Iron chipping storage box in factory

A technology for storage boxes and iron filings, applied in the direction of internal accessories, loading/unloading, unloading devices, etc., can solve the problem that the iron filings box is not easy to dump, and achieve the effect of easy movement and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

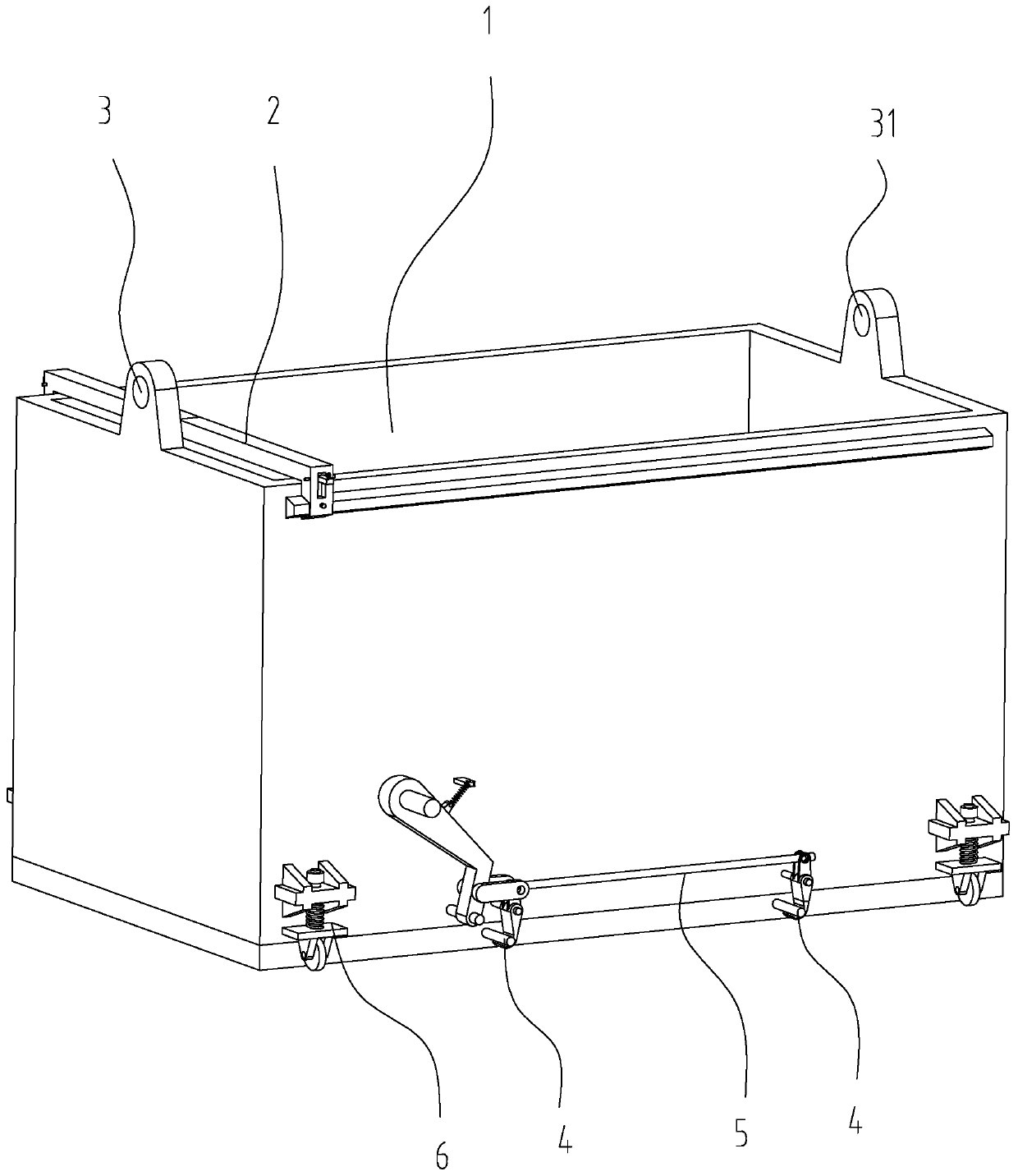

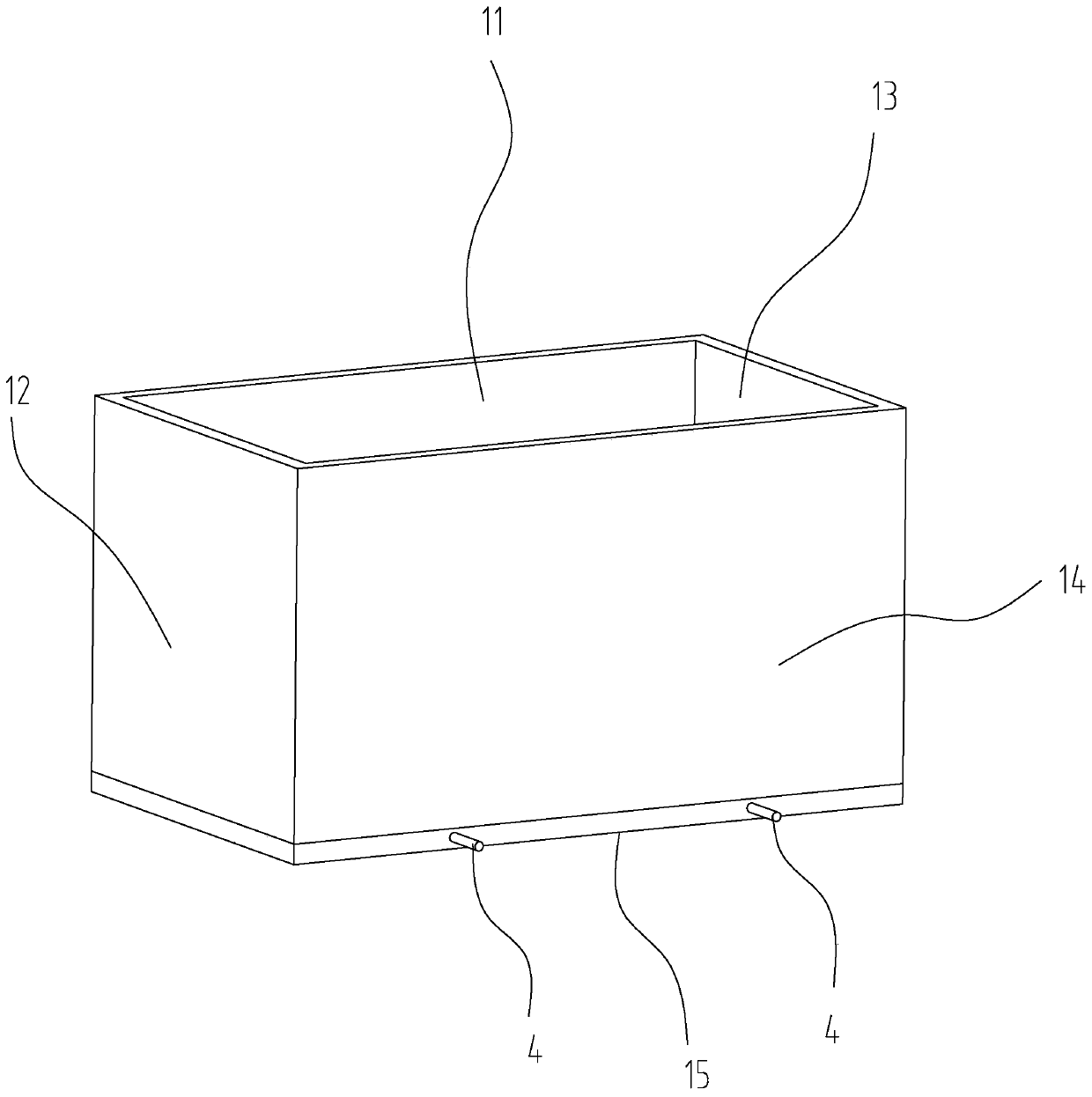

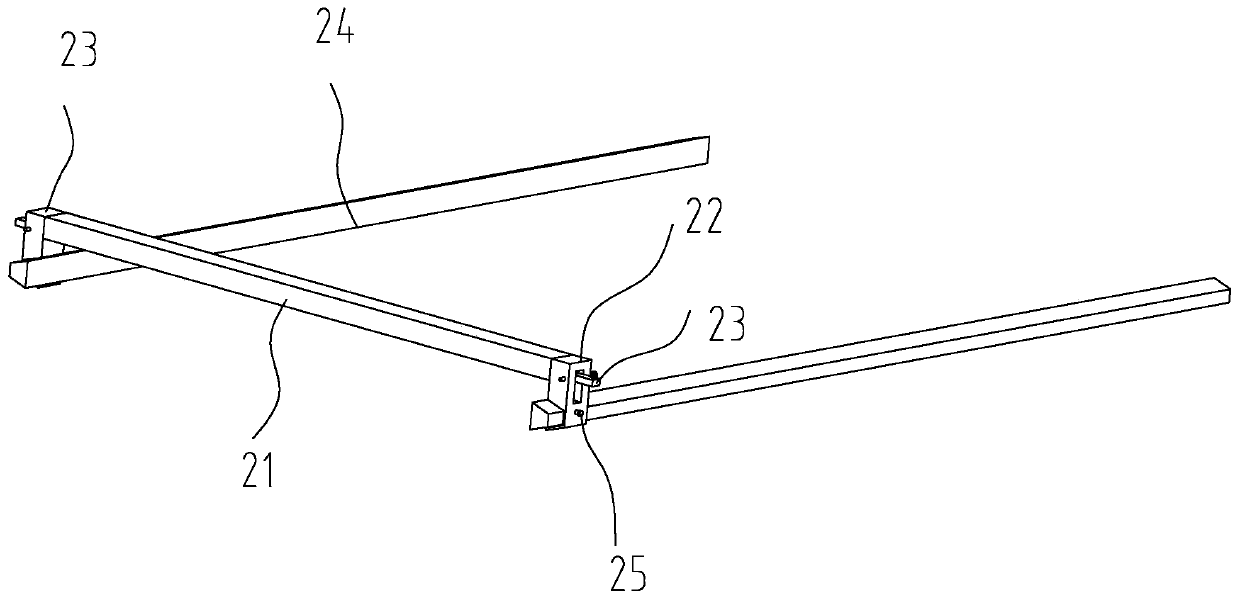

[0030] In order to clearly illustrate the technical characteristics of this program, the following specific implementation methods, combined with its attached Figures 1 to 11 , the present invention is described in detail. It should be noted that components illustrated in the figures are not necessarily drawn to scale. The present invention omits descriptions of well-known components and well-known technologies in order to avoid unnecessarily limiting the present invention.

[0031]An iron filings storage box in a factory, including a box body 1, an iron filings laying device 2, a lifting piece 3, a hanging rod 4, a foot-operated opening device 5 and a telescopic walking device 6; the box body 1 includes a front Side plate 11, left side plate 12, right side plate 13, back side plate 14 and lower cover 15, left side plate 12 is fixed on the left side of front side plate 11, and right side plate 13 is fixed on the right side of front side plate 12 , the rear side of the front...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com