Method for operating a battery sensor, and battery sensor

一种电池传感器、电池电压的技术,应用在电气测量仪器的零部件、测量电流/电压、基本电气元件的改进等方向,能够解决很难重复校准、短时间内施加、参考电流小等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064]A further explanation of the present invention is given below, on the one hand to explain the function, on the other hand, the features described herein can also be combined with other features described as required. These features can also be combined with one another and can represent important aspects for the invention individually or in combination.

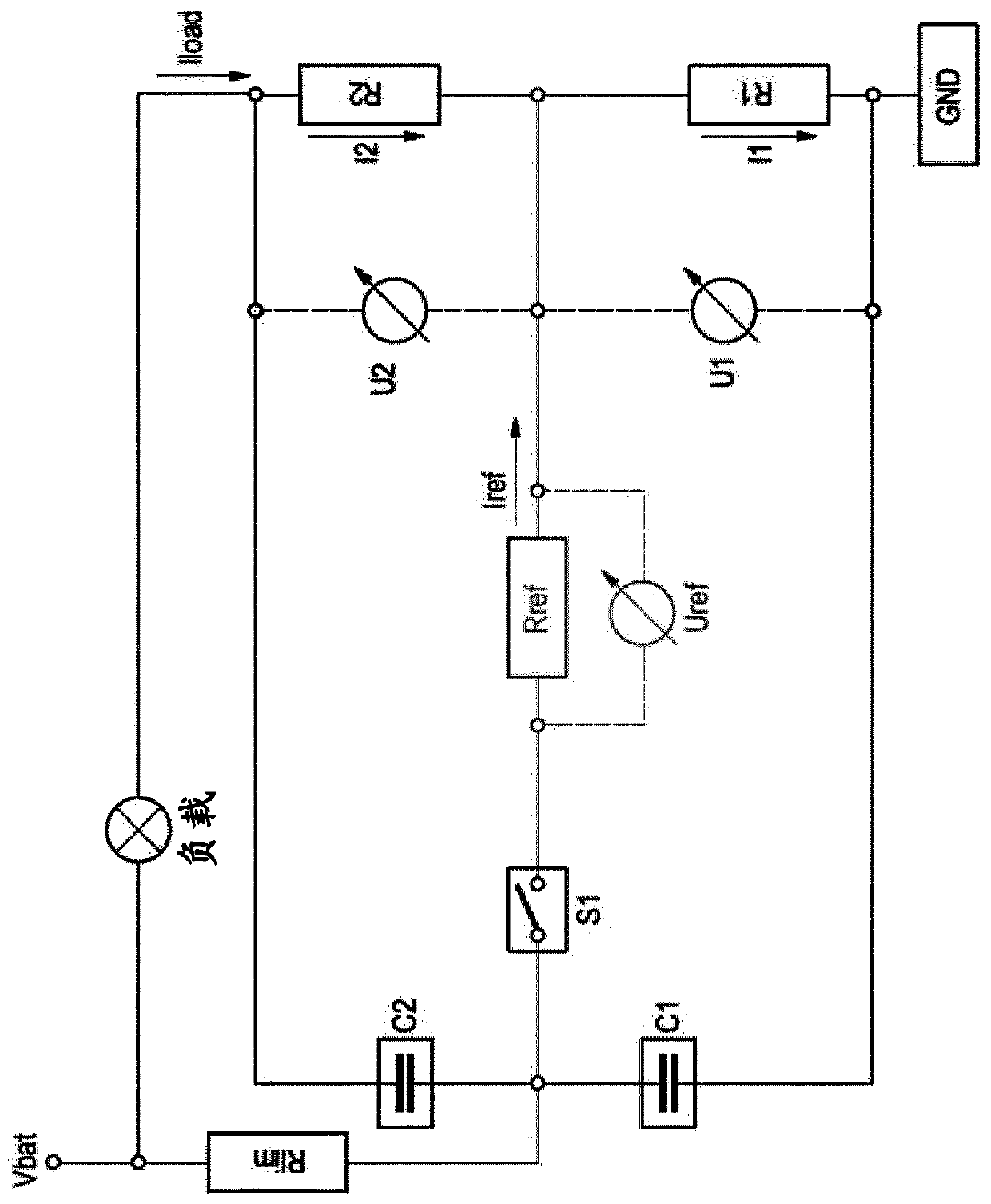

[0065] For this, first refer to figure 1 .

[0066] figure 1 A prior art battery sensor is shown with which a calibration method can be carried out. However, three A / D converters U1, U2 and Uref are required, and none of these A / D converters can realize uninterrupted measurement of Vbat.

[0067] The measuring resistor set has a first measuring resistance element R1 and a second measuring resistance element R2 via which a time-varying load current Iload is conducted. This load current Iload initially comes from the battery, which in terms of voltage is shown at figure 1 Expressed in Vbat. The load current Iload al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com