Torsion beam limiting block structure and limiting system

A technology of limit block and torsion beam, which is applied in the interconnection system, the cantilever mounted on the pivot, the suspension, etc., can solve the problem of looseness of the limit block, abnormal noise of extrusion, and buckle of the limit block Easy to break and other problems, to achieve the effect of lightening the overall structure, meeting the limit demand, and improving the driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

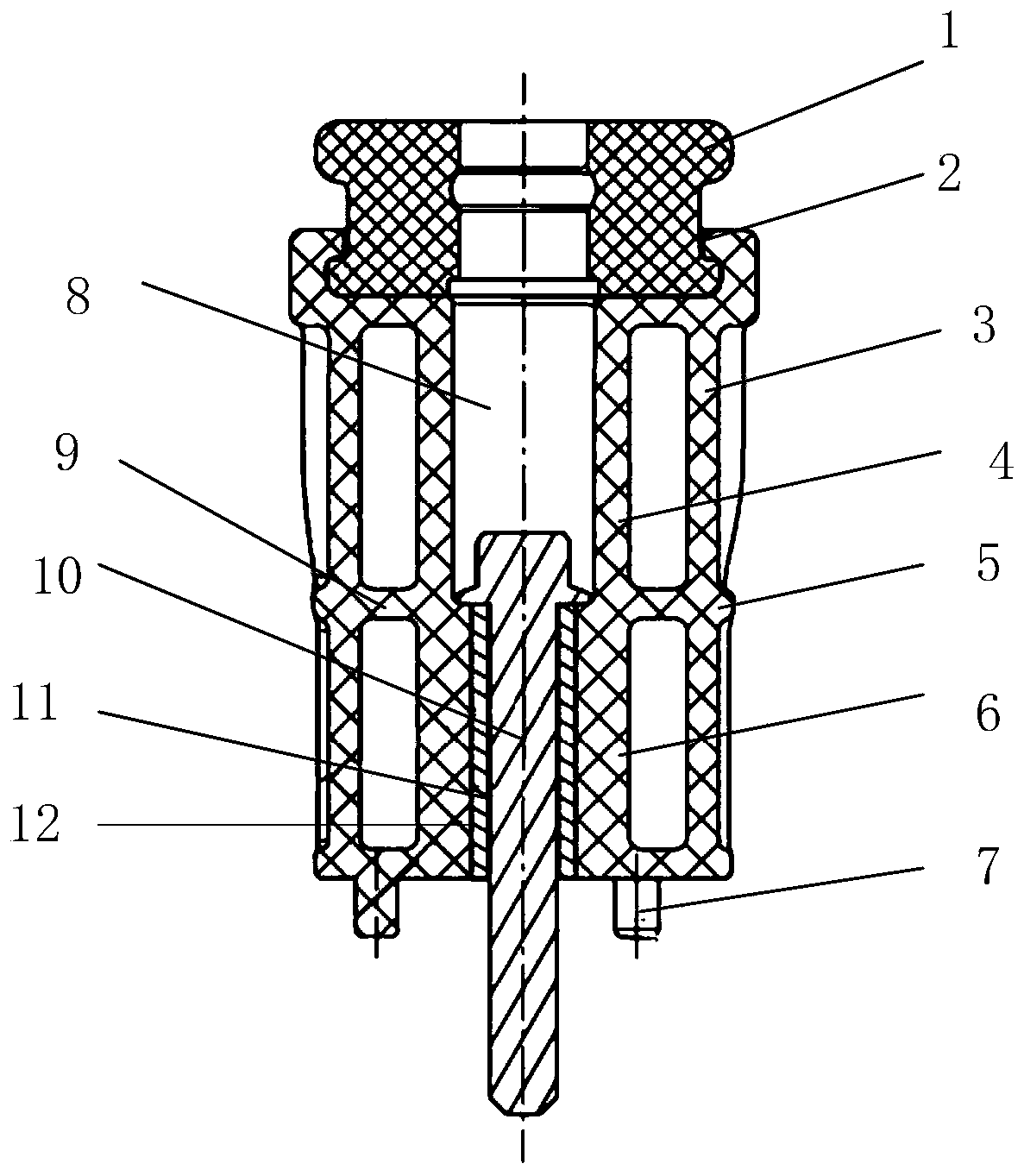

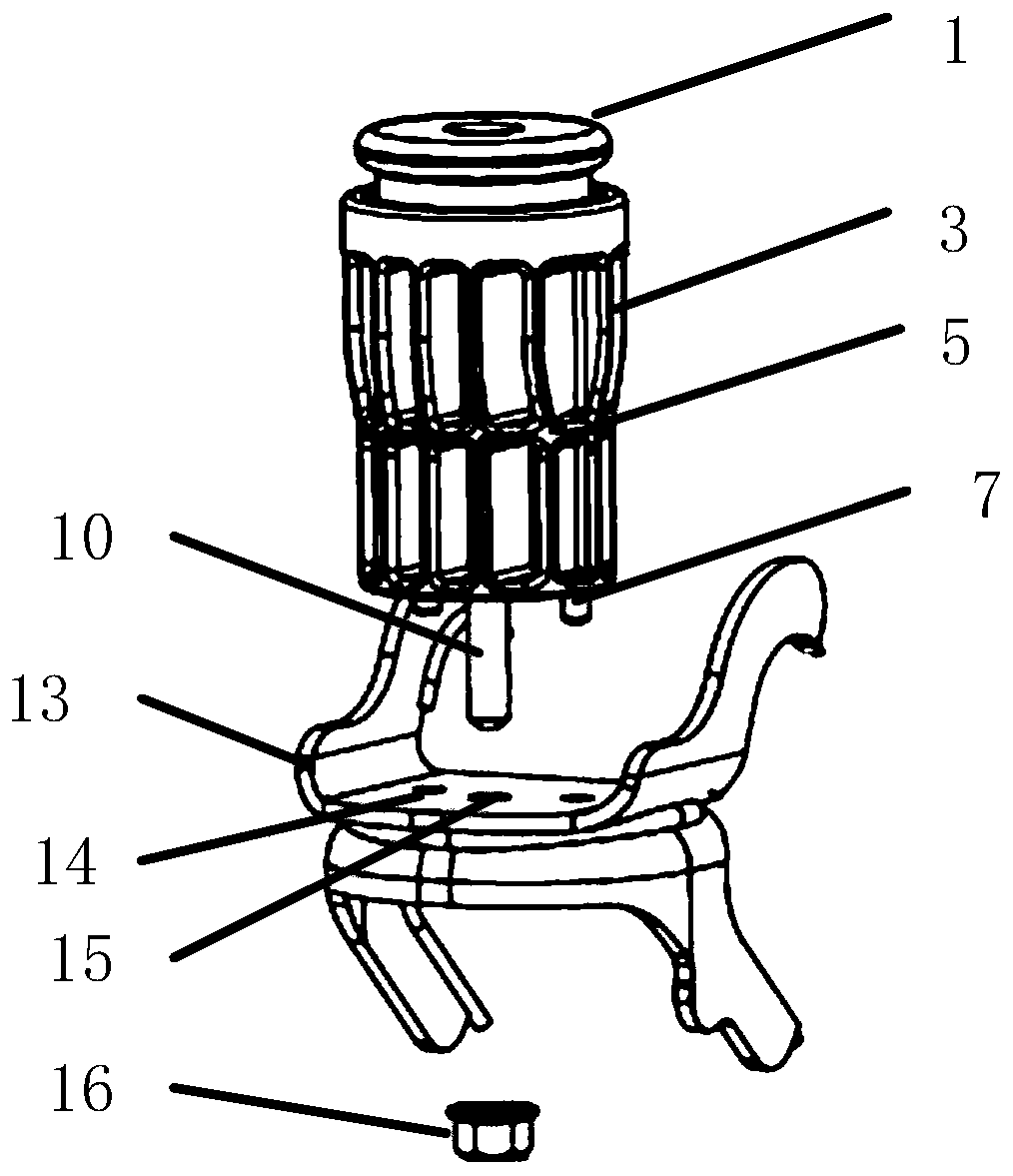

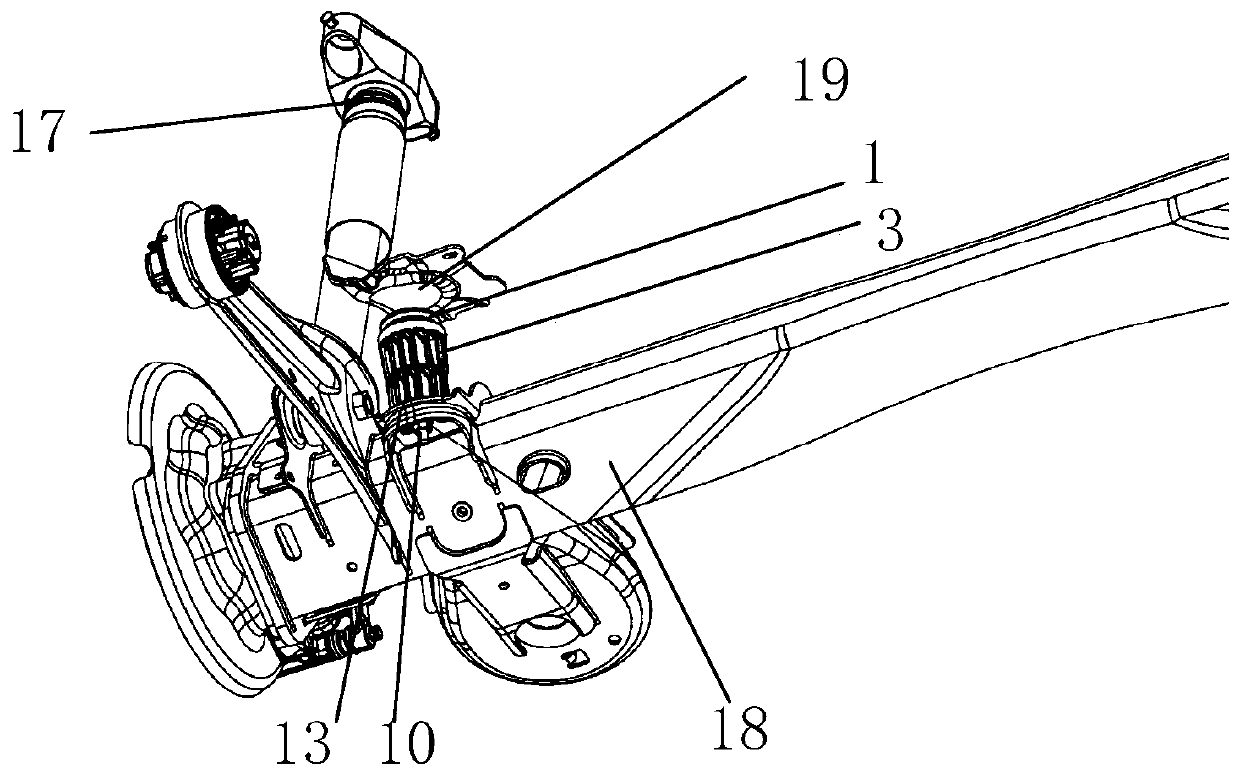

[0042] Example 1, see figure 1 , image 3 As shown, the embodiment of the present invention discloses a torsion beam limiting block structure, which includes:

[0043] Plastic base, the upper end is provided with a ring-shaped mounting part, the inner peripheral side wall of the mounting part is provided with a mounting groove, and the outer peripheral edge of the lower end of the mounting part is provided with twelve outer vertical bars 3 distributed along the circumferential direction, understandably Yes, the number of outer vertical bars 3 can be set