Electromechanical separation water meter

A technology of electromechanical separation and water meter, which is applied in the direction of measuring devices, instruments, liquid/fluid solid measurement, etc., can solve the problems of difficult to guarantee the sampling distance, shortened battery life, insufficient trigger distance, etc. Maintenance cost and the effect of shortening the sensing distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

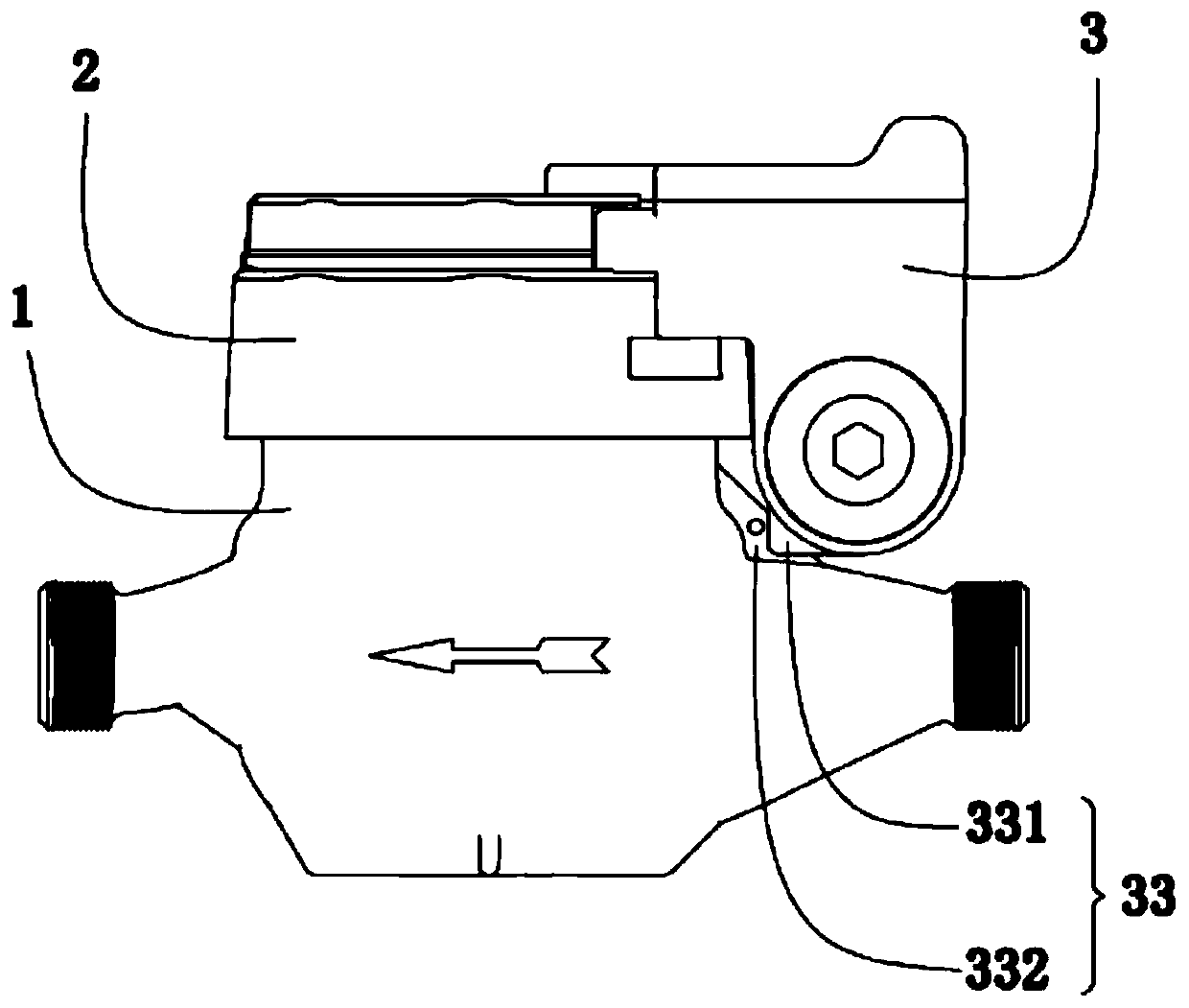

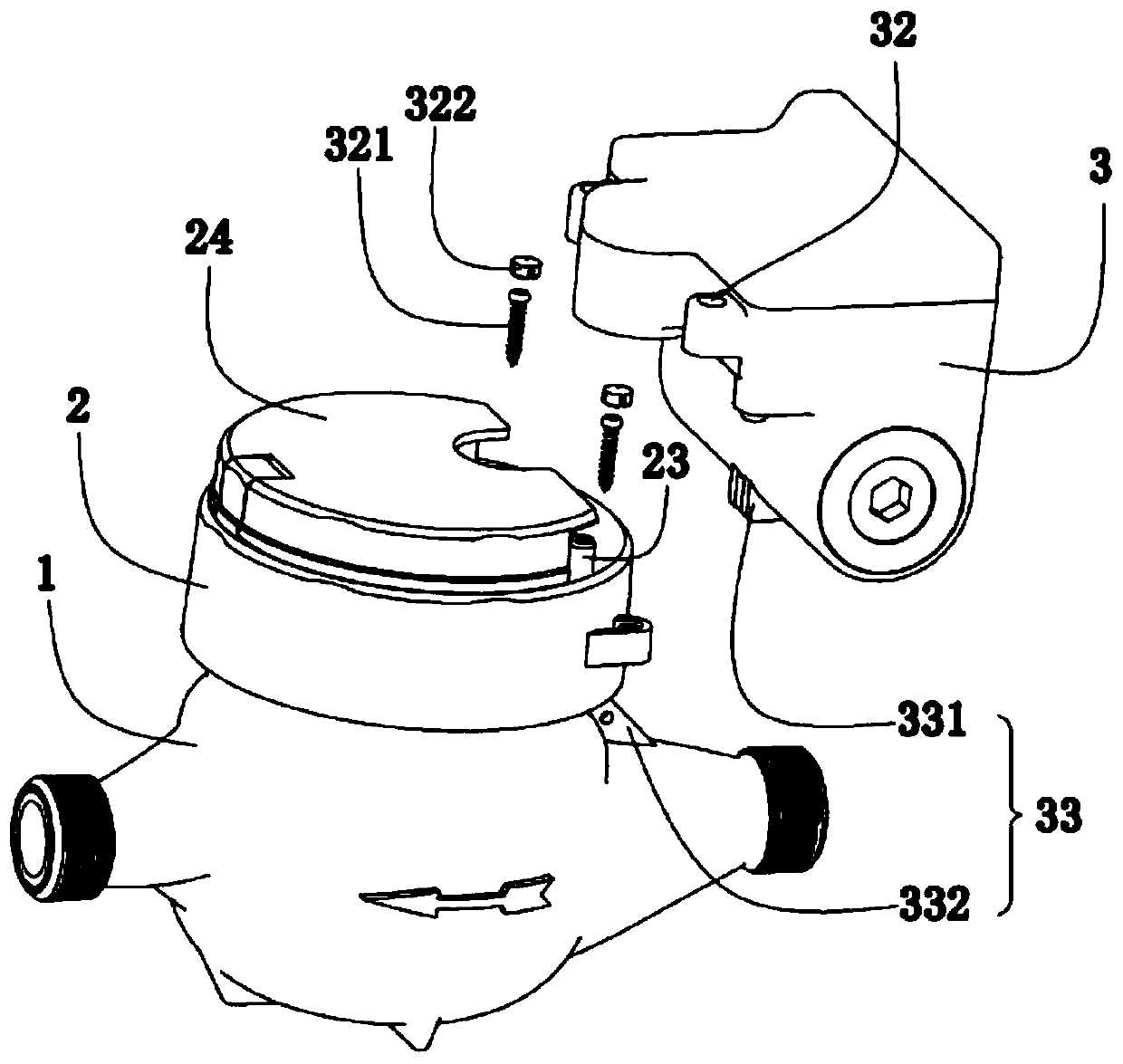

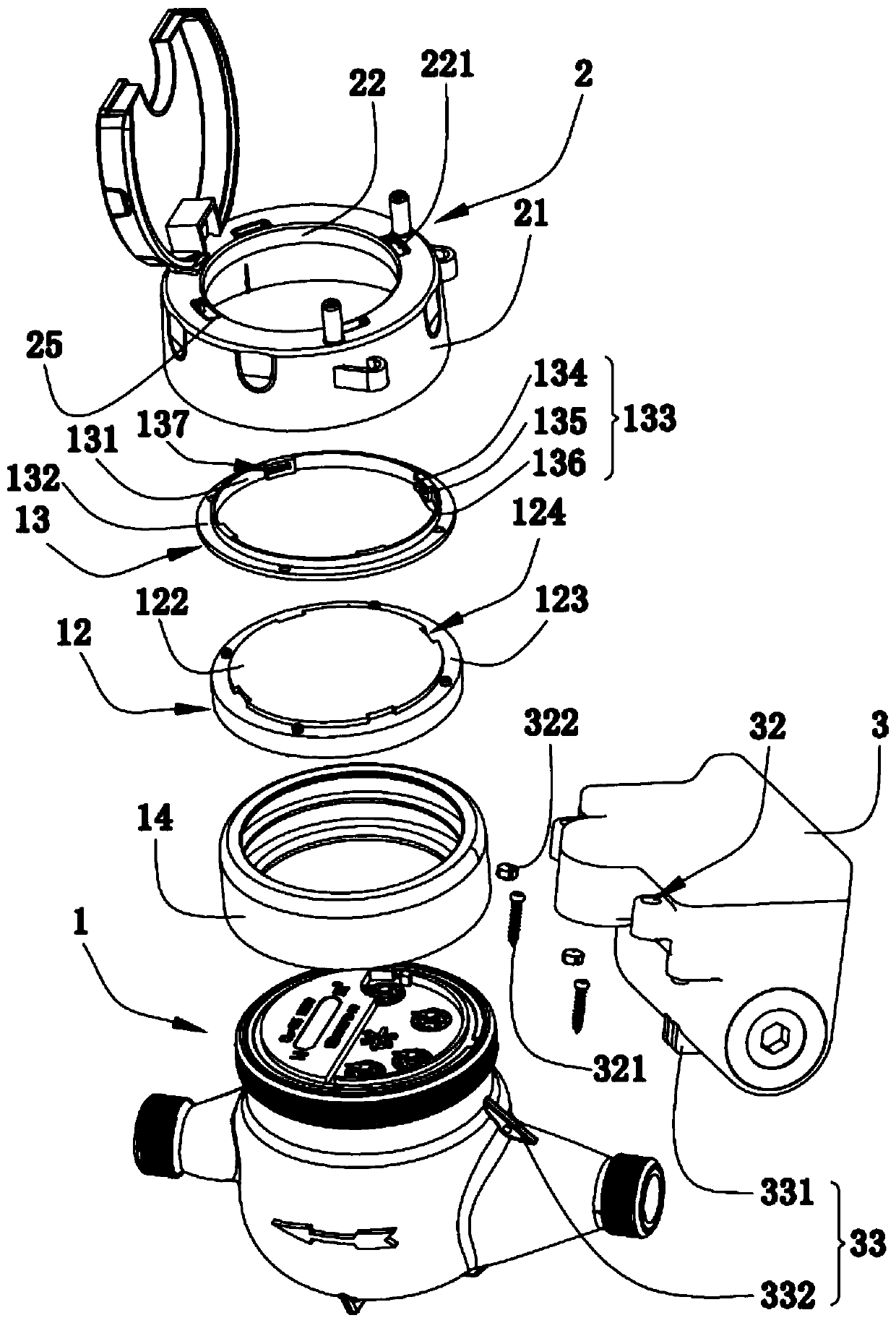

[0036] This embodiment provides a water meter with electromechanical separation and easy disassembly. Figure 1 to Figure 3 , in this embodiment, the water meter includes a metering base meter composed of a base meter body 1 and a base meter upper cover 2 and an electric control body 3, and the base meter body 1 includes a dial 11, a dial glass 12, and a dial glass 12. The clamping locking cover and the base meter casing 15 threadedly connected with the clamping locking cover, the clamping locking cover includes a clamping part 133, and the base meter upper cover 2 is detachably connected to the base meter main body 1 through the clamping part 133 , the electronic control main body 3 is fixedly connected with the base meter upper cover 2, and the electronic control main body 3 cooperates with the base meter main body 1 to form a locking structure 33 for limiting the clockwise or counterclockwise rotation of the base meter upper cover 2, and the base meter upper cover 2 Through...

Embodiment 2

[0045] This embodiment provides an electromechanical separation water meter, combined with reference Figure 4 to Figure 6 , in this embodiment, the electromechanical separation water meter includes a metering base meter composed of a base meter body 1 and a base meter upper cover 2 and an electric control body 3, the base meter body 1 includes a dial 11 and a dial glass 12, and the dial 11 is provided with a In the communication pointer 111 of non-magnetic sampling, the upper surface of the dial glass 12 is partially sunken to form an assembly groove 121. The electronic control body 3 includes a sensing end 31, and the sensing end 31 abuts in the assembly groove 121 of the dial glass 12 and is connected to the communication pointer 111. relatively.

[0046] In this embodiment, the non-magnetic induction principle of the electromechanical separation water meter is based on the LC oscillating circuit, and the induction terminal 31 of the electronic control body 3 is provided wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com