Gas proportional valve

A gas proportional valve and valve body technology, which can be applied to lift valves, sliding valves, valve details, etc., can solve problems such as leakage, low practicability, and complicated valve switching, and achieve the effect of reducing the difficulty of use and being convenient to use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

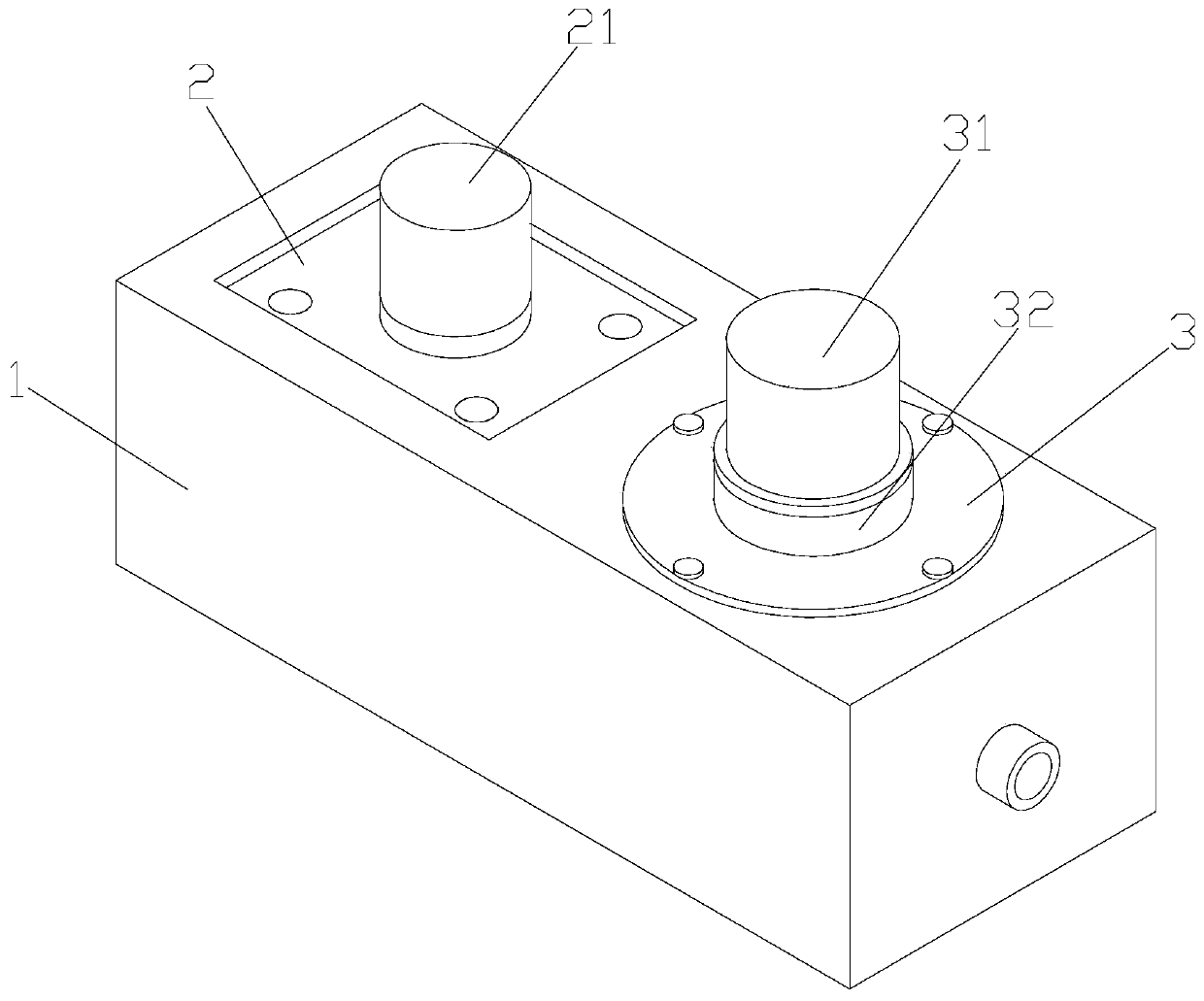

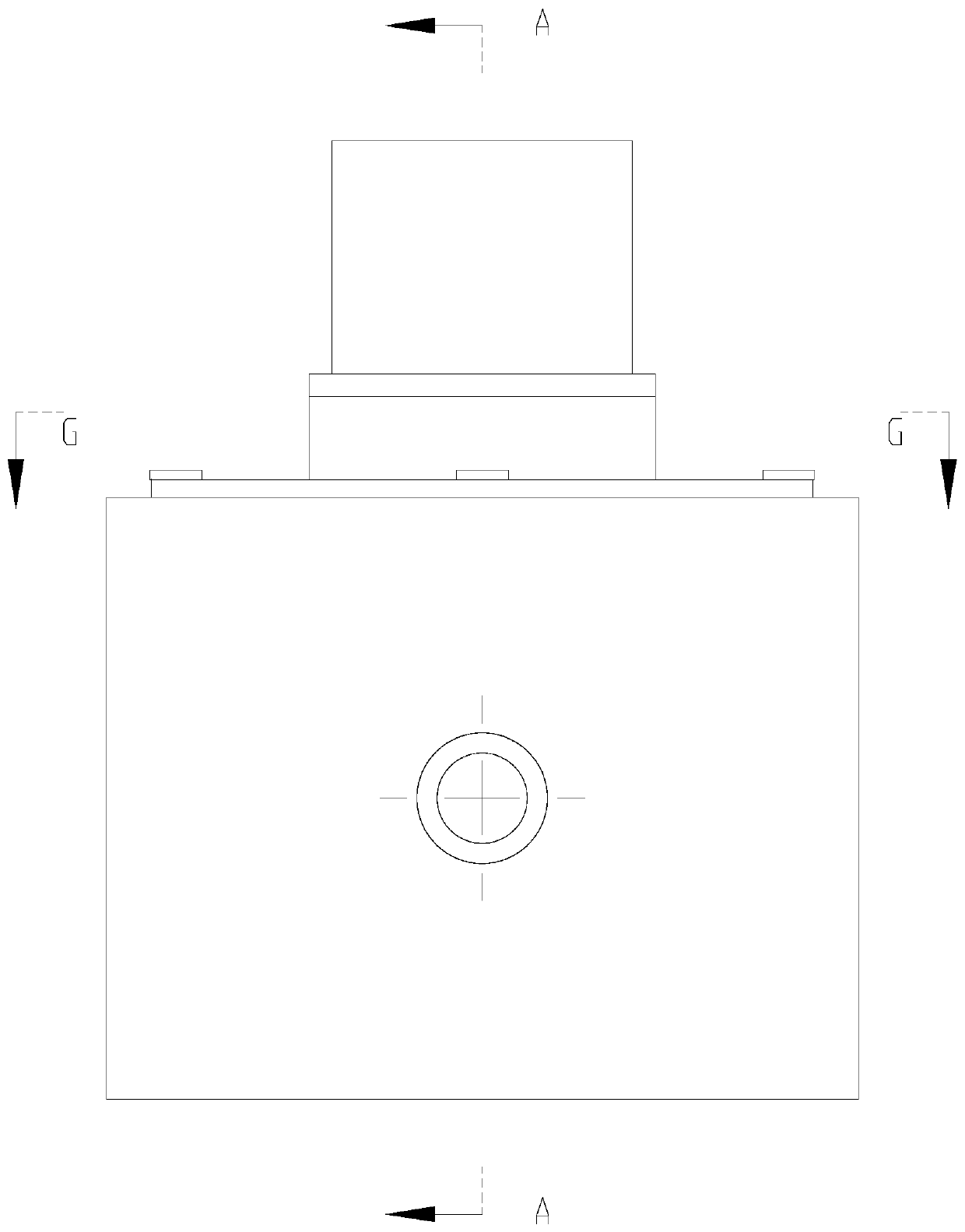

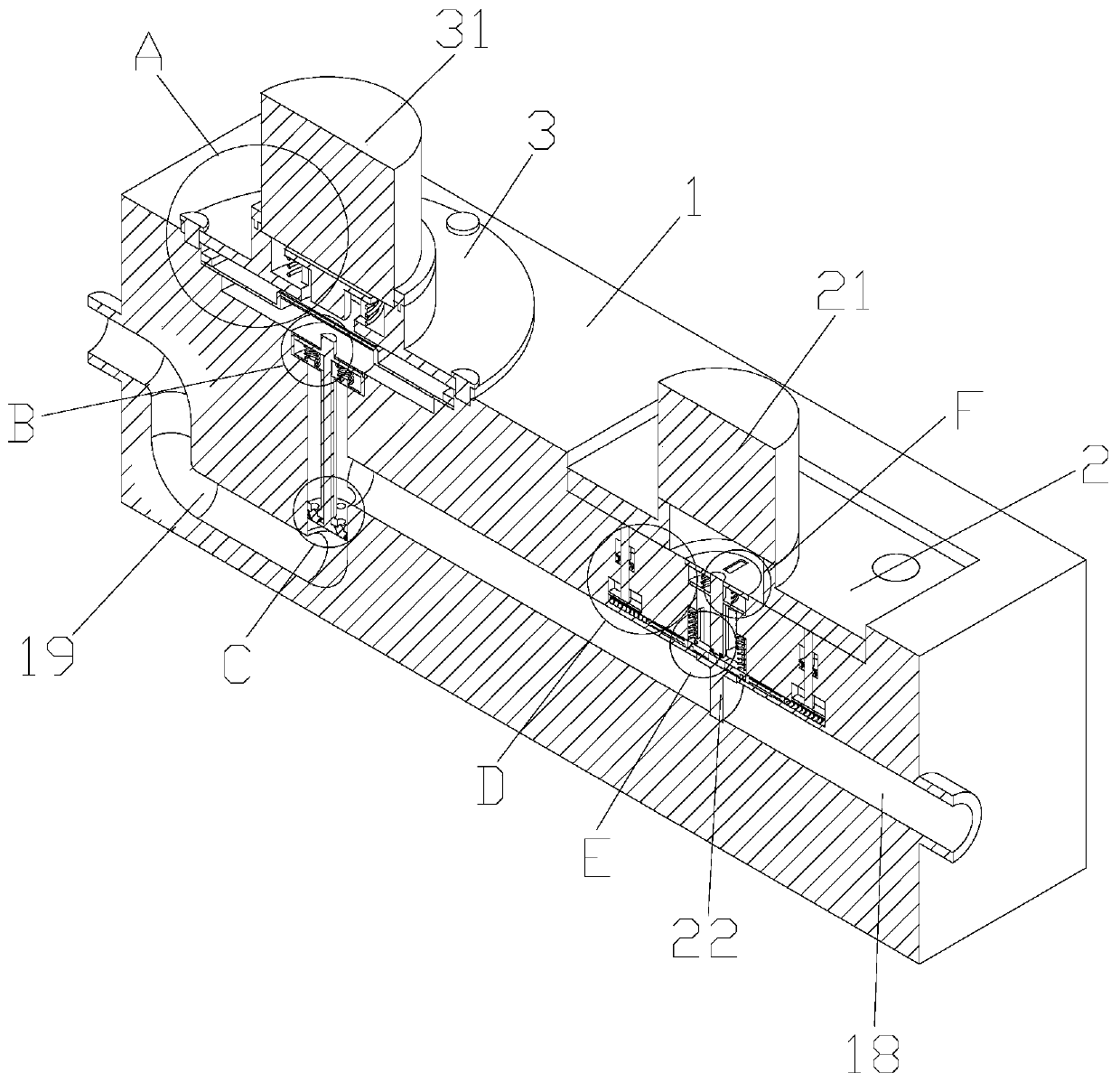

[0030] Such as Figure 1-14 As shown, a gas proportional valve includes a valve body 1, a cut-off device and an adjustment device arranged on the valve body 1, the valve body 1 is provided with an air inlet chamber 18 and an air outlet chamber 19, and the inlet chamber 1 The air chamber 18 communicates with the air outlet chamber 19, and the top of the valve body 1 is provided with a first installation groove, and the cut-off device includes a first installation plate 2 arranged in the first installation groove, and a first installation plate 2 arranged in the first installation groove. The first electromagnet 21 on the first mounting plate 2 and the first push rod 11 located below the first electromagnet 21, the first mounting plate is fixedly connected in the first mounting groove by screws, and the air intake cavity The top of 18 is provided with a first through cavity, the air inlet cavity 18 is provided with a first baffle 22, and the top of the first baffle 22 is provide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com