Circulator and implementation method thereof

A circulator, circular technology, applied in the direction of waveguide type devices, electrical components, circuits, etc., can solve the problems of high cost, difficult shell thread processing, high assembly cost, meet the requirements of high concentricity and save production time , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

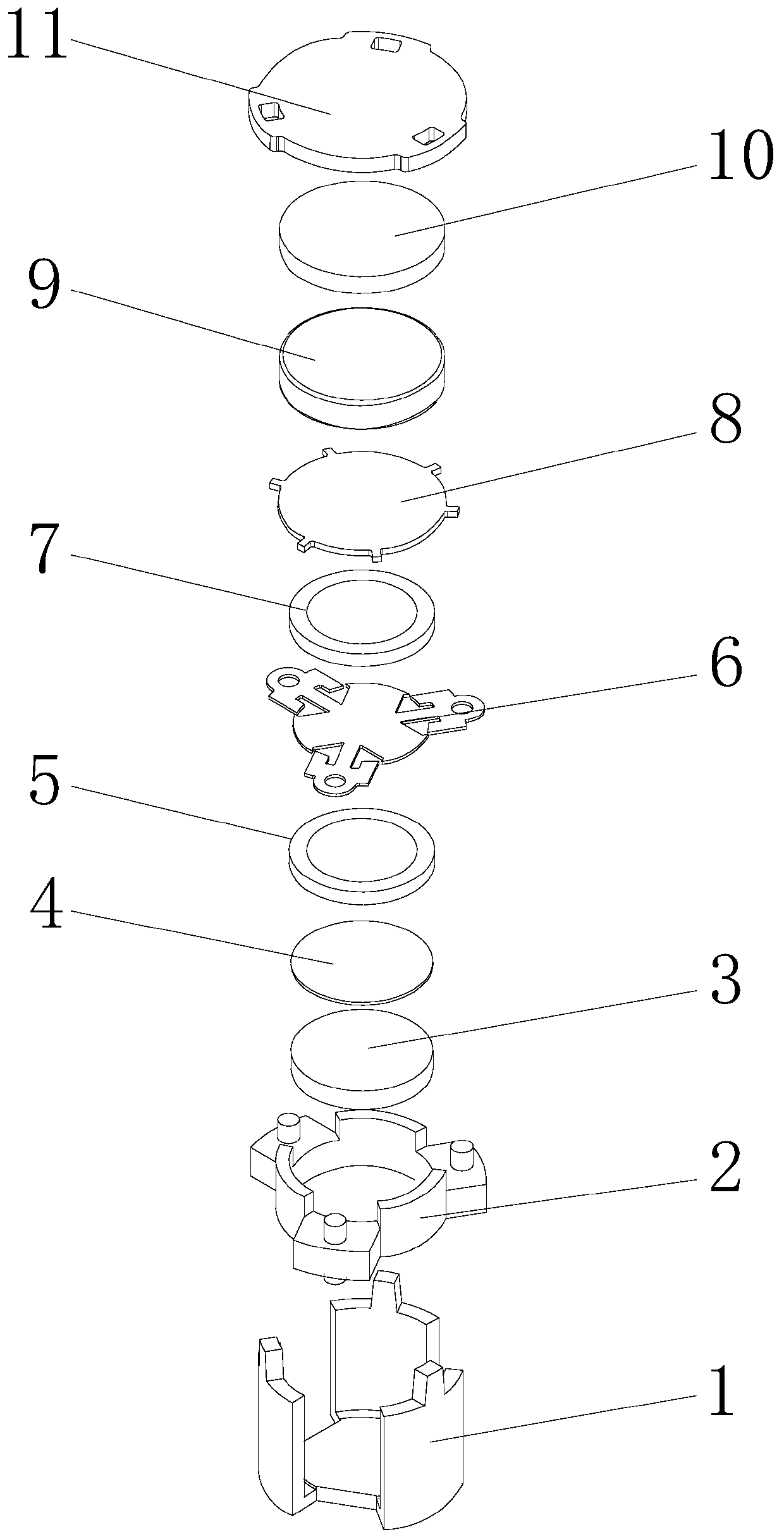

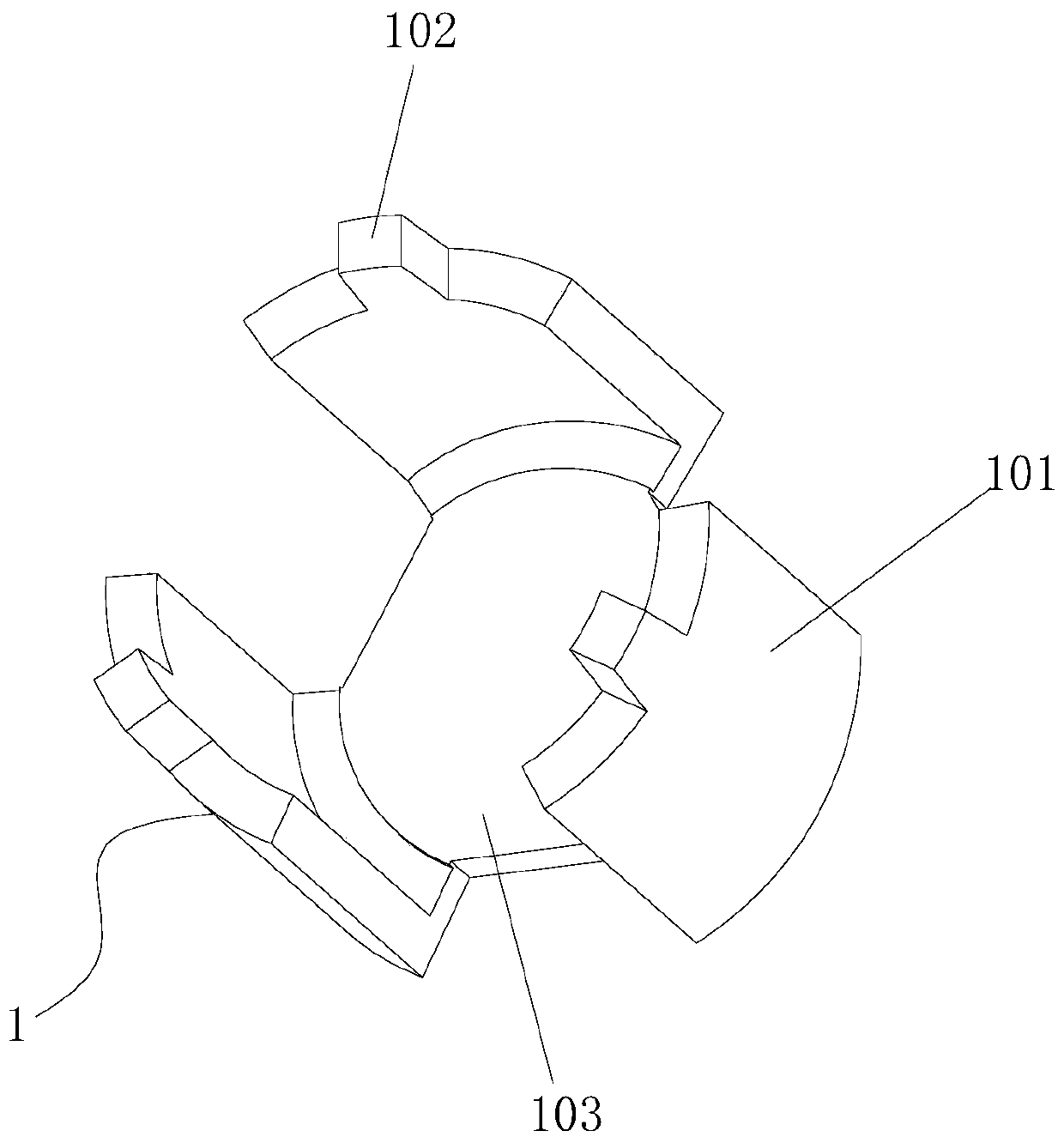

[0037] see Figure 1-8 , the present invention provides the following technical solutions: a circulator, including a housing 1, the interior of the housing 1 is sequentially provided with a terminal assembly 2, a lower magnet 3, a lower shim 4, a lower ferrite 5, a center Conductor 6, upper ferrite 7, upper shim plate 8, upper magnet 9 and temperature compensation plate 10, cover plate 11 is connected to the top of housing 1, housing 1 includes circular bottom plate 103, the circumference of circular bottom plate 103 There are several arc-shaped limiting plates 101 arranged vertically with the circular bottom plate 103 evenly on the top, and a top cylinder 102 is connected above the arc-shaped limiting plate 101. The end hole 111 of the casing 1 and the cover plate 11 are bent and fixed after the top cylinder 102 passes through the end hole 111 .

[0038] Specifically, there are three arc-shaped limiting plates 101 in total, and the three arc-shaped limiting plates 101 are di...

