A superabrasive grinding wheel for grinding fingerprint recognition lock substrate and preparation method thereof

A technology of fingerprint recognition locks and superhard abrasives, which is applied in the direction of grinding/polishing equipment, abrasives, grinding devices, etc., can solve the problems of low yield rate, low process efficiency, and many substrate processing procedures, and achieve low strength and high Effect of surface finish, low thickness deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The soft elastic matrix with medium and low elastic modulus includes calcium sulfate whiskers, carbon fibers, copper-tin-titanium alloy powder, bakelite powder, polyimide resin powder, and is composed of the following parts by weight: 10 parts of calcium sulfate whiskers, carbon fiber 10 parts, copper-tin-titanium alloy 2 parts, bakelite powder 5 parts, polyimide resin powder 35 parts.

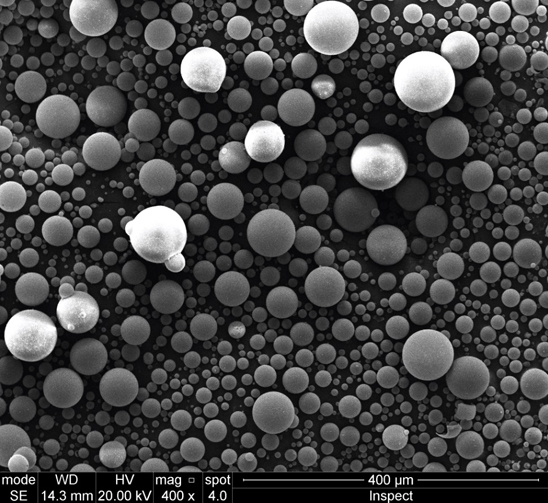

[0041] The superhard abrasive is single crystal diamond, the functional filler is silica hollow spheres, phenol novolac epoxy acrylate, and dextrin, the resin binder is foamed modified phenolic resin, and the superhard abrasive The shaved layer includes the following raw materials in parts by weight: 5 parts of single crystal diamond, 30 parts of hollow silicon dioxide spheres, 30 parts of phenol novolac epoxy acrylate, 15 parts of dextrin, and 25 parts of phenolic resin solution.

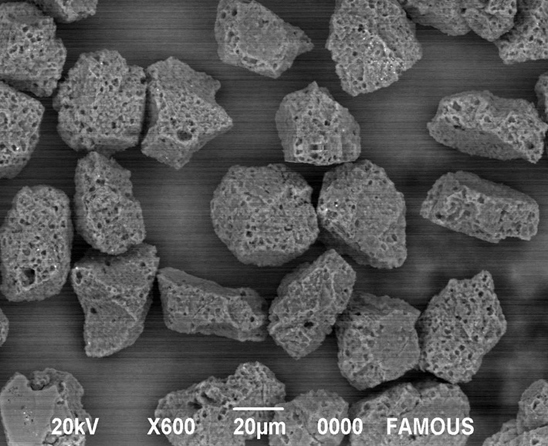

[0042] The single crystal diamond is selected from particles with a particle size in the range of 10-20 μ...

Embodiment 2

[0045] The soft elastic matrix with medium and low elastic modulus includes calcium sulfate whiskers, carbon fibers, copper-tin-titanium alloy powder, bakelite powder, polyimide resin powder, and is composed of the following parts by weight: 20 parts of calcium sulfate whiskers, carbon fiber 20 parts, copper-tin-titanium alloy 5 parts, bakelite powder 15 parts, polyimide resin powder 40 parts.

[0046] The superhard abrasive is single crystal diamond, the functional filler is silica hollow spheres, phenol novolac epoxy acrylate, and dextrin, the resin binder is foamed modified phenolic resin, and the superhard abrasive The shaved layer includes the following raw materials in parts by weight: 7.5 parts of single crystal diamond, 32 parts of hollow silicon dioxide spheres, 28 parts of phenol novolac epoxy acrylate, 16 parts of dextrin, and 16.5 parts of phenolic resin solution.

[0047] The single crystal diamond is selected from particles with a particle size in the range of 20...

Embodiment 3

[0050] The soft elastic matrix with medium and low elastic modulus includes calcium sulfate whiskers, carbon fibers, copper-tin-titanium alloy powder, bakelite powder, polyimide resin powder, and is composed of the following parts by weight: 30 parts of calcium sulfate whiskers, carbon fiber 10 parts, copper-tin-titanium alloy 5 parts, bakelite powder 10 parts, polyimide resin powder 50 parts.

[0051] The superhard abrasive is single crystal diamond, the functional filler is silica hollow spheres, phenol novolac epoxy acrylate, and dextrin, the resin binder is foamed modified phenolic resin, and the superhard abrasive The shaving layer includes the following raw materials in parts by weight: 10 parts of single crystal diamond, 34 parts of hollow silicon dioxide spheres, 26 parts of phenol novolac epoxy acrylate, 17 parts of dextrin, and 13 parts of phenolic resin solution.

[0052] The single crystal diamond is selected from particles with a particle size in the range of 25-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com