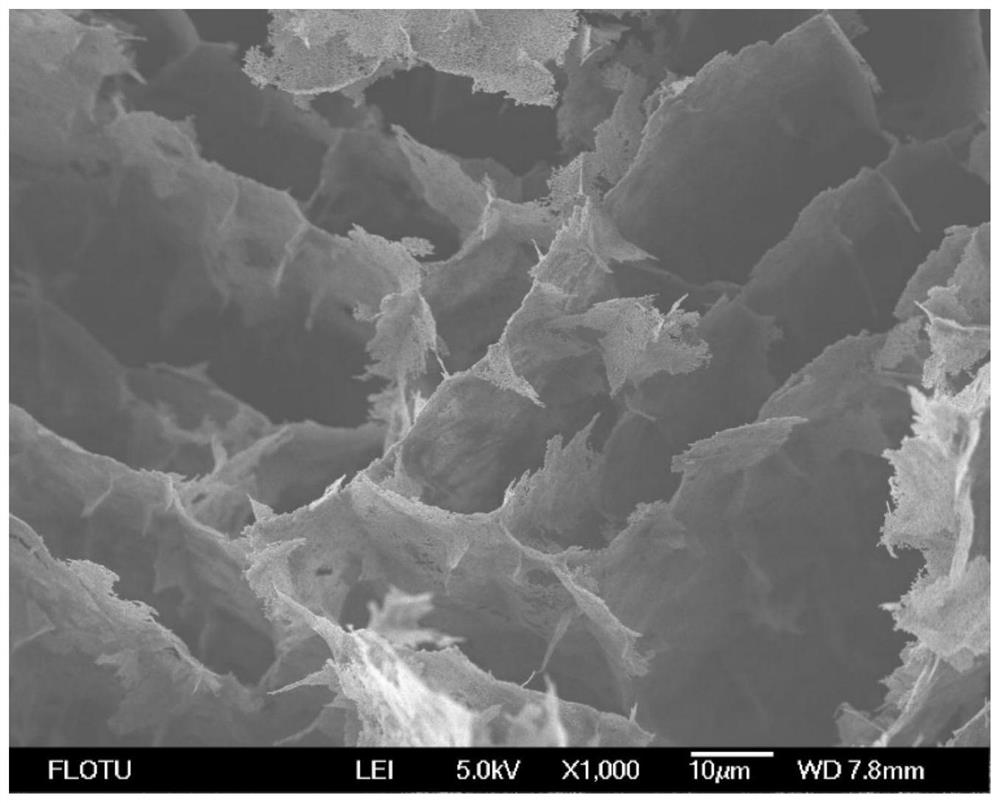

The invention relates to a high-temperature resistant aluminum oxide nanocrystalline airgel material and a preparation method thereof. The method is as follows: uniformly mix aluminum oxide nanocrystals and chitosan solution to obtain a mixed solution, add glacial acetic acid to dissolve chitosan, and then heat at 60-100°C for 4-8 hours to obtain alumina nanocrystal chitosan Dispersion liquid; the dispersion liquid is subjected to a vacuum pumping process to obtain an alumina nanocrystal / chitosan reaction liquid; the reaction liquid is frozen and freeze-dried, and then subjected to high-temperature cracking to obtain an alumina / carbon composite airgel ; The alumina / carbon composite airgel is heat-treated in an air atmosphere to prepare a high-temperature-resistant alumina nanocrystalline airgel material. The invention obtains alumina / carbon composite airgel through pyrolysis at high temperature. Since the carbon coating layer can fix the nanoparticles and play a certain role in isolation, the sintering of the material is prevented, and the material transitions to the airgel without sintering. The stable crystal form realizes the preparation of high temperature resistant alumina airgel.

Description

A kind of high temperature resistant alumina nanocrystalline aerogel material and preparation method thereof technical field The present invention relates to aerogel preparation technical field, relate in particular to a kind of high temperature resistant alumina nanocrystalline aerogel material and its preparation method. Background technique Aerogel material is a kind of gel material whose dispersion medium is gas, which is composed of colloidal particles or polymer molecules. A nanoporous solid material with a network structure composed of aggregates, the size of the pores in the material is in the order of nanometers. class. Its porosity is as high as 80~99.8%, the typical size of pores is 1~100nm, and the specific surface area is 200~1000m 2 / g, while Densities as low as 3kg / m 3 , the room temperature thermal conductivity can be as low as 0.012W / m·k. It is precisely because of these characteristics that aerogel materials are It has broad application ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C01F7/021

CPCC01F7/021C01P2006/32C01P2006/90Y02A30/24

Inventor 张恩爽雷朝帅李健黄红岩李文静张凡

Owner AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com