Embodiment 2

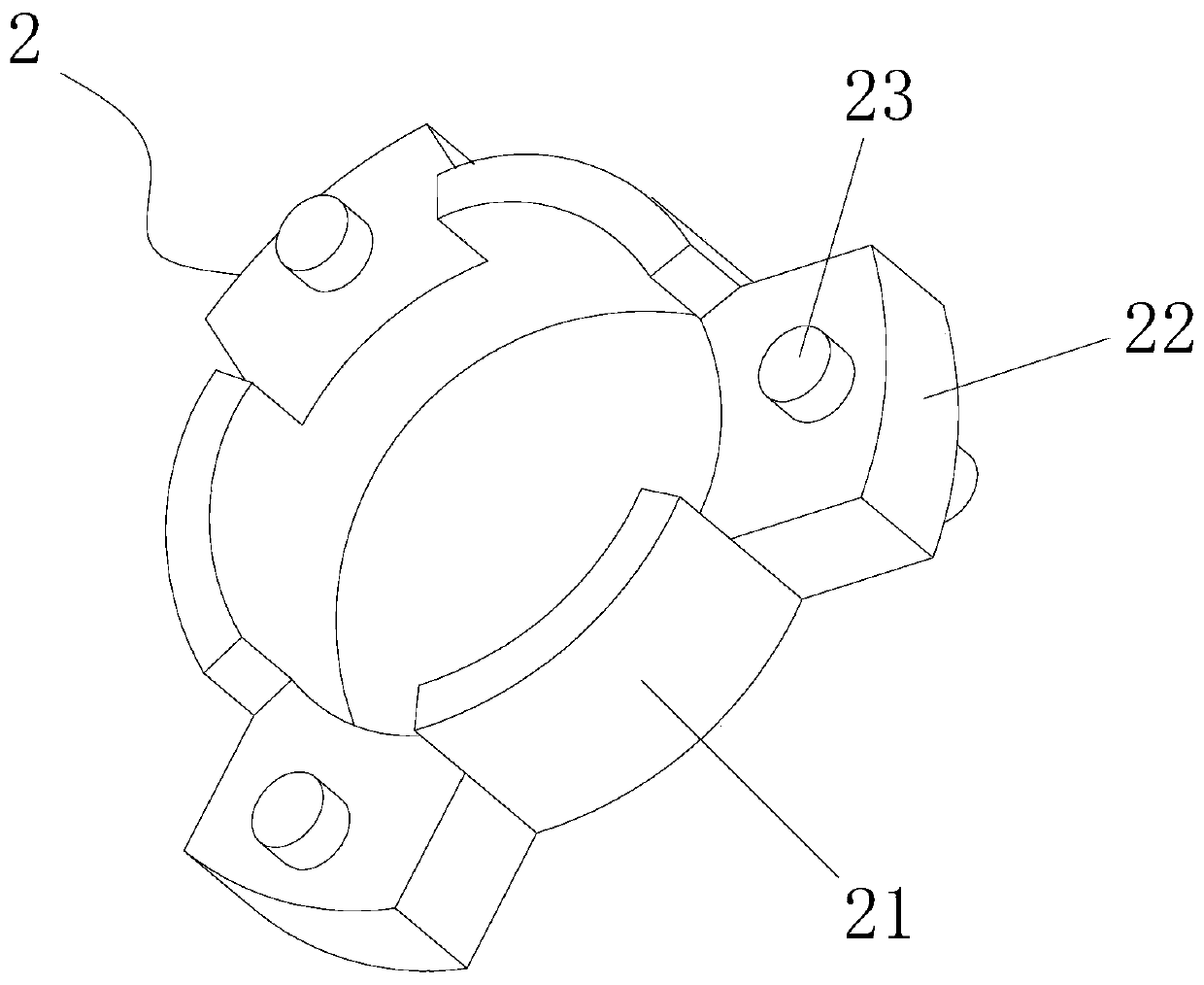

[0042] This embodiment differs from Embodiment 1 in that: specifically, the terminal assembly 2 includes three arc-shaped positioning plates 21 corresponding to the arc-shaped limiting plates 101, and the three arc-shaped positioning plates 21 form a closed-loop hollow column Body space, the center of circle of three arc-shaped positioning plates 21 is concentric with the circular center formed by three PIN needles 23, the lower magnet 3, the lower shim plate 4, the lower ferrite 5, the central conductor 6 and the upper ferrite 7 Located inside the three arc-shaped positioning plates 21.

[0043] By adopting the above technical scheme, the lower magnet 3, the lower shim plate 4, the lower ferrite 5, the central conductor 6 and the upper ferrite 7 placed inside the arc positioning plate 21 are limited and fixed, which can satisfy High concentricity requirement between ferrite and center conductor.

[0044] Specifically, a horizontal extension block 22 is connected at the inter...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap