Acid pickling device of motor rotor silicon steel sheet

A technology of pickling device and motor rotor, applied in the field of pickling, can solve problems such as low pickling efficiency, and achieve the effects of improving pickling efficiency, improving the degree of turbulence and realizing flushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

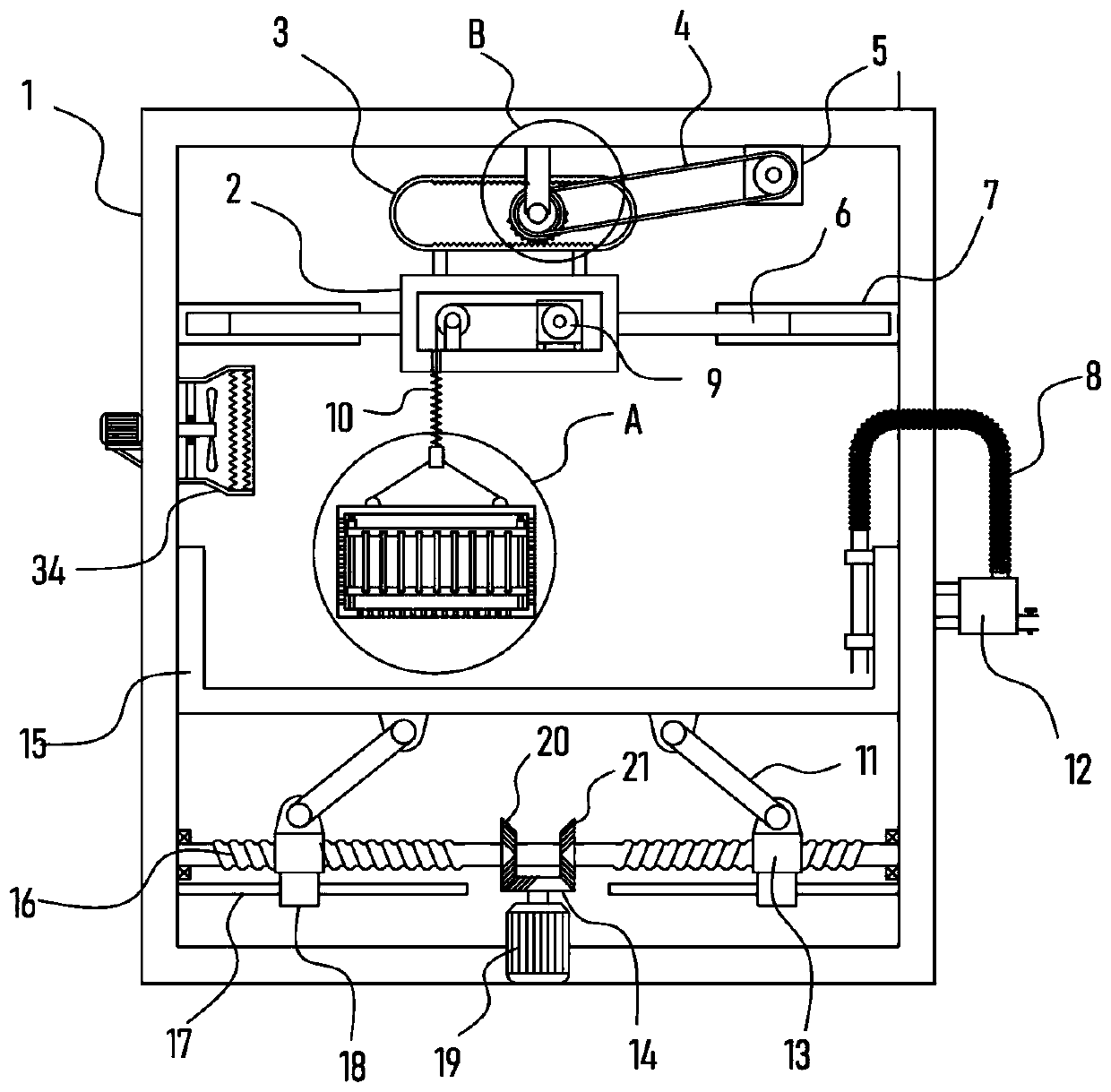

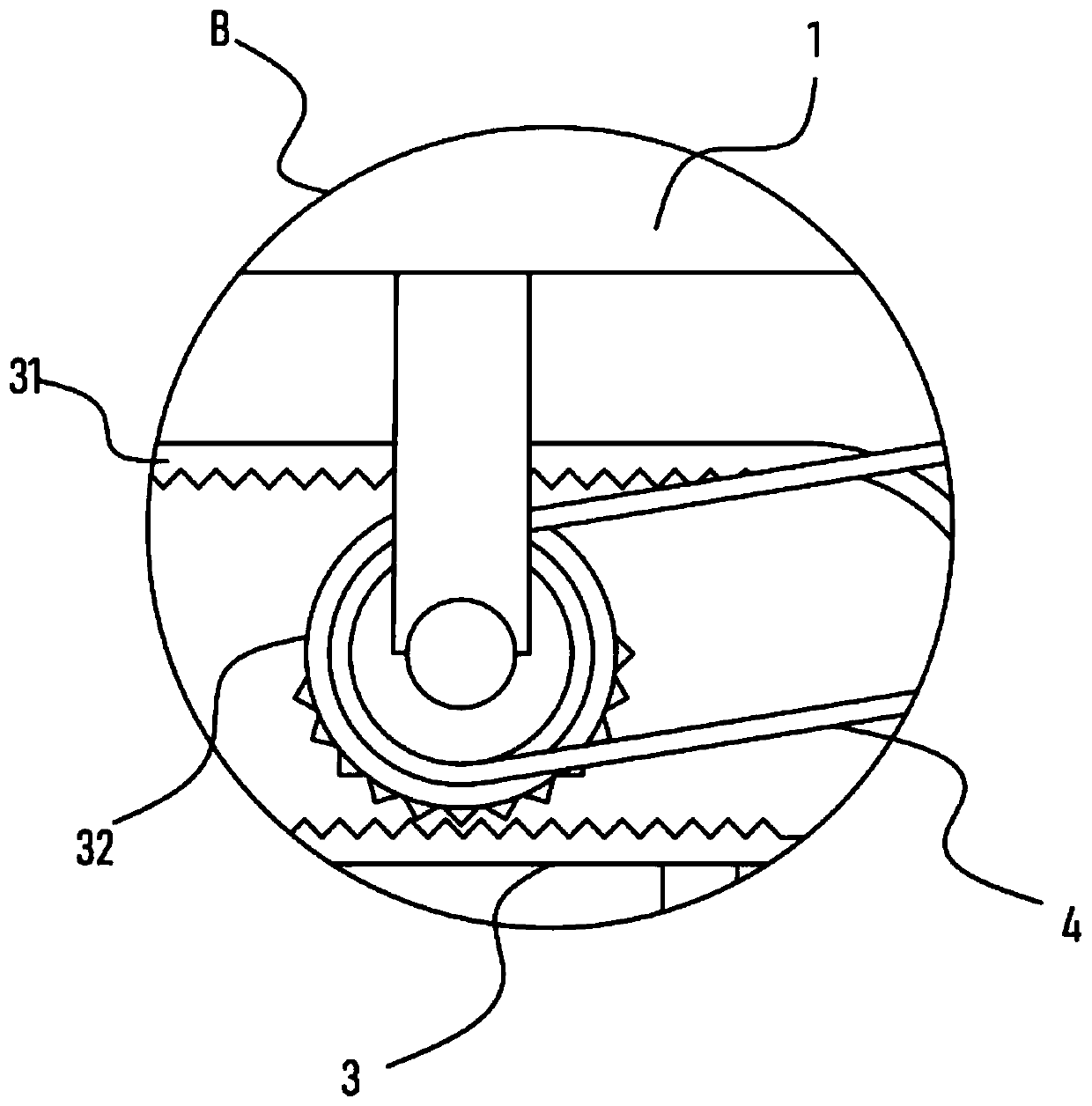

[0025] see Figure 1-4 , a pickling device for a motor rotor silicon steel sheet, comprising a fixed frame 1, a motor III19 is fixedly installed in the fixed frame 1, a reciprocating lifting mechanism is connected to the motor III19, and a pickling device for storing pickling liquid is connected to the reciprocating lifting mechanism. Groove 15, the lifting box 2 is installed on the fixed frame 1, the bottom of the lifting box 2 is connected with a mesh basket 24 for loading silicon steel sheets, and the vertical adjustment for adjusting the vertical height of the mesh basket 24 is provided in the lifting box 2 mechanism, the inside of the basket 24 is provided with a locking mechanism for fixing the silicon steel sheet, the motor I5 is fixed on the fixed frame 1, and the output shaft of the fixed frame 1 is driven and connected with a reciprocating translation mechanism for driving the lifting box 2 to move laterally .

[0026] When carrying out the pickling operation of the...

Embodiment 2

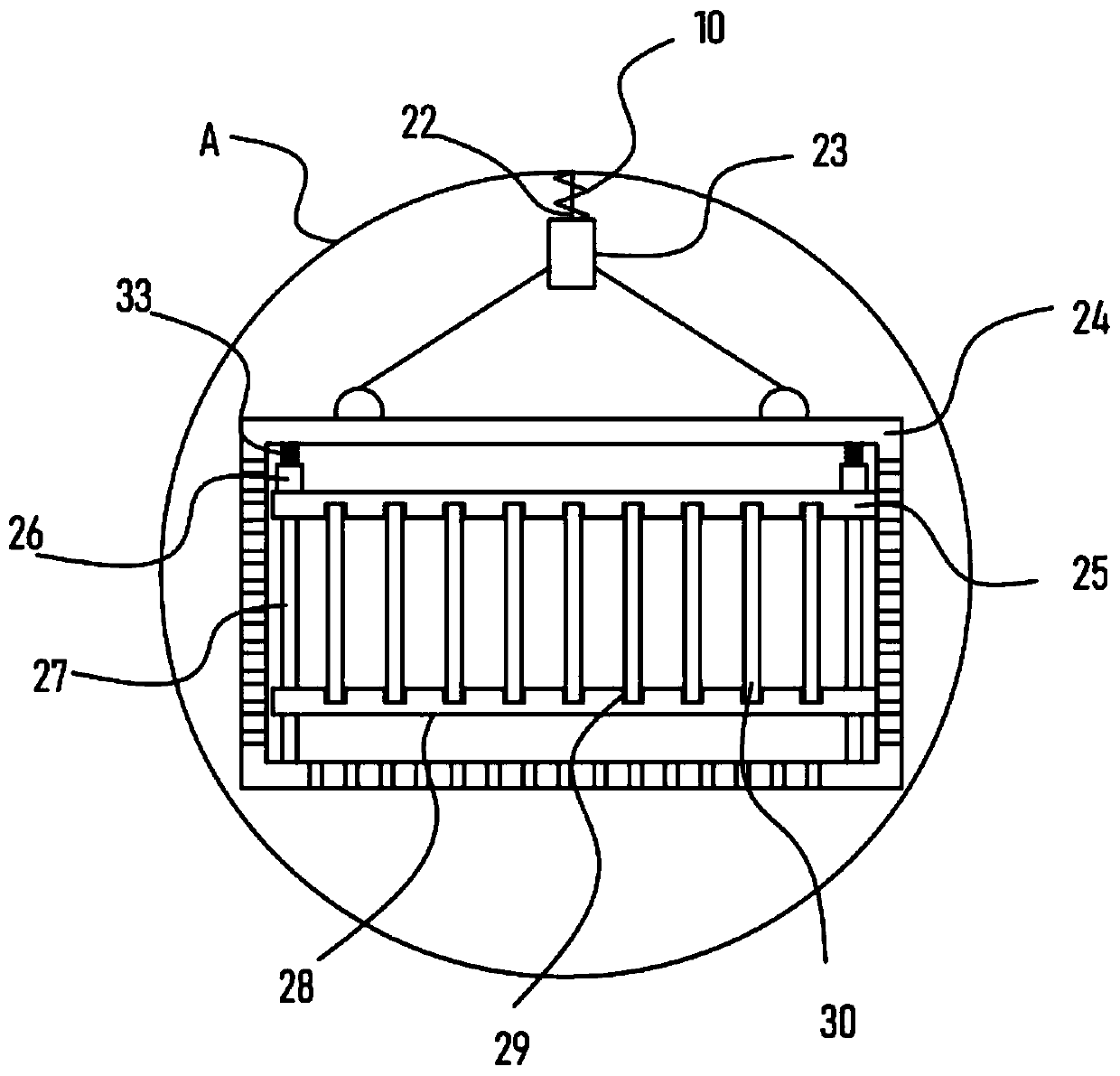

[0032] On the basis of Embodiment 1, in addition, the device is also provided with a vertical adjustment mechanism, which includes a motor II9 fixed in the lifting box 2, and a winding wheel is driven and connected to the motor II9, and a pulley is wound on the winding wheel. Rope 22, the lower end of stay rope 22 is provided with the connection piece 23 that is fixed with mesh basket 24, is fixed with spring coil 10 between connection piece 23 and lifting box 2, and the hot air blower 14 that horizontal setting is fixed on described pickling tank 15 side tops .

[0033] The motor II9 can drive the winding wheel to rotate, and the winding wheel winds or unwinds the stay rope 22. The stay rope 22 can drive the net basket 24 to lift vertically through the connecting block 23, so as to realize the vertical height of the silicon steel sheet in the net basket 24. Adjustment, after the pickling of the silicon steel sheet is finished, the height of the mesh basket 24 is promoted to r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com