Transparent projection film

A technology of projection film and transparent film, applied in optics, instruments, projection devices, etc., can solve problems such as difficult processing and production, projection screen stays in the theoretical stage, and limited improvement of projection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following examples are further explanations and supplements to the present invention, and do not constitute any limitation to the present invention.

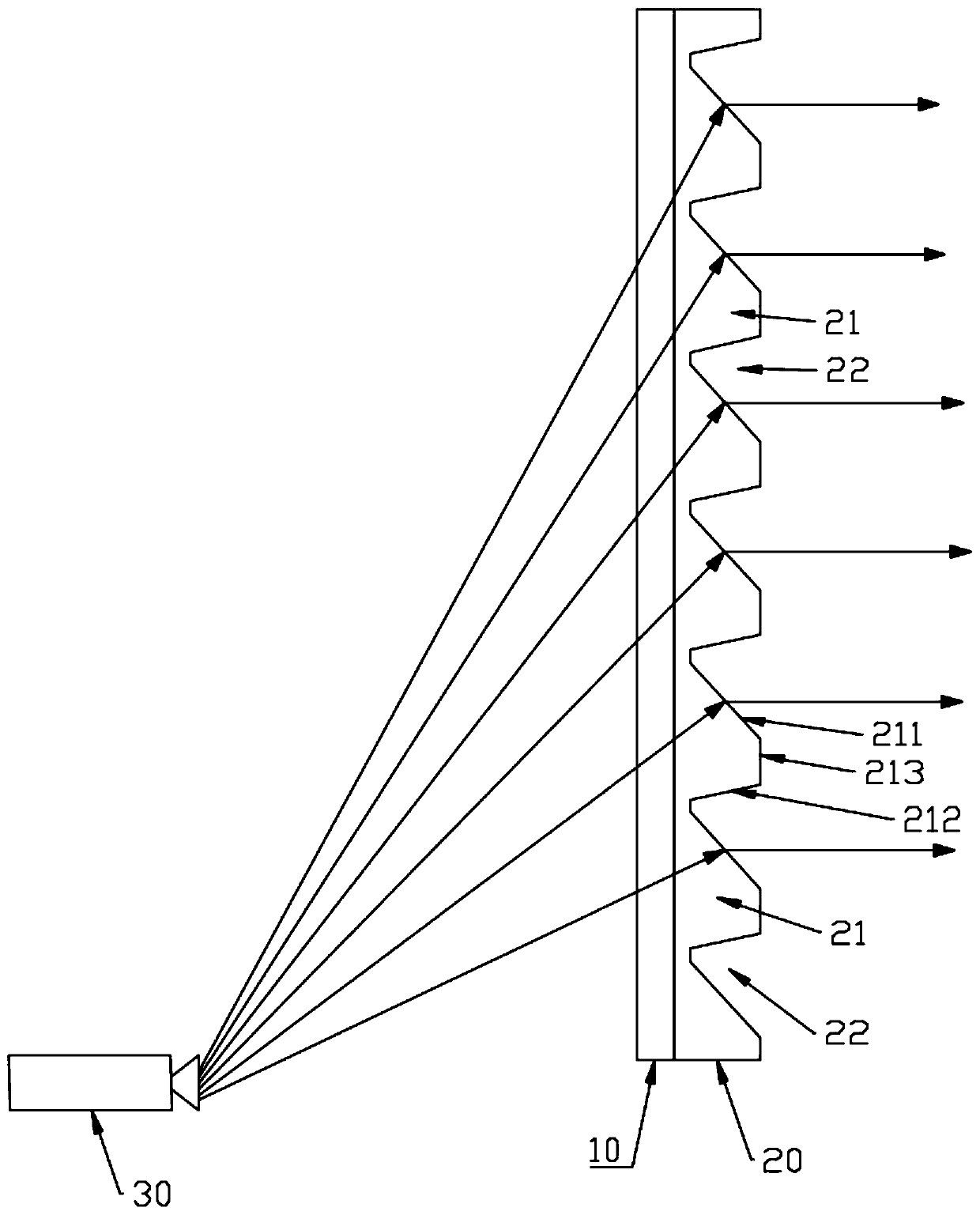

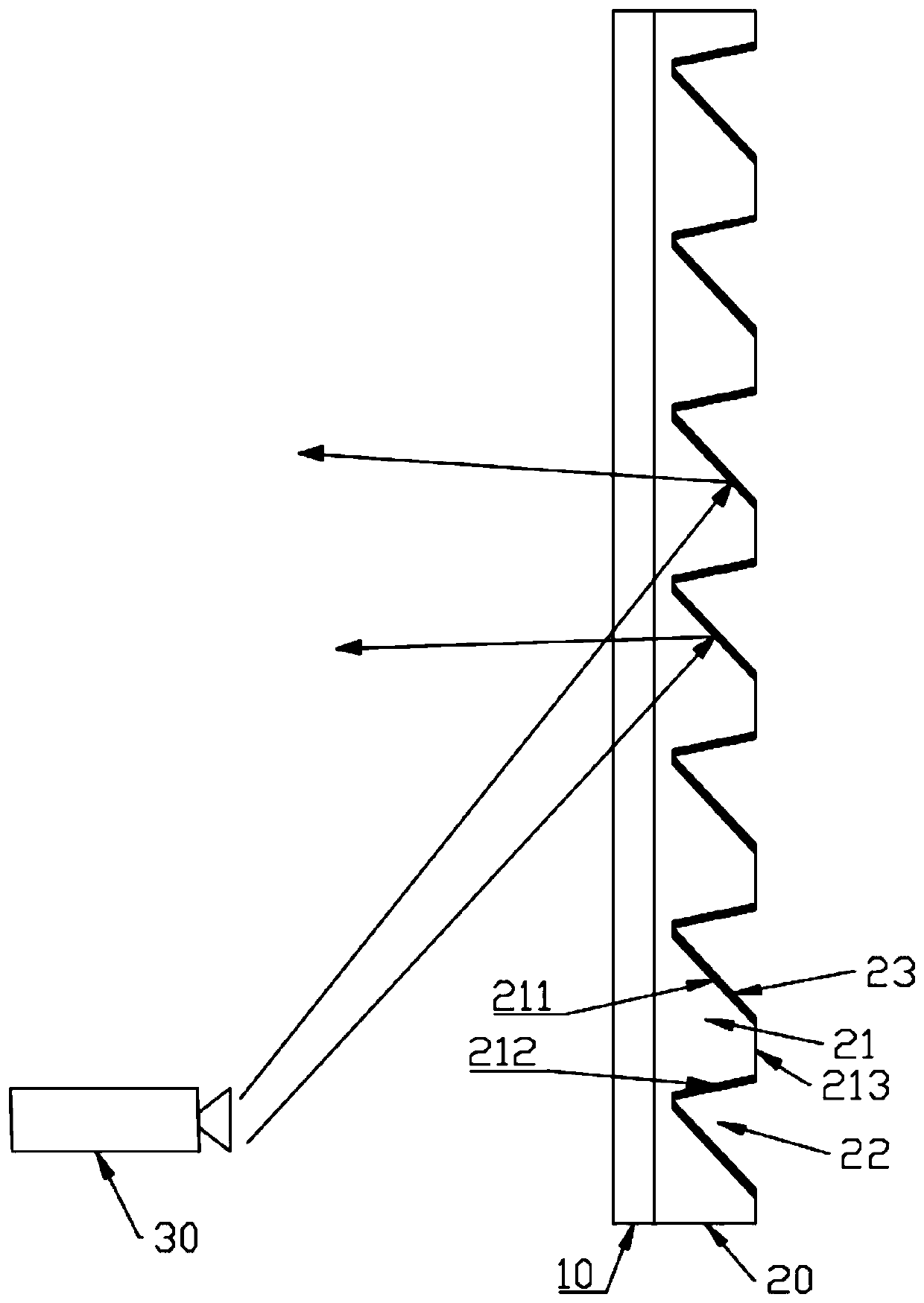

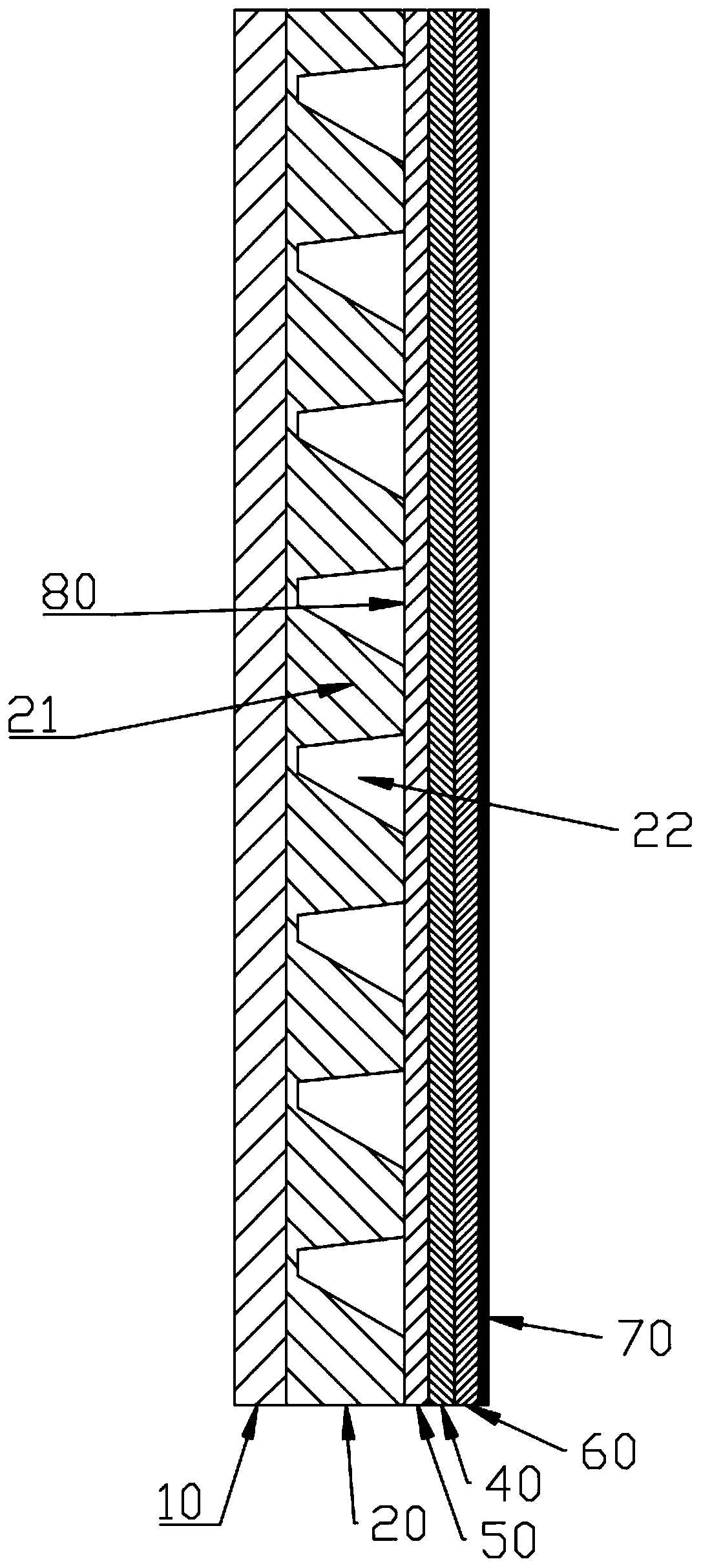

[0023] like Figure 1 to Figure 6 As shown, the transparent projection film of the present invention includes a substrate layer 10 and a lens layer 20 , further, it may further include a transparent film layer 40 and a release film 70 .

[0024] like Figure 1 ~ Figure 3 As shown, the substrate layer 10 is used to carry the lens layer 20 , which is transparent and made of transparent materials, such as PET, PP, PC, PVC, PMMA, glass and other transparent materials. In this embodiment, the substrate layer 10 is made of PET material.

[0025] like Figure 1 ~ Figure 3 As shown, the lens layer 20 is composited on the base material layer 10, and is used to act on projection light to achieve projection effects. The lens layer 20 includes a plurality of prism units 21 . The prism units 21 may be integrally formed or int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com