Rotary etching device and rotary etching method for high-precision ultrathin glass

A technology of ultra-thin glass and etching device, which is applied in the field of high-precision ultra-thin glass rotary etching device, which can solve problems such as low surface quality and increased thickness deviation, and achieve the effect of improving fingerprint recognition performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

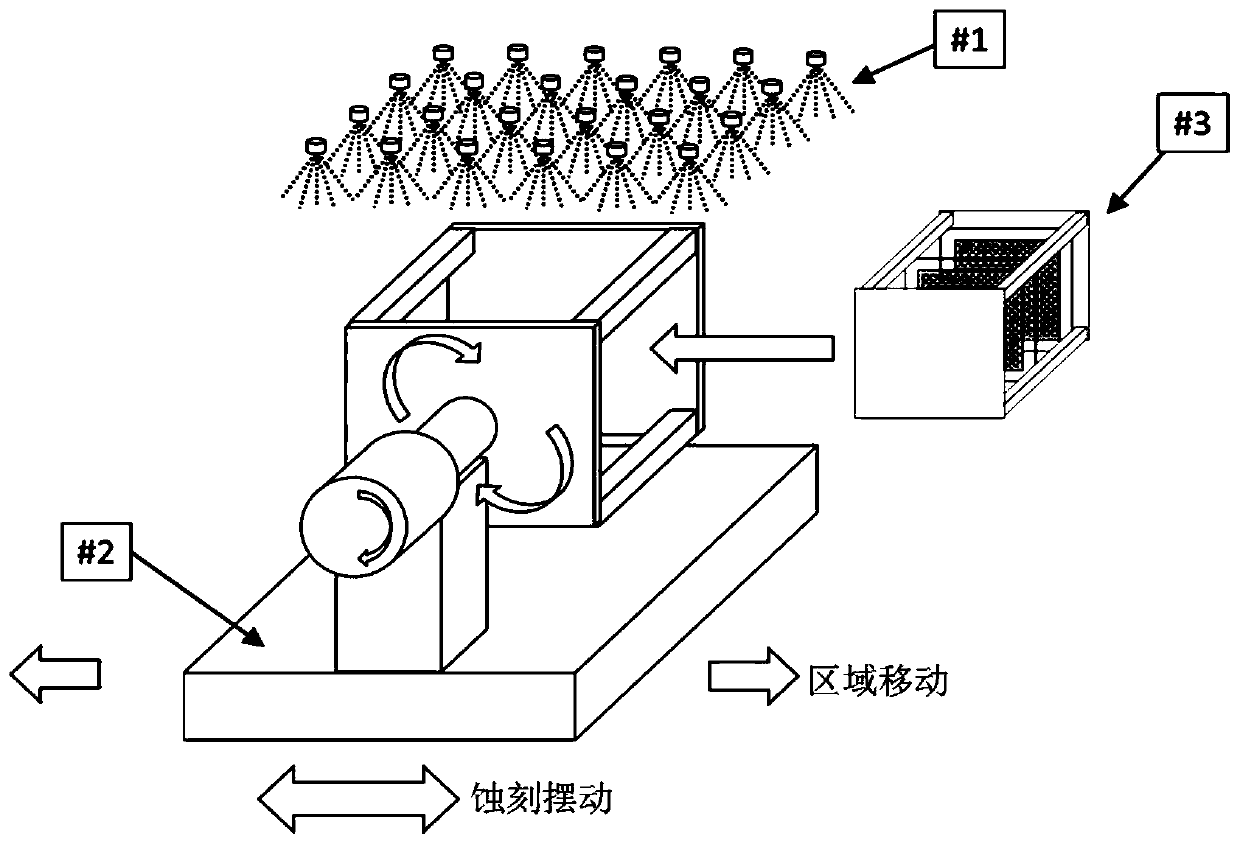

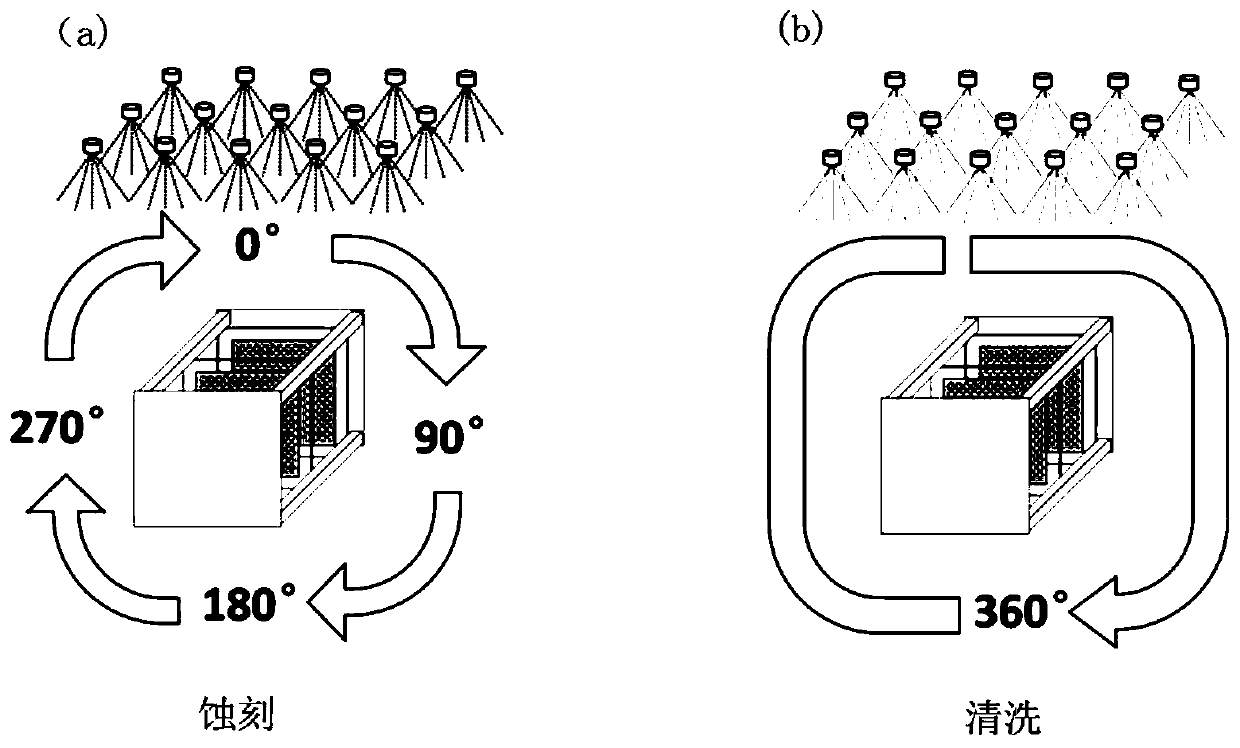

[0052] Figure 4 A schematic diagram showing a process description of a spin etching method for high-precision ultra-thin glass according to an exemplary embodiment of the present invention,