according to the required strength and space of the outer vertical bars 3, subject to actual needs. In this embodiment, the front of the plastic base, that is, the direction facing the front of the vehicle, and the rear, That is, the direction facing the rear of the vehicle has five outer vertical bars 3 respectively, while the left side, that is, the direction facing the left side of the vehicle, and the right side, that is, th...

Embodiment 2

[0046] Embodiment 2, continue to refer to figure 1 , on the basis of Embodiment 1, the inner peripheral edge of the lower end of the installation part is also provided with twelve inner vertical bars distributed along the circumferential direction, and the connection line between each inner vertical bar and the outer vertical bar 3 at the corresponding position falls In the radial direction of the plastic base, the inner vertical bars extend downward along the axial direction of the plastic base to the inner peripheral edge of the bottom, and the middle parts of two adjacent inner vertical bars pass through inner Circumferential stiffener connection.

[0047] Moreover, the connecting point between the outer vertical bar 3 and the outer circumferential reinforcing rib 5 and the connecting point between the inner vertical bar and the inner circumferential reinforcing rib at the corresponding position pass through a radial direction extending radially along the plastic base. Rib...

Embodiment 3

[0048] Embodiment 3, refer to figure 1 , figure 2 , on the basis of Example 2, the inner periphery of the lower end of the mounting part is provided with a cylinder extending downward, and the radial reinforcing rib 9 is a cuboid, and its length along the axial direction of the plastic base is the same as that of the outer The vertical bars 3 have the same length, and the radial ribs 9 connect the outer vertical bars 3 and the upper end to the lower end of the cylinder.

[0049] In this embodiment of the above-mentioned structure, the inner vertical bar is directly poured into a cylindrical shape, without the need for inner circumferential reinforcing ribs, and the structural strength is further strengthened, and the reinforcing rib 9 connects the outer vertical bar 3 and the upper end to the lower end of the cylinder, so that The structural strength of the plastic base is further enhanced.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com