Environment-friendly light paste scraping device

A lightweight and environmentally friendly technology, applied in rotary printing presses, printing, printing presses, etc., can solve the problems of large size, high labor intensity and inconvenient operation of the scraper of the printing machine, and achieve good printing color and small color paste capacity. , the effect of less waste of color paste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

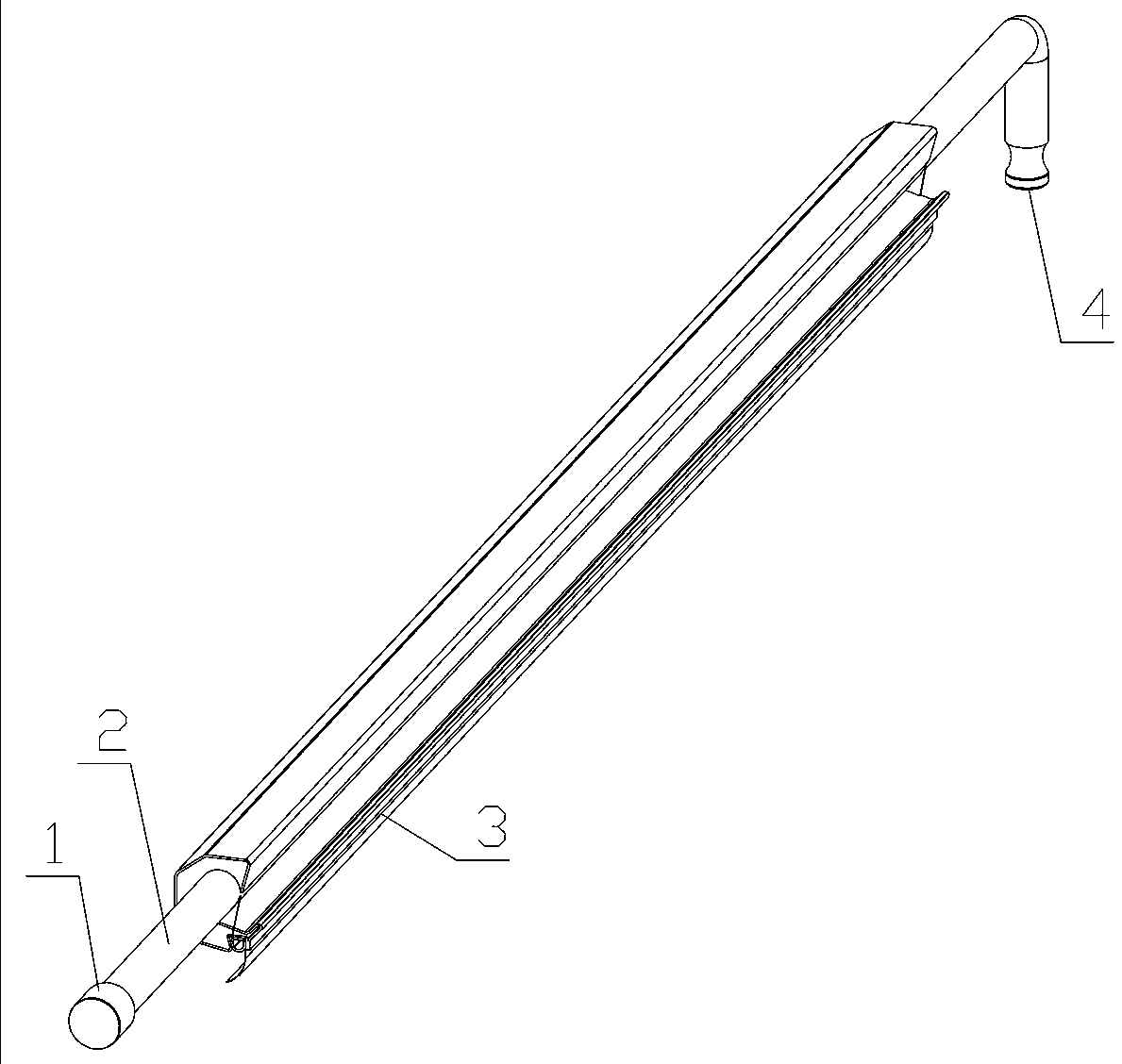

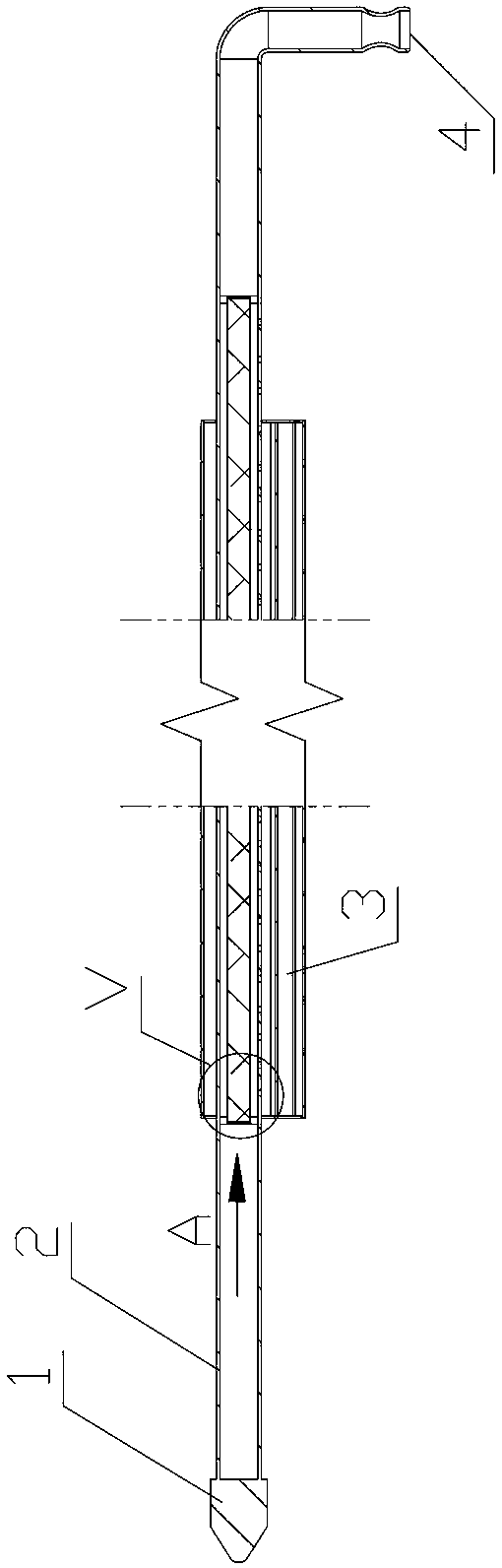

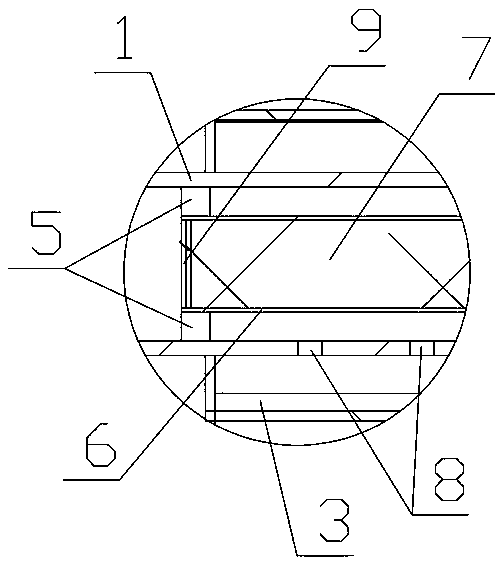

[0013] see Figure 1-4 , this embodiment includes a stainless steel pipe 2, one end of the stainless steel pipe 2 is provided with a slurry inlet 4, the other end is provided with a removable plug 1, the bottom of the stainless steel pipe 2 is provided with a scraper 3, and the bottom of the stainless steel pipe 2 is provided with a scraper There are several slurry holes 8 in the length direction of 3, and a reinforcing pipe 6 is installed in the stainless steel pipe 2. The length of the reinforcing pipe 6 is greater than the length of the scraper 3, and the two ends of the reinforcing pipe 6 exceed the two ends of the scraper 3 respectively. The outer wall of the reinforcing pipe 6 is connected with the inner wall of the stainless steel pipe 2 through the bracket 5 , the two ends of the reinforcing pipe 6 are provided with sealing plates 9 , and the reinforcing pipe 6 is filled with foam glue 7 .

[0014] The thickness of the pipe wall of the reinforcing pipe 6 in this embodi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com