[0053] Such as Figure 4 As shown, the basket with several fixtures (with glass substrates) fixed in the rotatable fixed frame of the CST tray is rotated in the etching area or cleaning area where the etching solution or cleaning solution is sprayed from the top, so that the The glass substrate is etched to less than 0.1mm to produce high-precision ultra-thin glass, which is suitable for the manufacture of foldable mobile phones, rollable mobile phones, cover glass for OLED lighting, and substrates for OLED, TFT, and MicroLED.

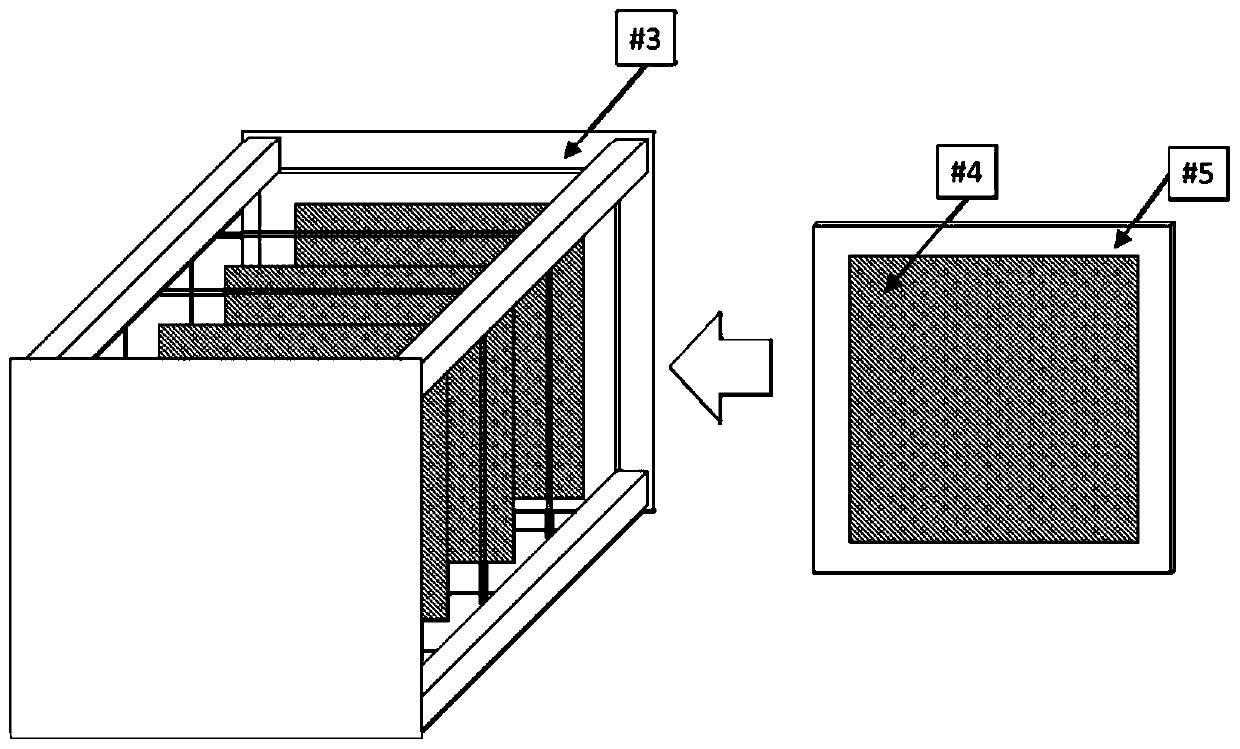

[0054] First, the jig #5 with the glass substrate #4 to be etched attached is inserted into the basket #3 and the jig is locked to prevent the jig from being separated or flowing out from the basket. Then install the basket on the rotatable fixed frame of the C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com