A prefabricated unit-based prefabricated house and its construction method

A prefabricated and housing technology, applied in residential construction, architecture, building structure, etc., can solve problems such as weak connection, increase component cost, affect construction progress, etc., to ensure stability and strength, enhance stability and Strength, the effect of ensuring construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

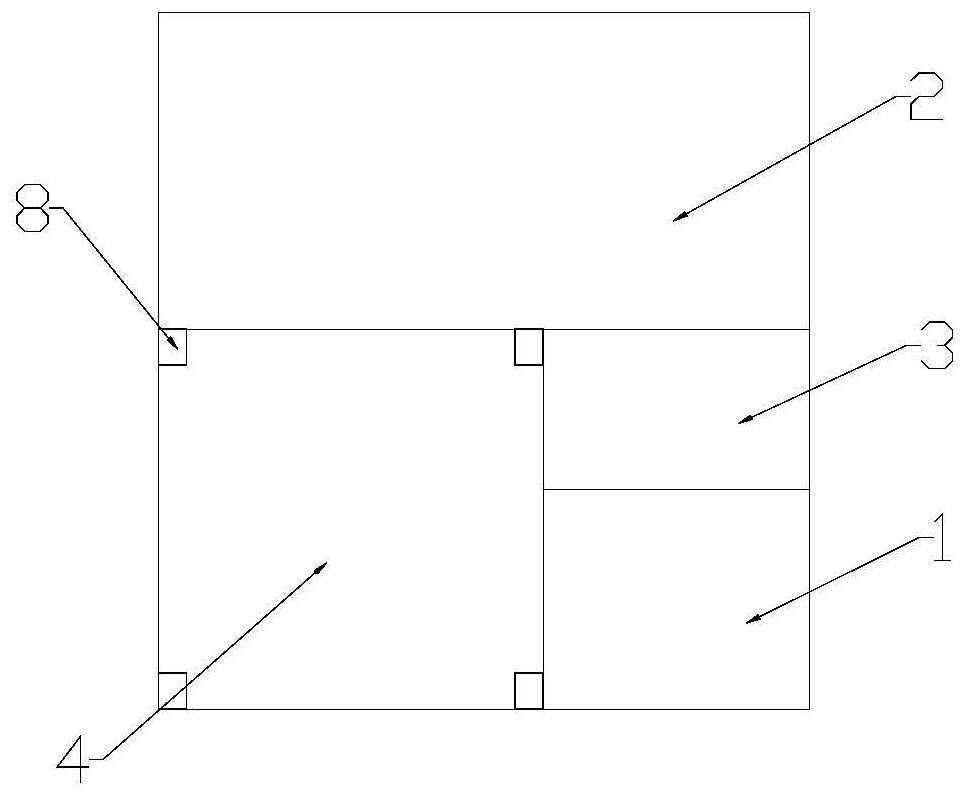

[0044] like figure 1 As shown, a prefabricated house based on prefabricated units includes kitchen 1, bedroom 2, bathroom 3 and living room 4. The kitchen 1, bedroom 2 and bathroom 3 all adopt prefabricated housing units, and the prefabricated housing units include prefabricated concrete Frame, the precast concrete frame includes a plurality of vertical precast concrete columns 5, the upper ends between adjacent precast concrete columns 5 are provided with horizontal precast concrete beams 6, the upper ends of the precast concrete beams 6 are provided with precast concrete floors 7, the precast concrete floors The 7th is provided with a stairway as required. The living room 4 includes a plurality of vertical positioning concrete columns 8 , and positioning concrete beams are arranged between the upper ends of the adjacent positioning concrete columns 8 .

[0045] The use method of this embodiment: the living room 4 usually has different requirements according to the area of ...

