Current transformer experiment detection mechanism

A technology of current transformer and detection mechanism, which is applied in the parts, instruments, measuring electricity and other directions of electrical measuring instruments, can solve the problems of labor waste and low efficiency, and achieve the effect of improving efficiency and quality, high efficiency and eliminating harm.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

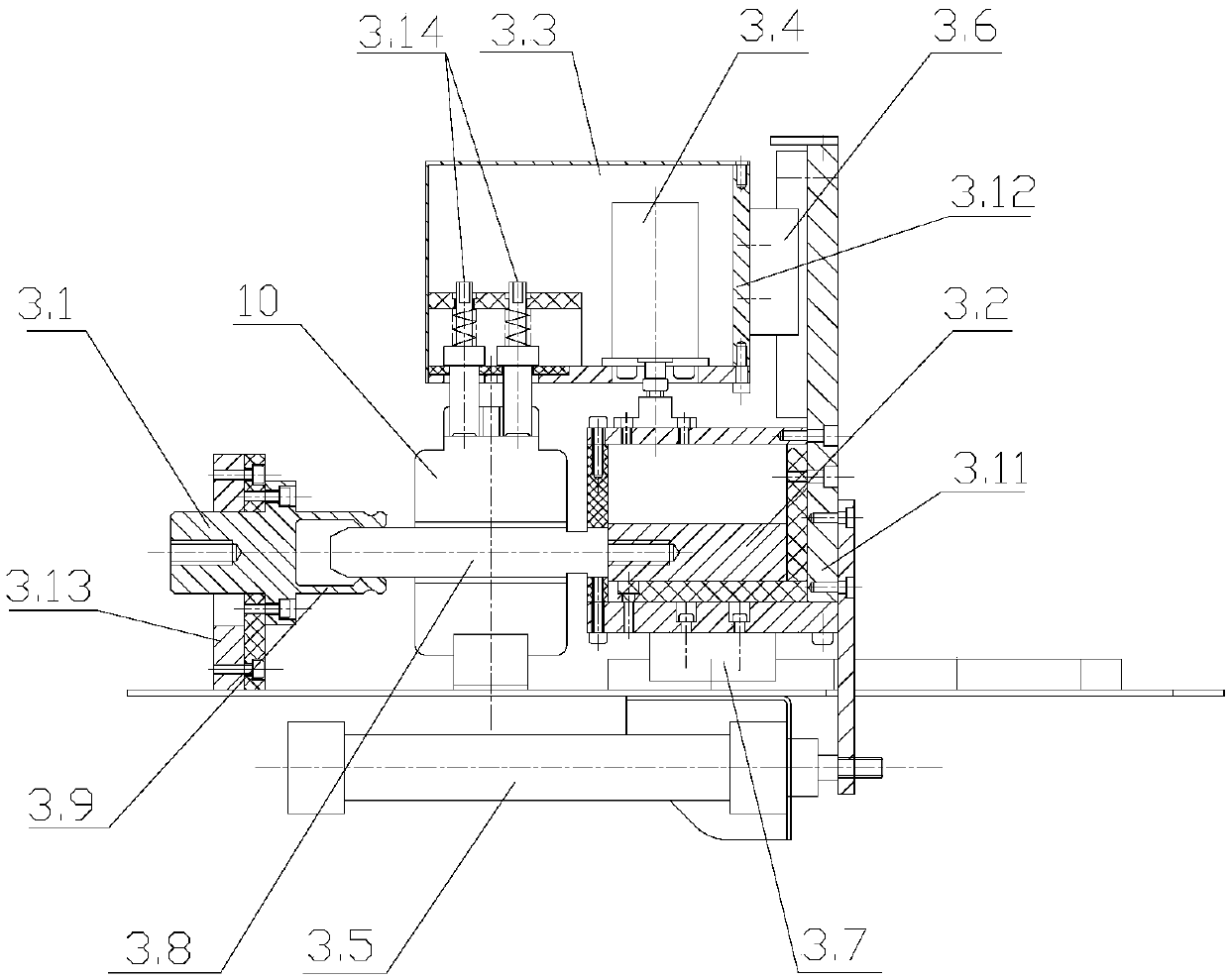

[0016] Such as figure 1 As shown, a current transformer experimental detection mechanism provided by the present invention includes a primary line fixed part 3.1, a primary line moving part 3.2 and a secondary line part 3.3, wherein the primary line fixed part 3.1 is fixedly connected to the frame, and the primary line moving part 3.2 can be slidably connected with the frame along the direction close to or away from the primary line fixed part 3.1, the primary line fixed part 3.1 is connected with the primary line fixed part 3.1 by sliding, and can be used as the primary conductive rod of the current transformer, and the secondary line part 3.3 is set on The primary wire moving part 3.2 is above and can be raised and lowered along the Z-axis direc...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap