State monitoring method and system based on multivariable state estimation

A state estimation, multi-variable technology, applied in the testing, calculation, and measurement devices of machines/structural components, etc., can solve the problems of inability to comprehensively evaluate the state of equipment, no fusion of multi-variable feature parameters, and no feature parameters for equipment selection, etc. Achieve the effect of retaining long-term development trends, avoiding interference, and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

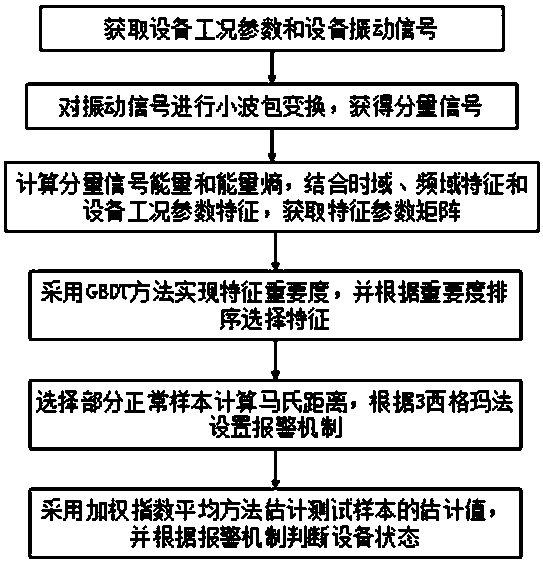

[0051] Embodiment one, such as figure 1 As shown, a state monitoring method based on multivariate state estimation, taking a certain type of motor as an example, the rotation speed of the motor is 2500rpm, including steps:

[0052] A) Collect equipment operating condition parameter signals and vibration signals, the sampling frequency is 25600Hz, a total of m groups of vibration signal samples, m=400,

[0053] Perform feature extraction on each group of equipment signal samples, obtain n1 features of each group of equipment vibration signal samples and n2 features of the working condition parameter signal, and obtain an m×n-dimensional feature parameter matrix, n=n1+n2, including the steps :

[0054] A1) Extract 15 time-domain features of the vibration signal samples of each group of equipment. The 15 time-domain features include mean value, absolute mean value, variance, standard deviation, maximum value, minimum value, peak-to-peak value, effective value, skewness, peak ind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com