Construction method for remained gateway along goaf under metal false roof beside coal pillar

A construction method and coal pillar technology, which is applied in the direction of earth cube drilling, underground chambers, pillars/supports, etc., can solve problems such as the inability to guarantee the pouring space of flexible molded concrete walls, achieve good support effects, improve deformation problems, and improve roadway The effect of deformation stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings. Wherein the same components are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions towards or away from the geometric center of a particular part, respectively.

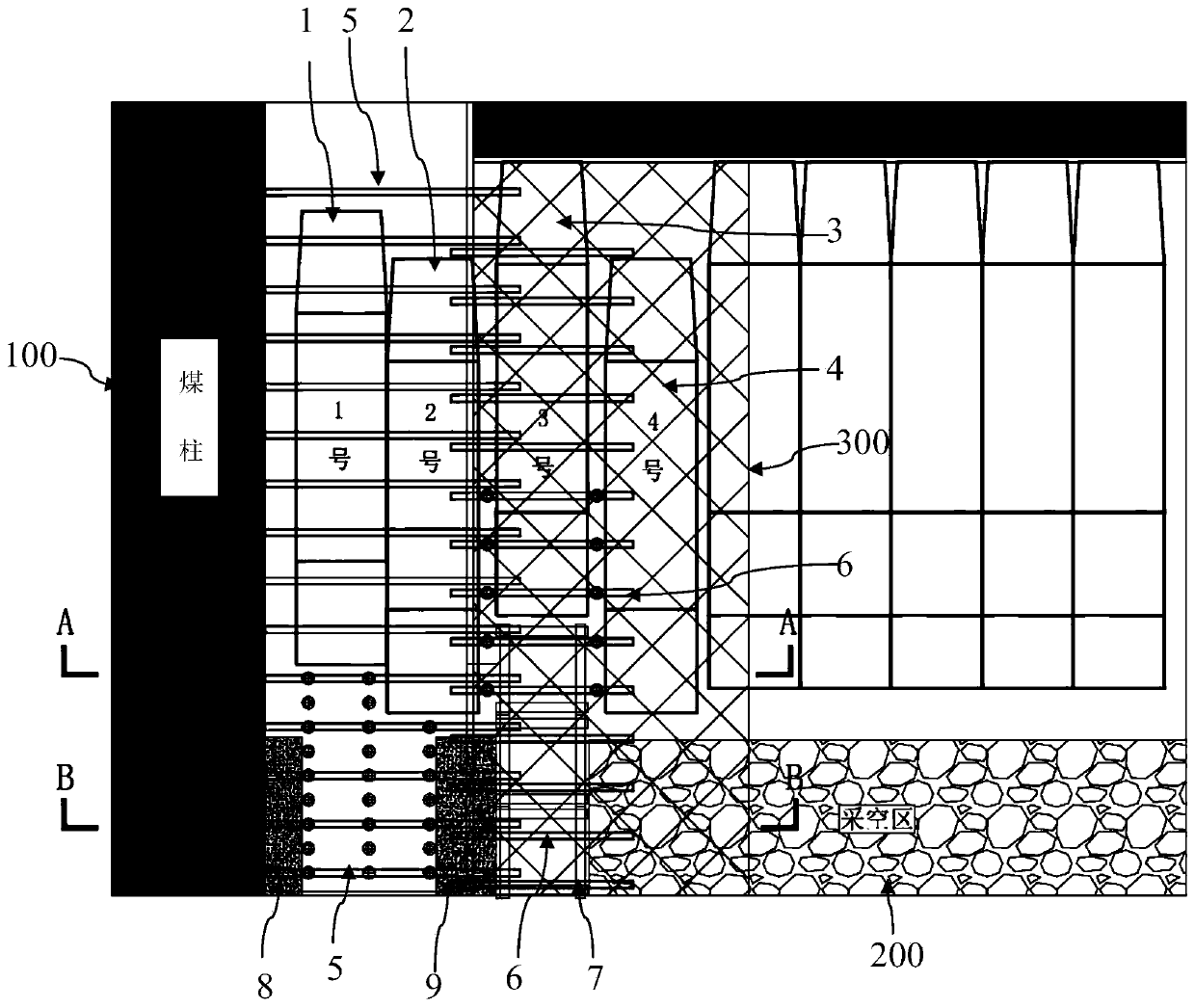

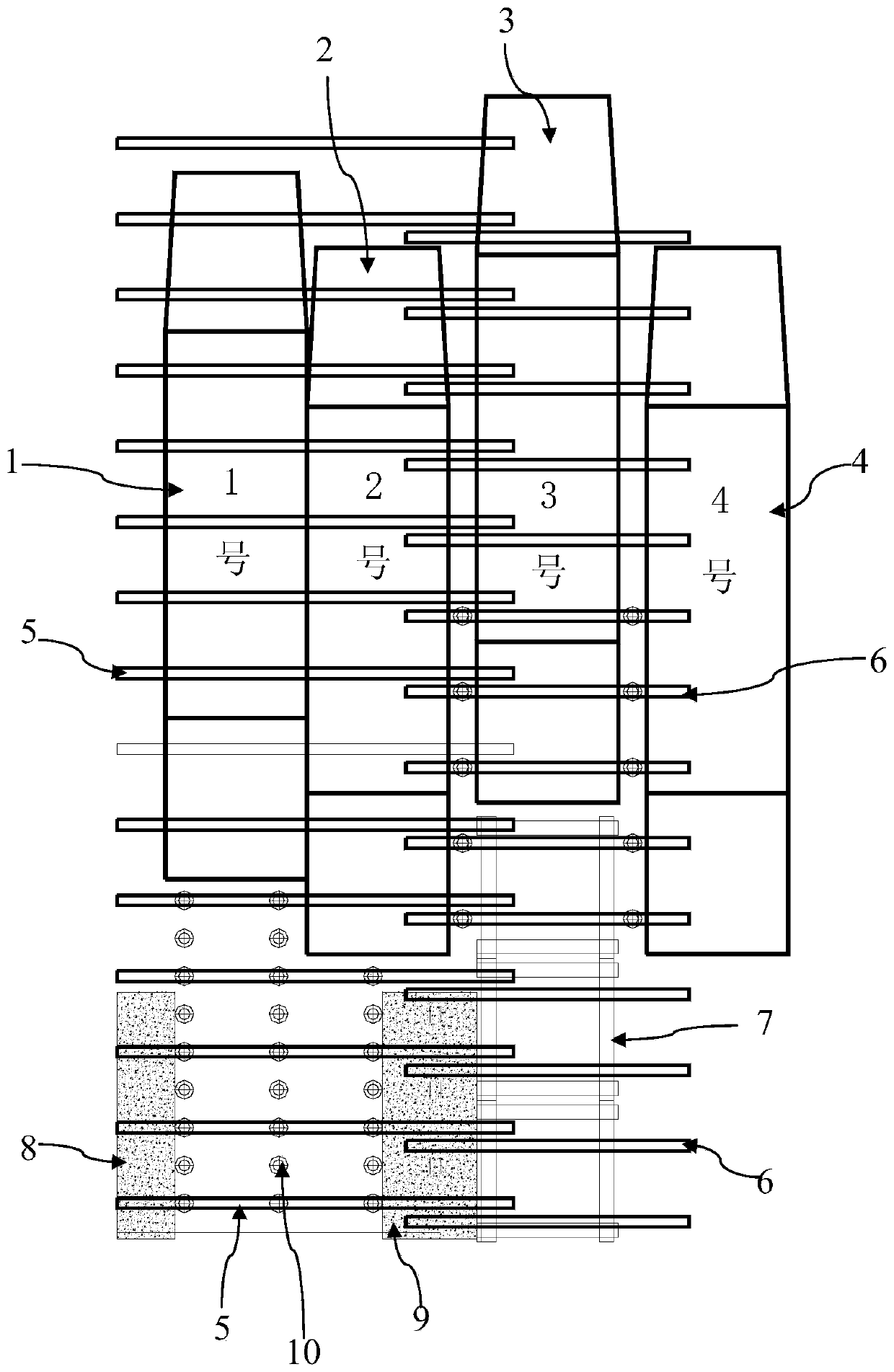

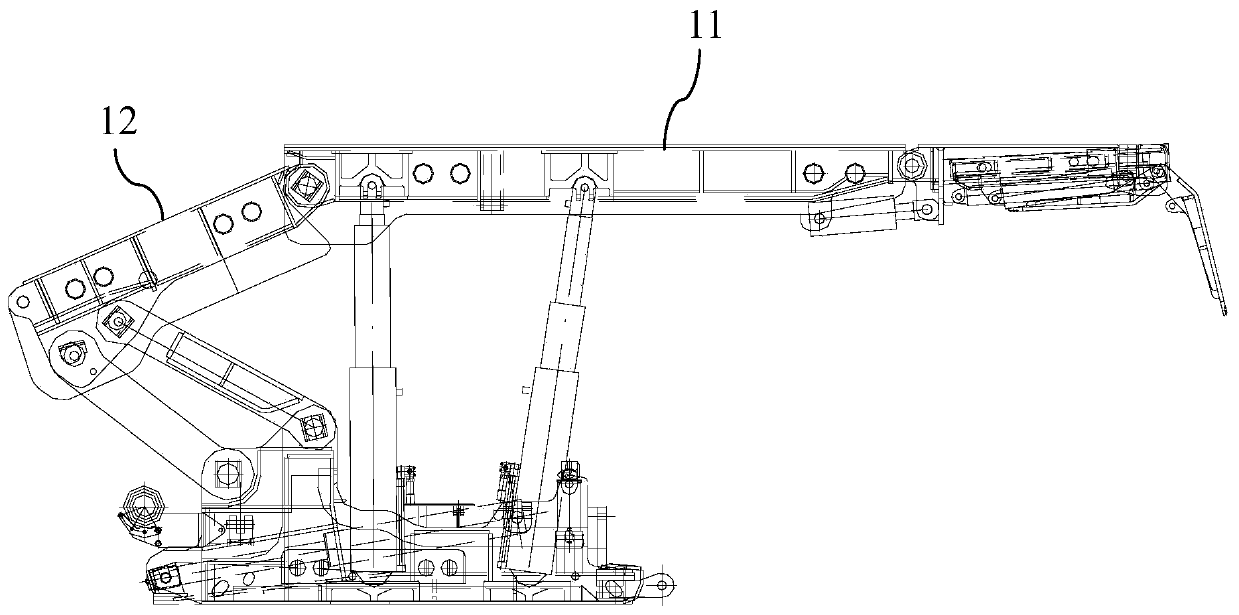

[0039] Such as Figure 1-5 As shown, the construction method for gob-side entry retention under the metal false roof next to the coal pillar provided by an embodiment of the present invention includes the following steps:

[0040] S001: Arrange the first hydraulic support 1 , the second hydraulic support 2 , the third hydraulic support 3 and the fourth hydraulic support 4 on the working face in sequence along the direction from the coal pillar 100 to the gob 200 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com