Method for making vertical wood structure thin plate and composite floor

A manufacturing method and wood structure technology, which is applied in the jointing of wooden veneers, wood layered products, chemical instruments and methods, etc., can solve the problems of losing the unique properties of wood, high material cost, easy deformation, etc., and achieve improved deformation Problems, stable physical performance, and the effect of solving deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

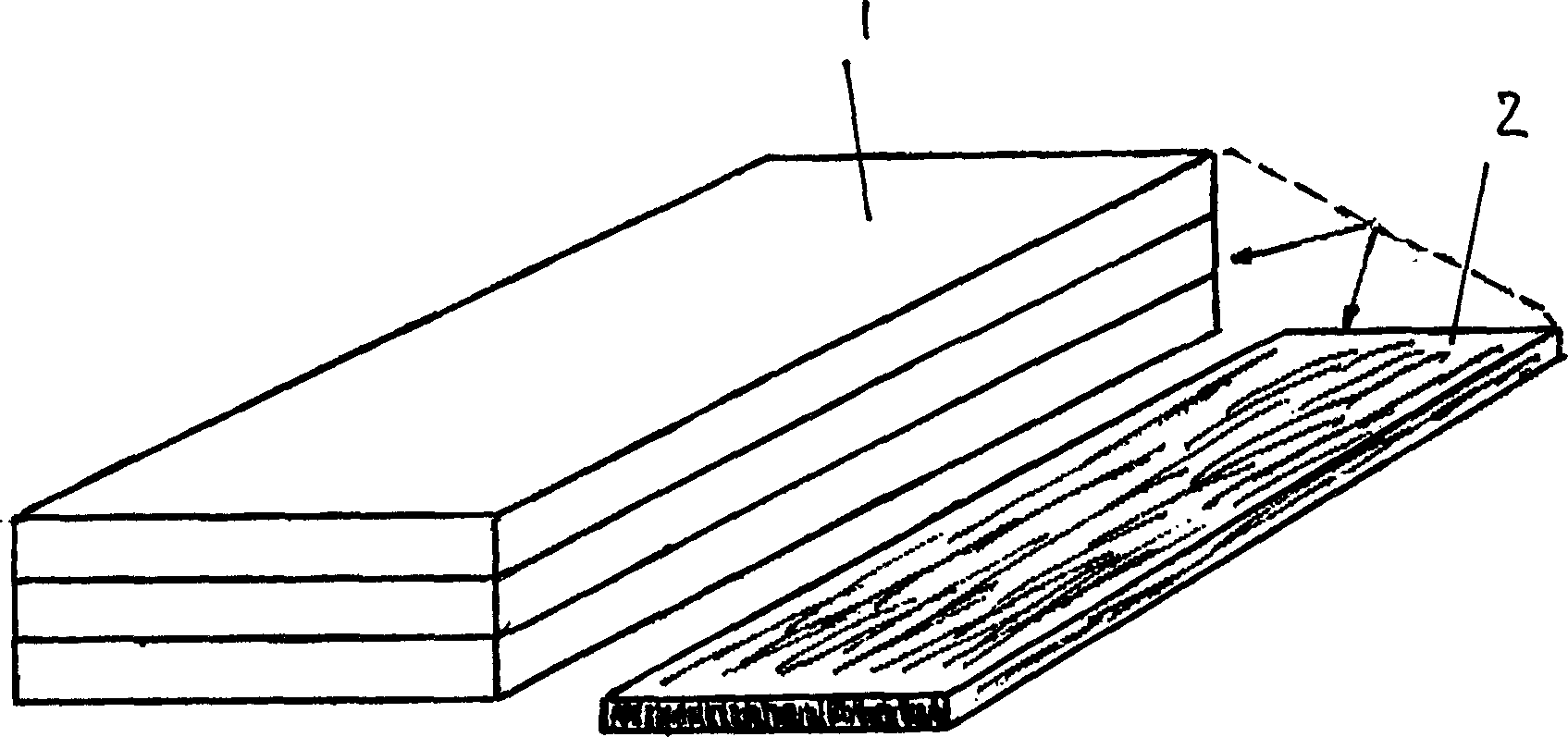

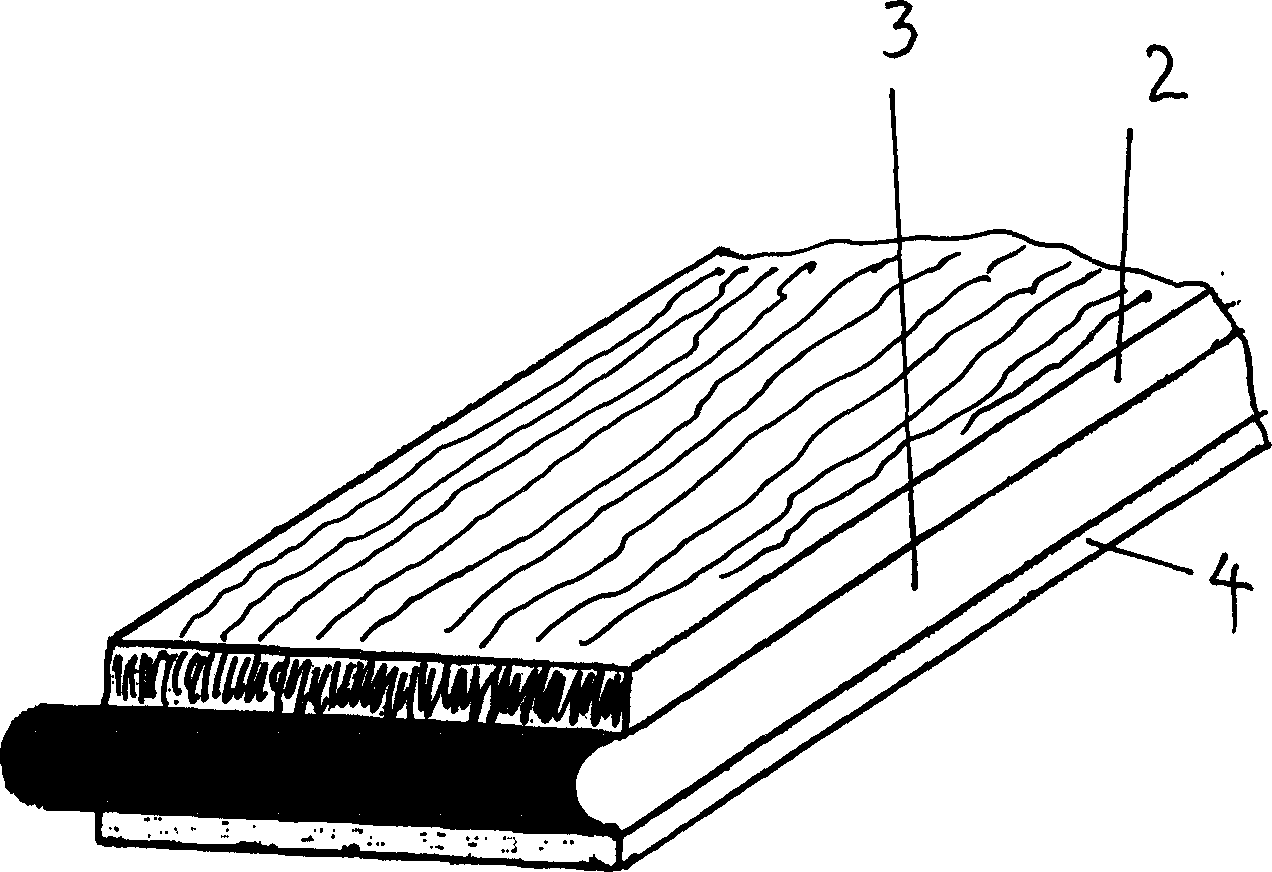

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings: the present invention is mainly formed by splicing at least three layers of boards, that is, it includes at least an intermediate layer, a panel layer and a bottom board. Among them, the panel layer is a thin board layer of standing timber structure glued together by multiple veneers in sequence, see attached figure 1 shown. The preparation of the standing log structure veneer is as follows: firstly, the wood is cut into veneer sheets with different sizes, lengths or thicknesses, and the two sides of the veneer sheets are glued to form irregular blanks. After the billet is formed, the billet 1 is cold-pressed to the required thickness, and then the billet 1 is sawn along the length direction to form a wooden structure veneer 2, and the sawn surface is used as the front.

[0010] figure 2 As shown, the composite flooring of the present invention is mainly composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com