Micron-scale concentricity detector and detection method thereof

A concentricity and detector technology, applied in the direction of instruments, measuring devices, mechanical measuring devices, etc., can solve problems such as low transmission performance, inability to guarantee the concentricity requirements of the ceramic ferrule and the front cover, and inability to find reference point positioning and calibration, etc. Achieve high measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

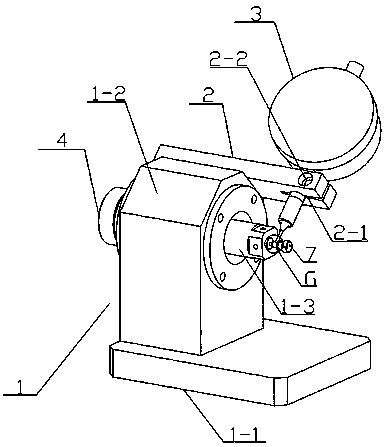

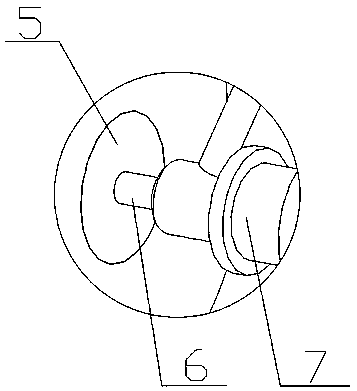

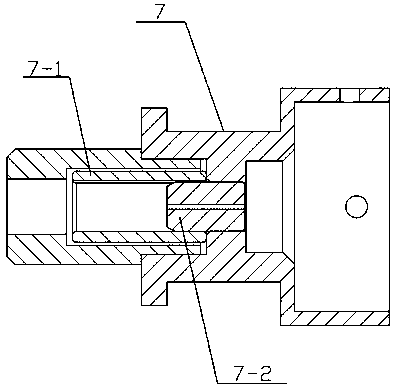

[0020] Such as Figure 1~4 As shown, the present invention provides a micron-level concentricity detector, including a horizontal rotation mechanism 1, a watch holder 2 and a dial indicator 3, and the horizontal rotation mechanism 1 includes a base plate 1-1, a bearing seat 1-2 and a rotating shaft 1-3, the rotating shaft 1-3 is connected to the bearing seat 1-2 through bearing rotation, and the bearing seat 1-2 is connected to the bottom plate 1-1, and both ends of the rotating shaft 1-3 extend out of the bearing seat 1-2, and one end of the rotating shaft 1-3 is connected with a rotary handle 4, and the other end is coaxially inserted with a connecting sleeve 5, and the first ceramic ferrule 6 is coaxially inserted in the connecting sleeve 5, so The end of the first ceramic ferrule 6 away from the connecting sleeve 5 is connected to the optical fiber adapter 7, the watch clip 2 is connected to the bearing seat 1-2 by bolts, and the watch clip 2 is provided with a clip watch ...

Embodiment 2

[0024] refer to Figure 1~4 , the present invention also provides a detection method based on the micron level concentricity detector of embodiment 1, comprising the steps of:

[0025] 1) Externally connect the first ceramic ferrule 6 from the front cover end of the fiber optic adapter 7, insert the first ceramic ferrule 6 into the ceramic sleeve 7-1 of the fiber optic adapter 7, and make the first ceramic ferrule 6 and the inside of the fiber optic adapter 7 The second ceramic ferrule is concentric;

[0026] 2) Insert the end of the first ceramic ferrule 6 away from the fiber optic adapter 7 into the connecting sleeve 5 on the rotating shaft 1-3 of the horizontal rotation mechanism 1, and pass the gauge head of the dial indicator 3 to the outer periphery of the front cover of the fiber optic adapter 7 make contact measurements;

[0027] 3) By turning the rotating handle 4, the fiber optic adapter 7 is rotated once, and the concentricity between the front cover of the fiber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com