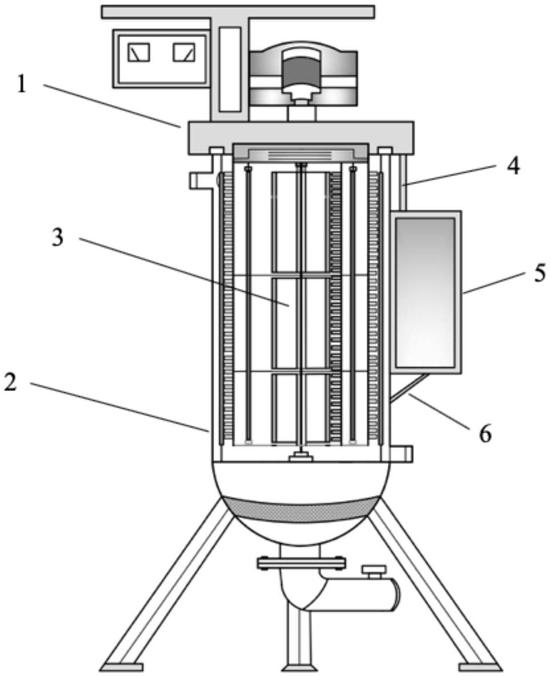

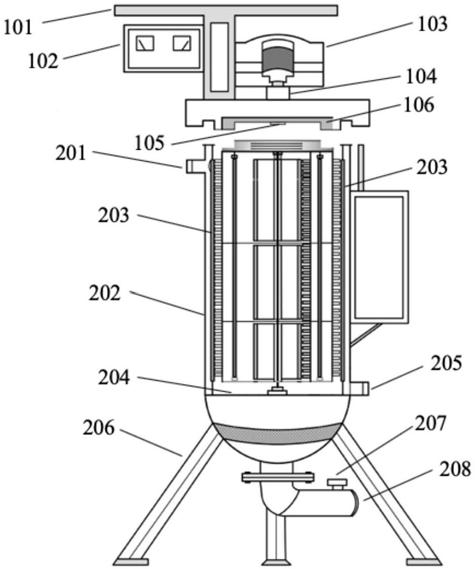

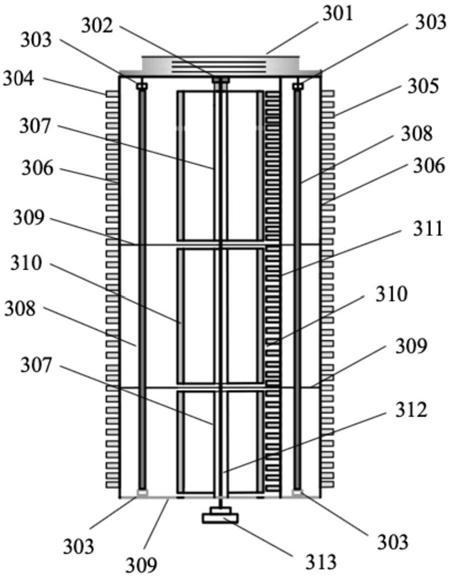

A modular electrochemical device for automatic rotation and efficient chlorine and scale removal

An automatic rotation, electrochemical technology, applied in electrochemical water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve problems such as high cost, incomplete descaling, cumbersome descaling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0033] When the electrochemical reaction is running normally, when the chlorine ion concentration of the influent is 56mg / L, the hardness is 6800mg / L (methyl orange hardness, calculated as CaCO3), when the hydraulic retention time is 5min, the plate current density is 8mA / cm2 , the concentration of chloride ion in the single reaction effluent is 32mg / L, the hardness is lower than 2000mg / L, and the removal efficiency reaches 43.0% and 70.5% respectively.

[0034] Groundbreakingly, the arc-shaped corrosion-resistant anode sheet of the present invention is stable and corrosion-resistant, and each system is convenient to disassemble and replace, and the descaling method is simple and efficient.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com