Construction method for high-level large-diameter directional drilling of complex roof

A technology of directional drilling and construction methods, applied in drilling equipment and methods, directional drilling, drill bits, etc., can solve the problem of increasing casing stiffness and casing weight, failure of casing running, and increasing the difficulty of casing running, etc. problems, to achieve the effect of reducing the difficulty of decentralization and ensuring smooth implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

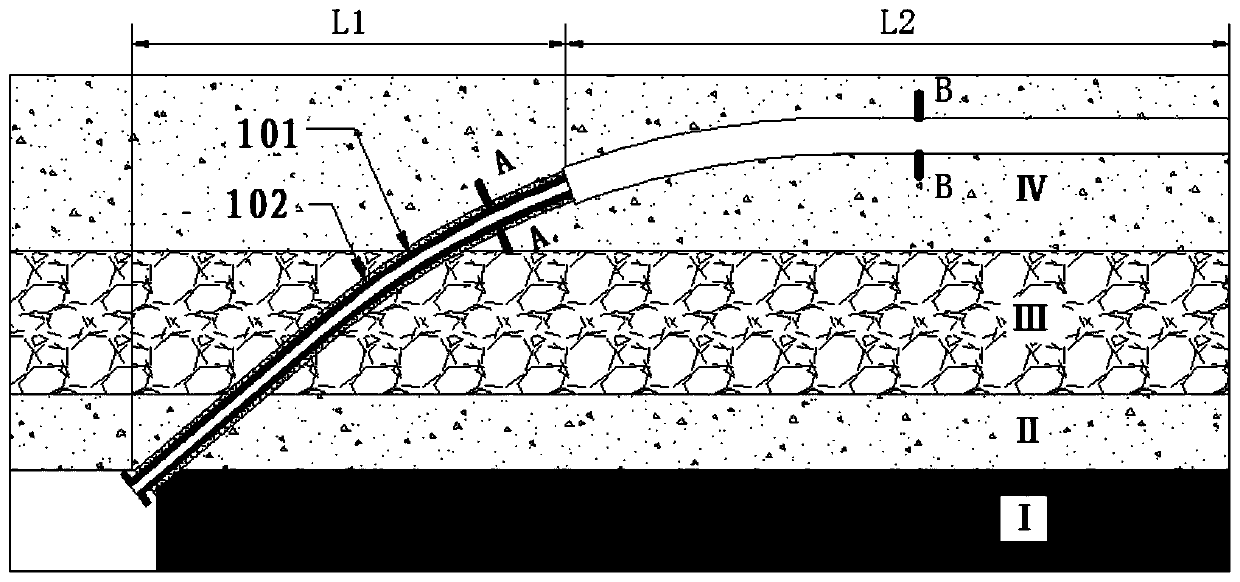

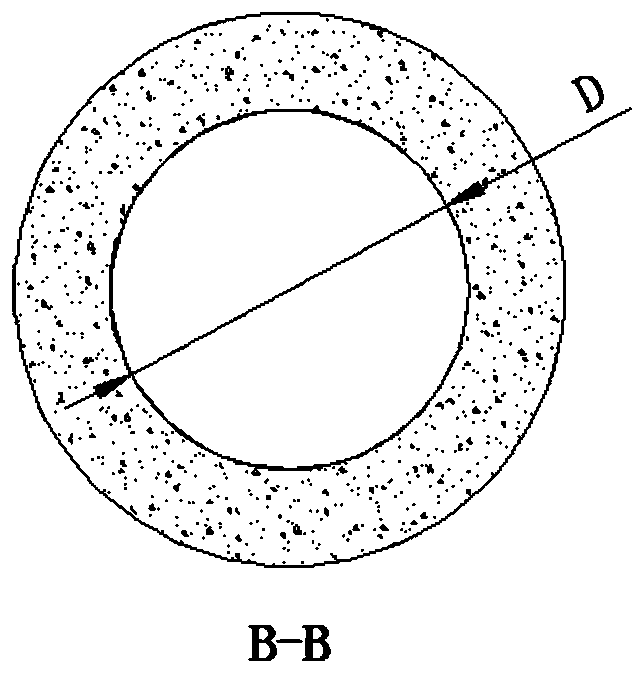

[0043] see figure 1 , shows a preferred embodiment of the high-position large-diameter directional drilling of the complex roof of the present invention, the complex top-plate high-position large-diameter directional drilling consists of casing hole section L 1 and main drainage hole section L 2 Composition, the main extraction hole section L 2 Arranged in the stable drainage layer IV, the casing hole segment L 1 From the coal seam I along an inclination, it enters the roof II, the weak and broken layer III and the stable drainage layer IV in turn, and connects to the main drainage hole section L after the stable drainage layer IV bends 2 .

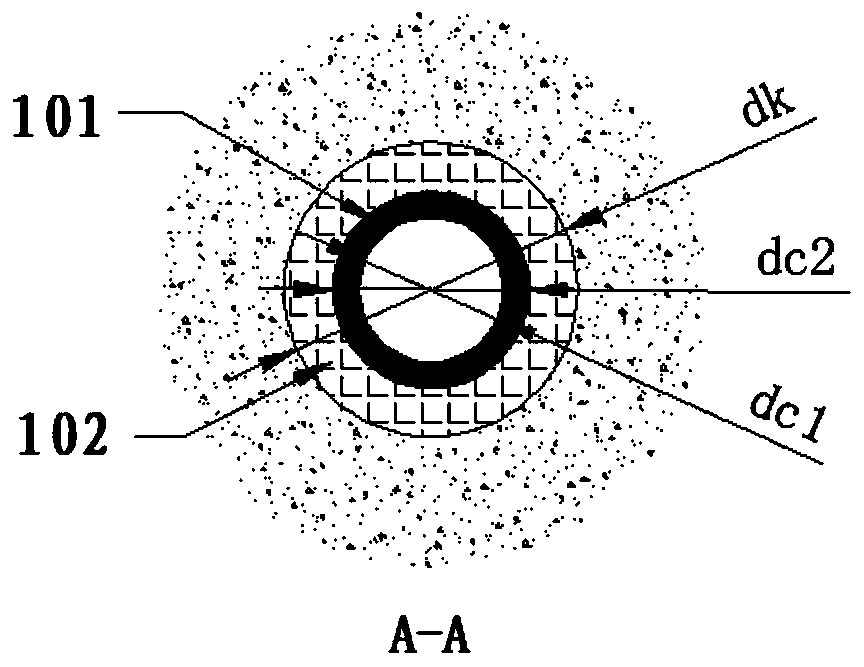

[0044] The casing hole section L 1 Into the protective wall casing 101, see also Figure 1A , the 101 inner diameter of the wall casing is d c1 , the outer diameter is d c2 , the casing hole segment L 1 The inner diameter is d K , the wall casing 101 and casing hole segment L 1 After the sealing material 102 is injected into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com