Improved type perforated brick auxiliary cement mortar paver

A technology of perforated brick and mortar spreader, which is applied in construction, building structure, processing of building materials, etc., can solve the problems of falling cement mortar and cement mortar waste, avoiding waste, easy operation and strong practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In this embodiment, an eight-hole sintered clay brick is used as the specific implementation object of the technical solution of the patent.

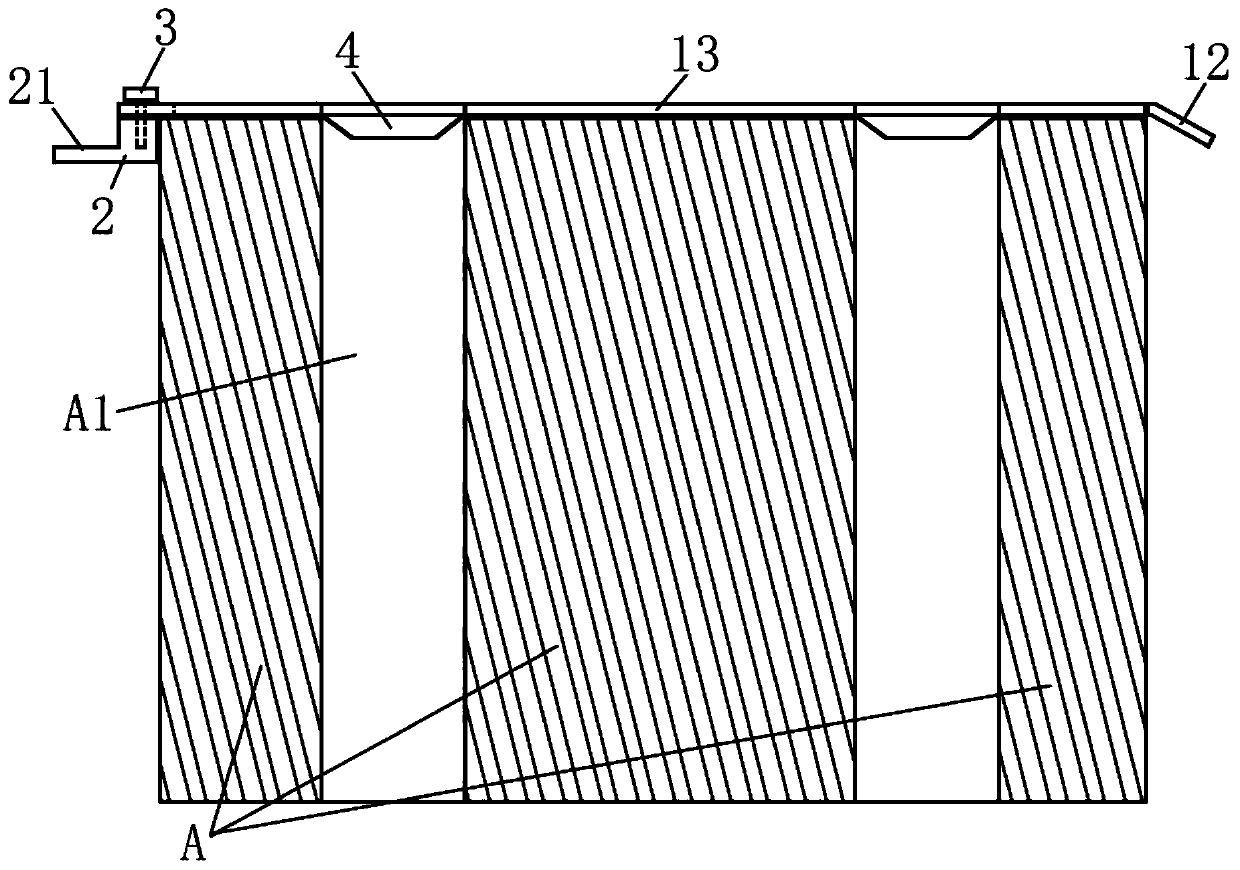

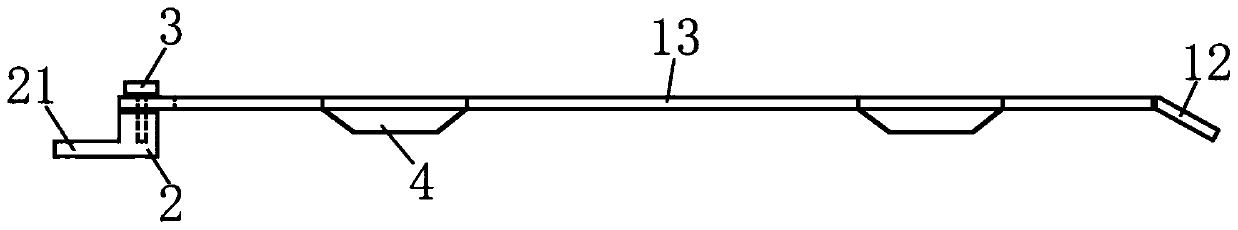

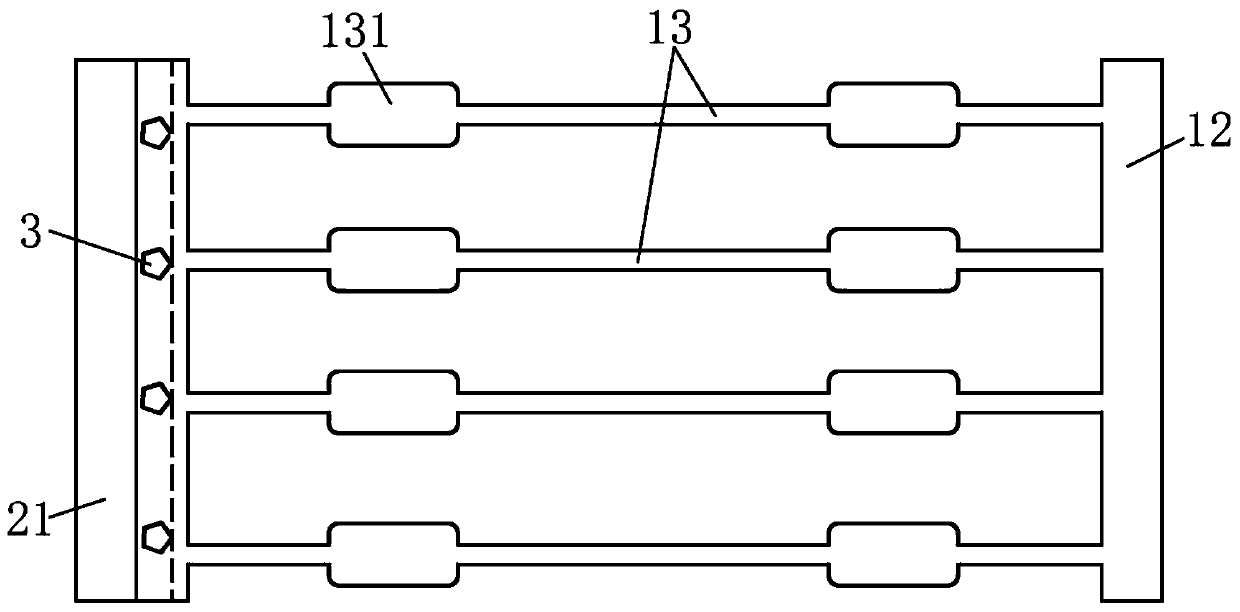

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, an improved auxiliary spreader for porous bricks is composed of a handle bar 2, a tightening screw 3, a die, and a sponge block 4. It is characterized in that:

[0025] The die is formed by stamping at one time. The die includes the front piece 11, the back piece 12, and 2 to 8 connecting strips 13. The 2 to 8 connecting strips 13 are pulled apart in parallel with each other. The front ends of the four connecting strips 13 are all aligned with the front The sheet 11 is connected, the rear ends of the four connecting strips 13 are all connected with the back sheet 12, the back sheet 12 is inclined downward, and the inclination angle of the back sheet 12 is 25°~45°;

[0026] The front piece 11 is integrally formed with 4 screw holes 111 by stamping;

[0027] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com