Redissolution supplementary salt, nitrate and salt separation system and process for zero discharge of desulfurization wastewater

A desulfurization wastewater, zero discharge technology, applied in the direction of gaseous effluent wastewater treatment, centrifugal separation water/sewage treatment, alkali metal sulfite/sulfate purification, etc. It can achieve the effects of ensuring stable and long-term operation, eliminating adverse effects, and reducing equipment investment due to problems such as less than the emission standard and large amount of solid impurity salt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Embodiments of the technology will be further described below in conjunction with the accompanying drawings:

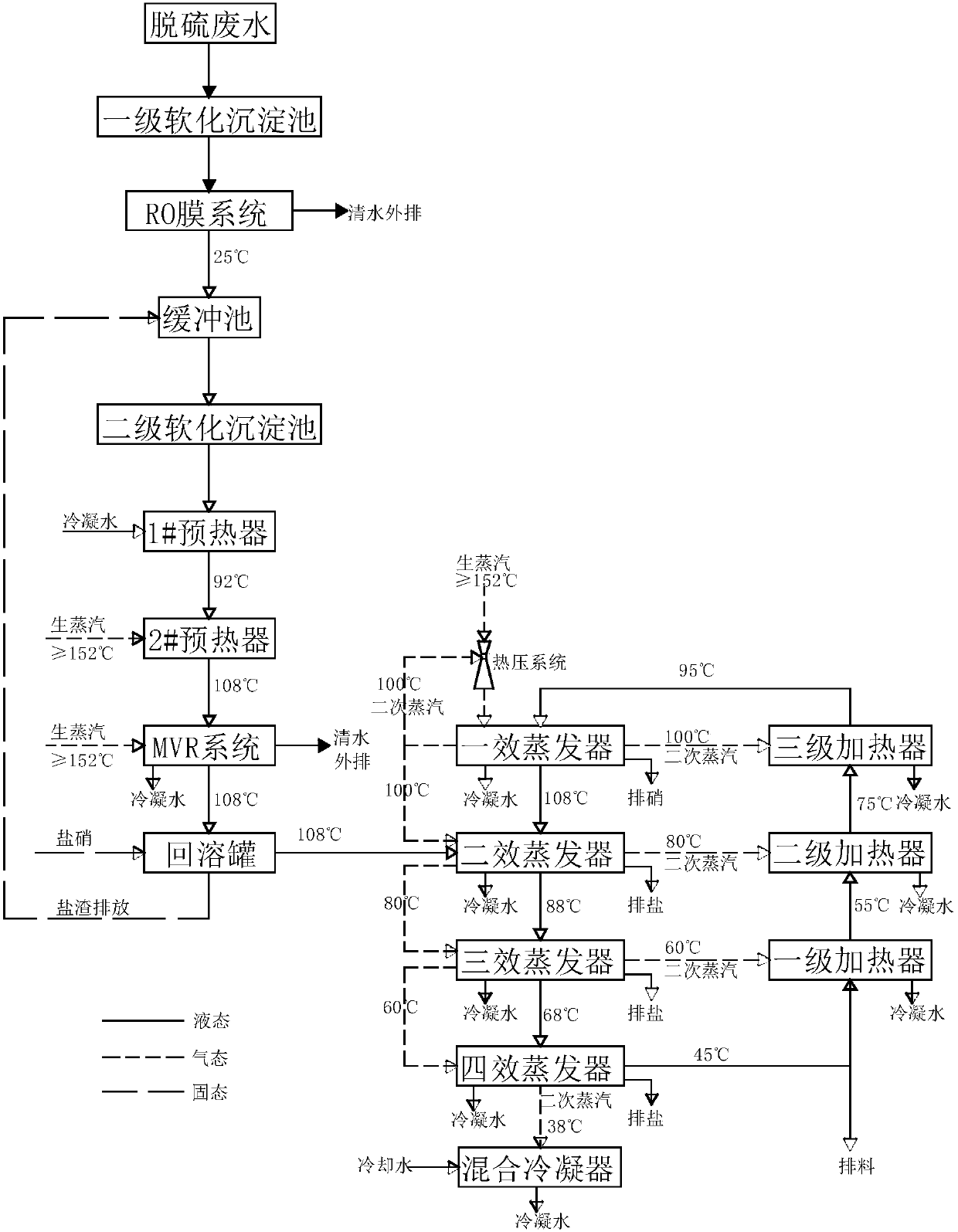

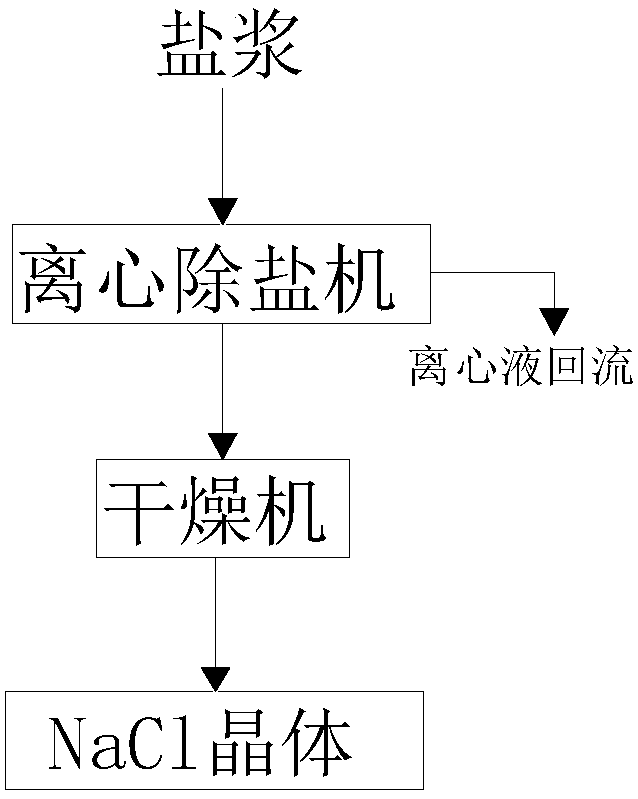

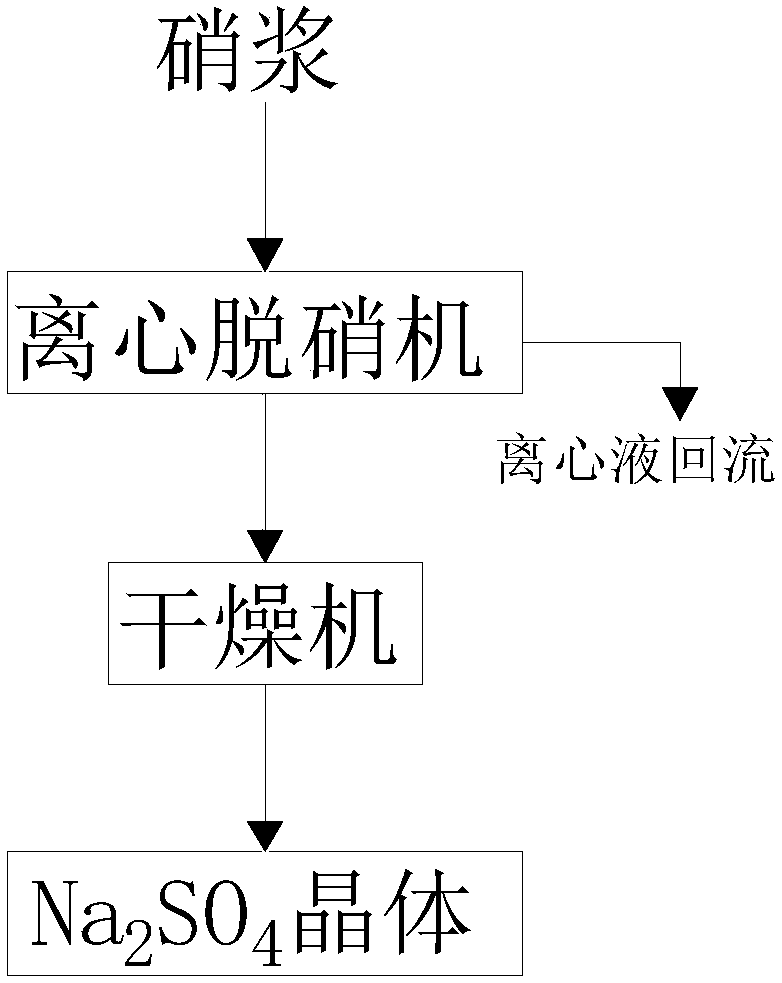

[0031] A specific example of this technology is figure 1 As shown, including primary softening sedimentation tank, double membrane system, buffer tank, secondary softening sedimentation tank, 1# preheater, 2# preheater, MVR system, remelting tank, first effect evaporator, second effect evaporation It is composed of evaporator, three-effect evaporator, four-effect evaporator, mixed condenser, first-stage heater, second-stage heater, third-stage heater, hot-press system, centrifugal desalination system and centrifugal nitrate system.

[0032] The specific implementation process includes the following steps:

[0033] (1) Desulfurization wastewater at 25°C undergoes primary softening and precipitation to remove pollutants such as miscellaneous salts and heavy metals, and then enters the double-membrane concentration system. The RO membrane clear liquid is discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com