Panel cutting equipment carrying table replacement device and panel cutting equipment

A technology of cutting equipment and carrier, applied in welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problem of inconvenient replacement of carrier, and achieve the effect of convenient replacement of carrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

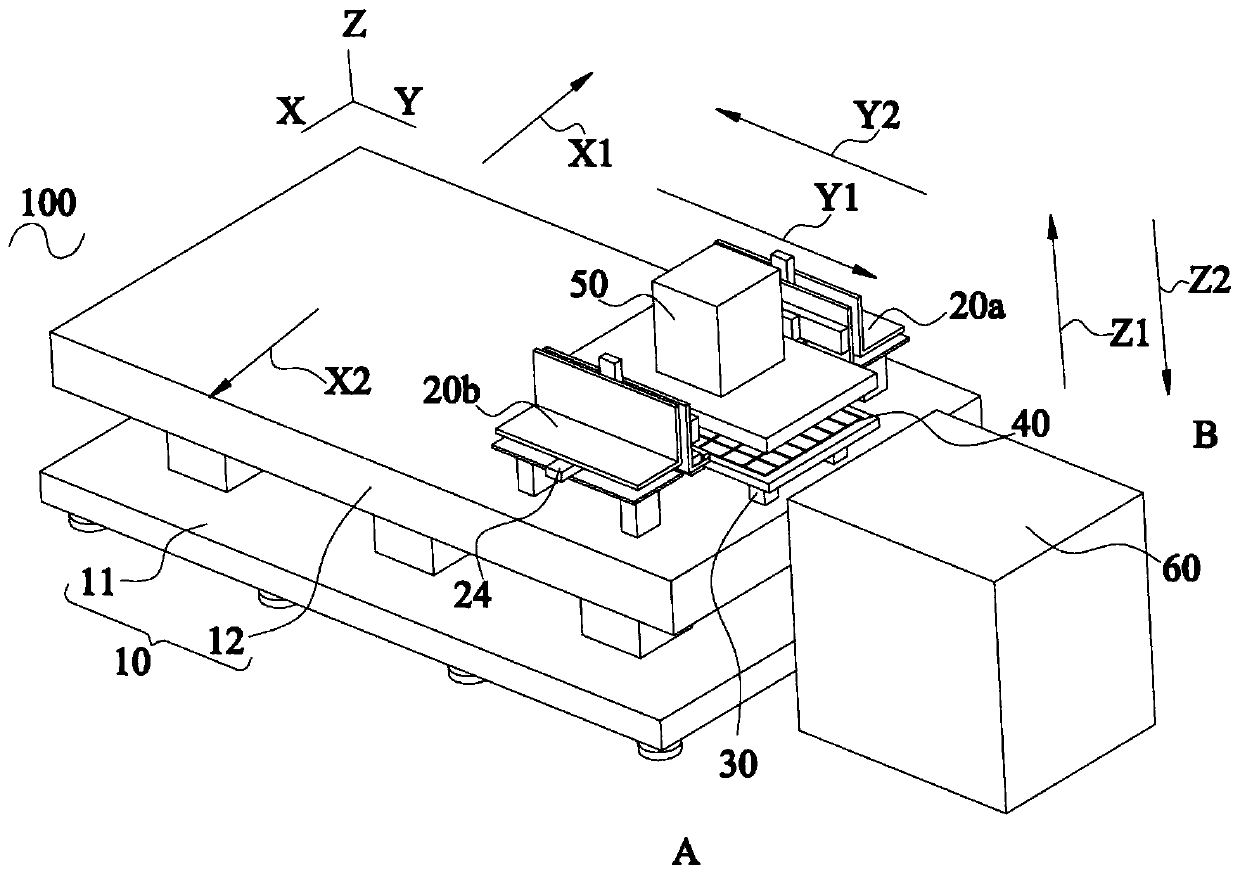

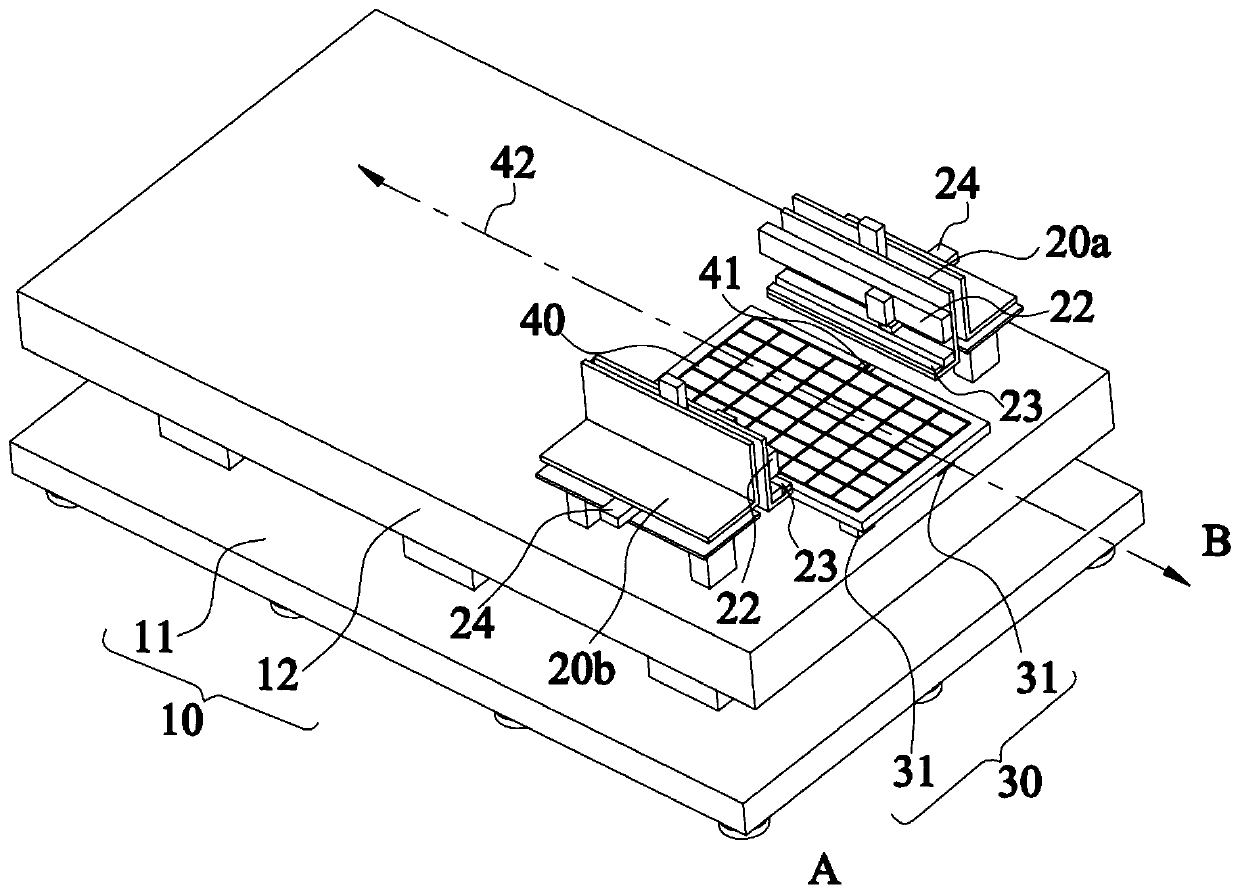

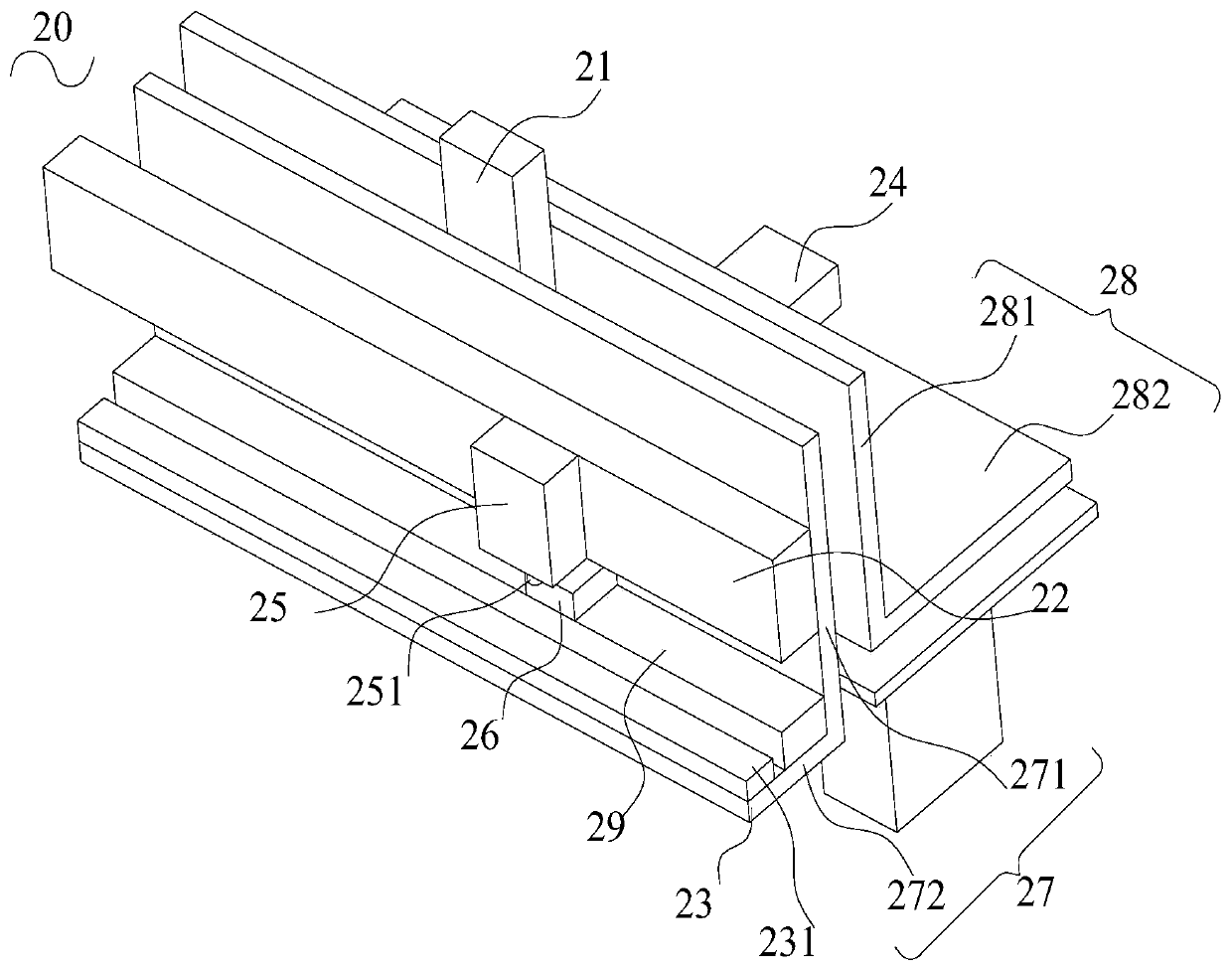

[0029] The present invention will be described in detail below with reference to the embodiments shown in the drawings. However, it should be noted that these embodiments do not limit the present invention, and those of ordinary skill in the art make functional, method, or structural improvements based on these embodiments. Equivalent changes or substitutions fall within the protection scope of the present invention.

[0030] Horizontal correspondence of this application figure 1 The X direction in the vertical corresponds to figure 1 The Y direction in the vertical direction corresponds to figure 1 In the Z direction.

[0031] This application uses the longitudinal symmetrical centerline 42 of the carrier 40 (see figure 2 ) Is the reference line, toward the symmetric center line 42 is inward, and away from the symmetric center 42 is outward.

[0032] In this application, the left side is the side with label A, and the right side is the side with label B.

[0033] Such as figure 1 As...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap