Vertical connecting node for fabricated building edge module and using method thereof

A node-connecting and prefabricated technology, applied in the direction of architecture and building structure, can solve the problems of less connection forms of modular combined houses, high integration of modular houses, affecting the application scope of nodes, etc., so as to improve operation efficiency and installation. The effect of high quality, mechanical properties and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

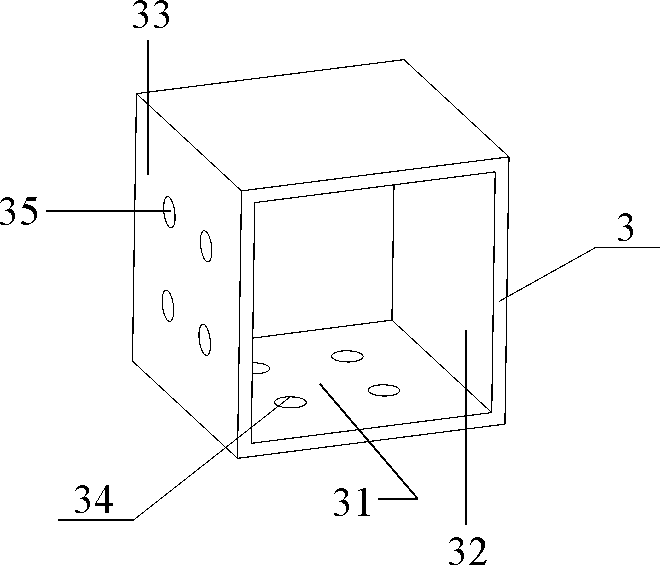

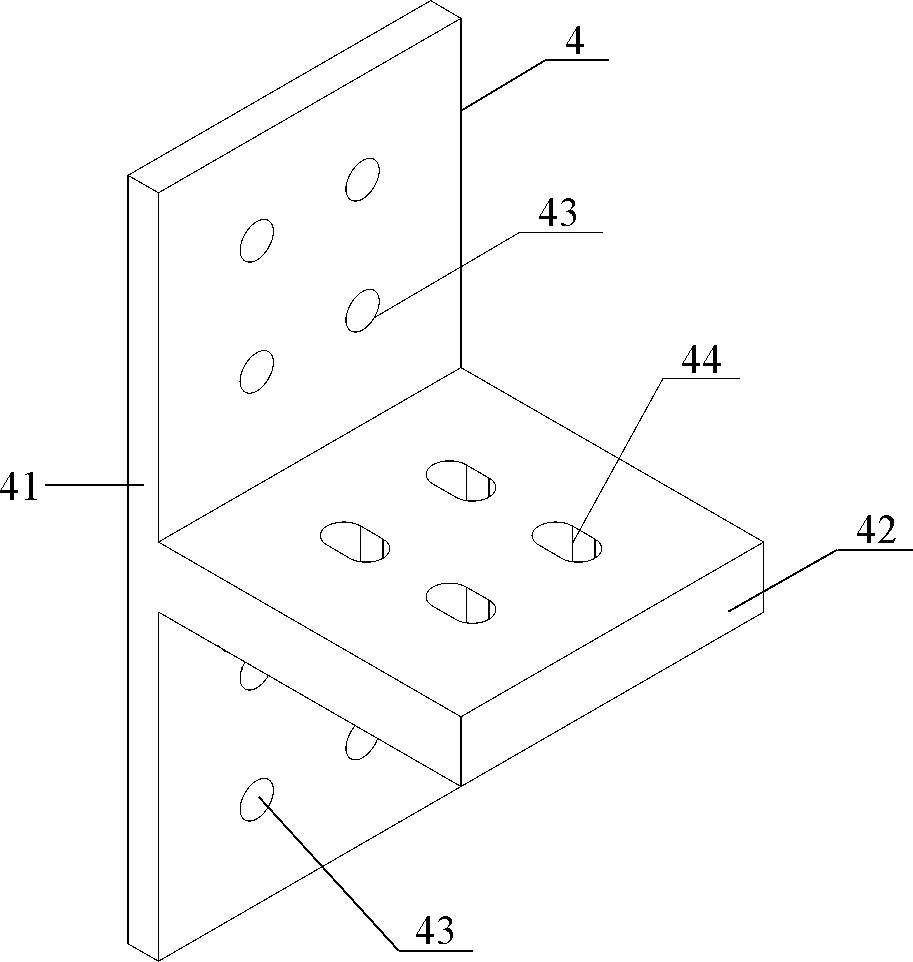

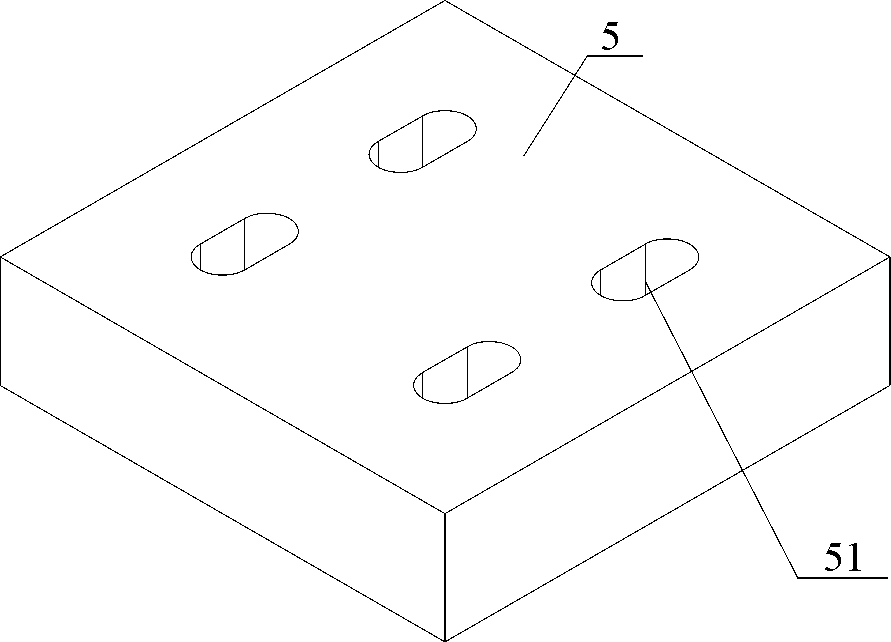

[0029] A vertical connection node for a prefabricated building side module, including a column 1, a beam 2, a connecting corner piece 3, a T-shaped connecting piece 4, a backing plate 5 and a diagonal bracing plate 6, such as Figure 1 to Figure 6 As shown, the specific structure is:

[0030] The column 1, the beam 2 and the connecting corner fitting 3 are all hollow pipe fittings with a rectangular cross-section;

[0031] One outer wall of the beam 2 is used as the beam connecting surface 21, the two outer walls adjacent to the beam connecting surface 21 are used as the beam working surface 22, and the outer walls opposite to the beam connecting surface 21, that is, adjacent to the two beam working surfaces 22 are used as The beam support surface 23 and the beam working surface 22 are provided with mutually facing beam working holes 24, and the beam connecting surface 21 between the two beam working holes 24 is provided with a beam connecting hole 25, and the beam connecting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com