Embodiment 2

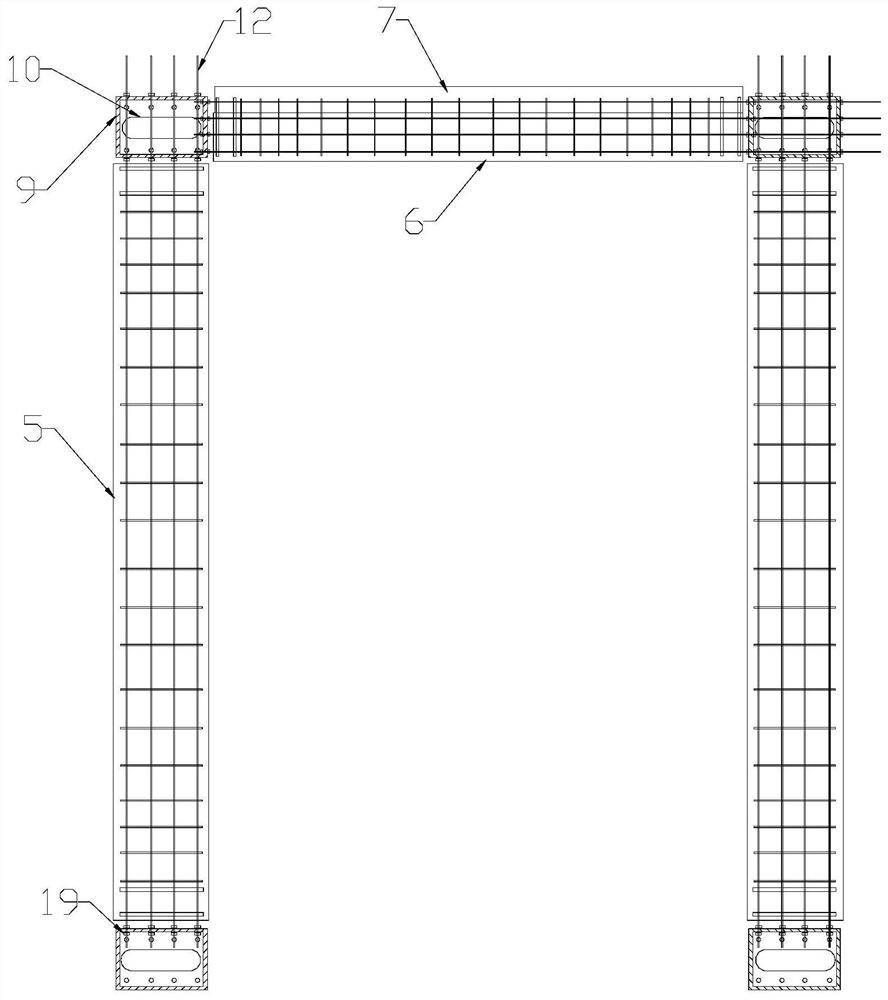

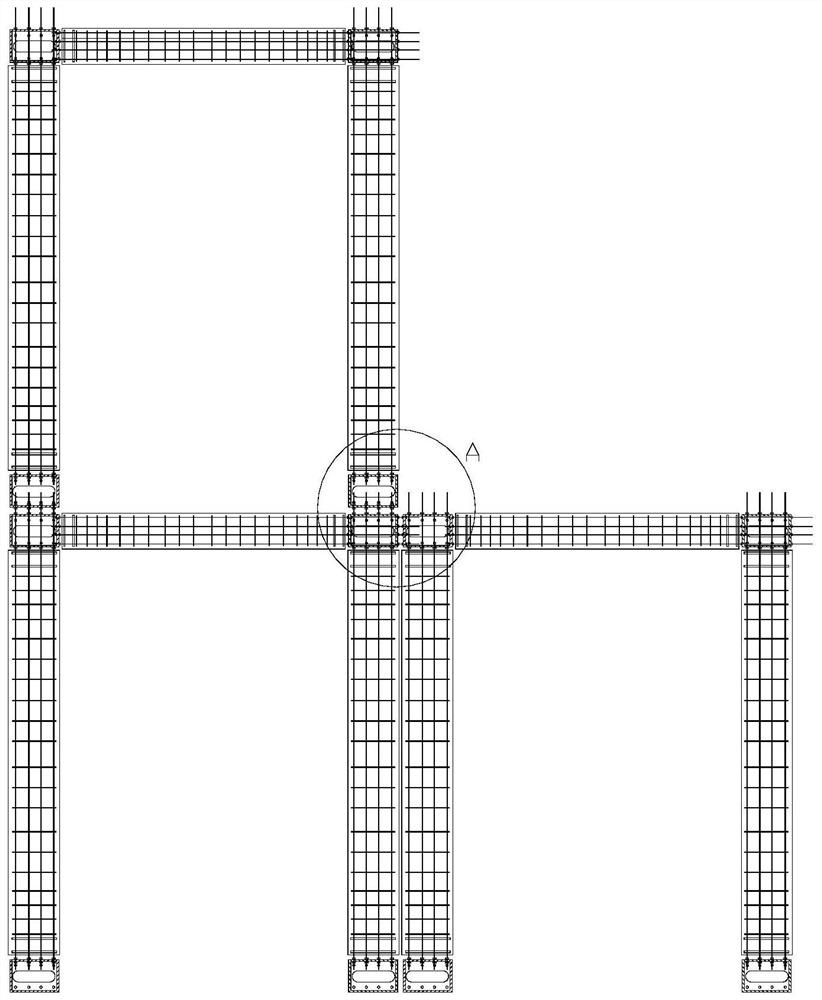

[0047] This embodiment is basically the same as Embodiment 1, the difference is: as Figure 2-4 As shown, the upper and lower ends of the precast concrete column 5 are provided with a hollow square shell 9, each side wall of the square shell 9 is provided with through holes 10 and several connecting holes 11, the precast concrete column 5 and the precast concrete The ends of the beam 6 are provided with reserved exposed steel parts 12 and pre-embedded positioning steel plates 13 for positioning the reserved exposed steel parts 12. The reserved exposed steel parts 12 correspond to the connecting holes 11 of the corresponding side walls one by one. Both the concrete column 5 and the precast concrete beam 6 are pre-embedded with a shaft reinforcement cage 14. The shaft reinforcement cage 14 includes a main reinforcement 15 and a stirrup 16 set outside the main reinforcement 15. The part where the end of the main reinforcement 15 passes through the positioning steel plate 13 is res...

Embodiment 3

[0053] This embodiment is basically the same as Embodiment 2, the difference is: as Figure 5-9 As shown, the precast concrete column 5 is pre-embedded with column steel 20 along the axial direction, and the precast concrete beam 6 is pre-embedded with beam steel 21 along the axial direction. 20 and the side wall ends of the beam profile steel 21 are vertically welded and fixed with a connecting plate 22, the column profile steel 20 and the beam profile steel 21 can also be integrated with the connection plate 22, and the side wall ends of the column profile steel 20 and the beam profile steel 21 are vertically welded and fixed There is a connection plate 22, and the column steel 20 and the beam steel 21 can also be integrated with the connection plate 22. The outer side of the connection plate 22 is welded and fixed with a plurality of steel bar nodes 23, and the outer sides of the column steel 20 and the beam steel 21 are evenly spaced. A stirrup 16, the stirrup 16 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com