Permanent magnet synchronous motor finite time dynamic surface control method considering iron loss

A technology of dynamic surface control and permanent magnet synchronization, which is applied in motor control, motor generator control, AC motor control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

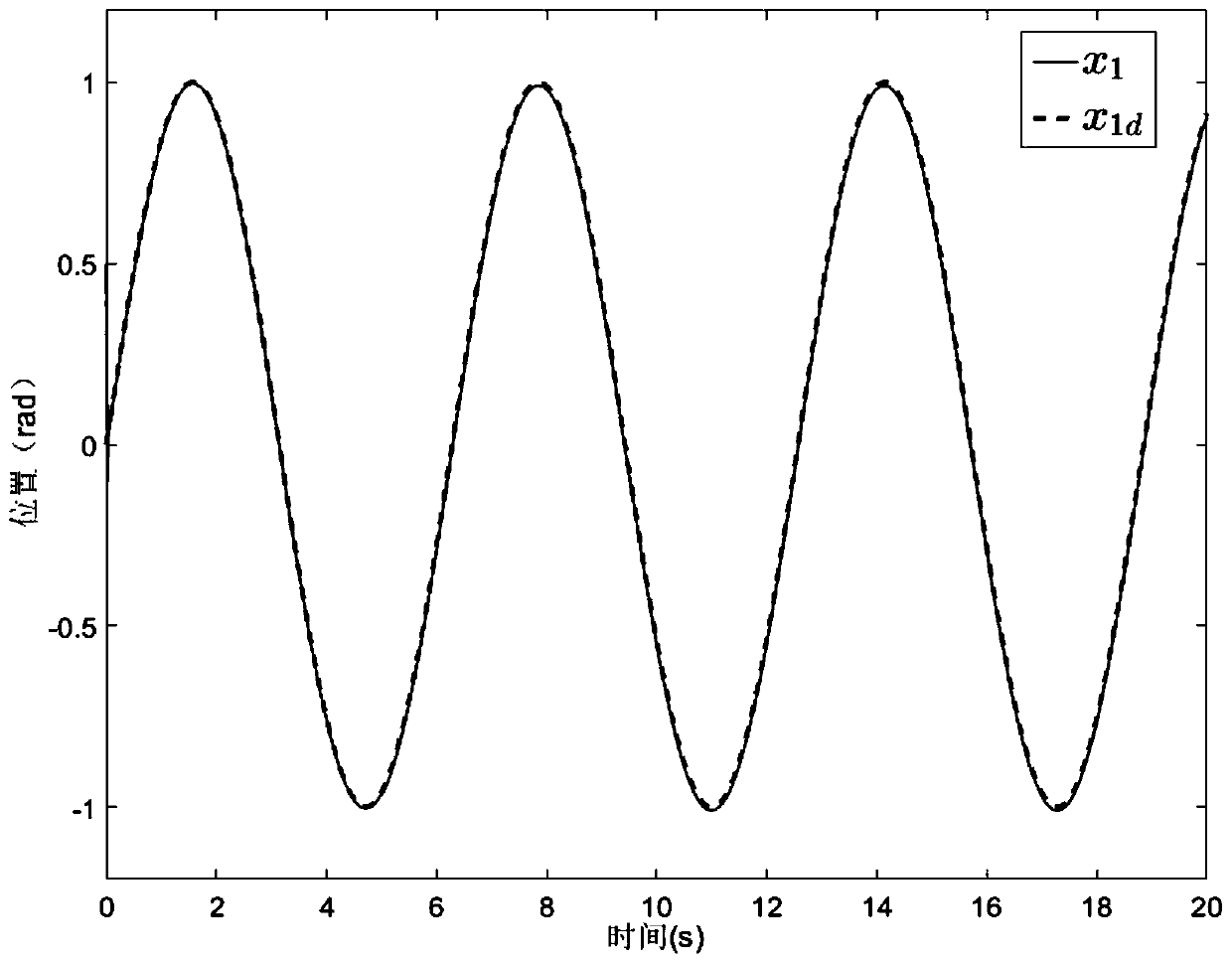

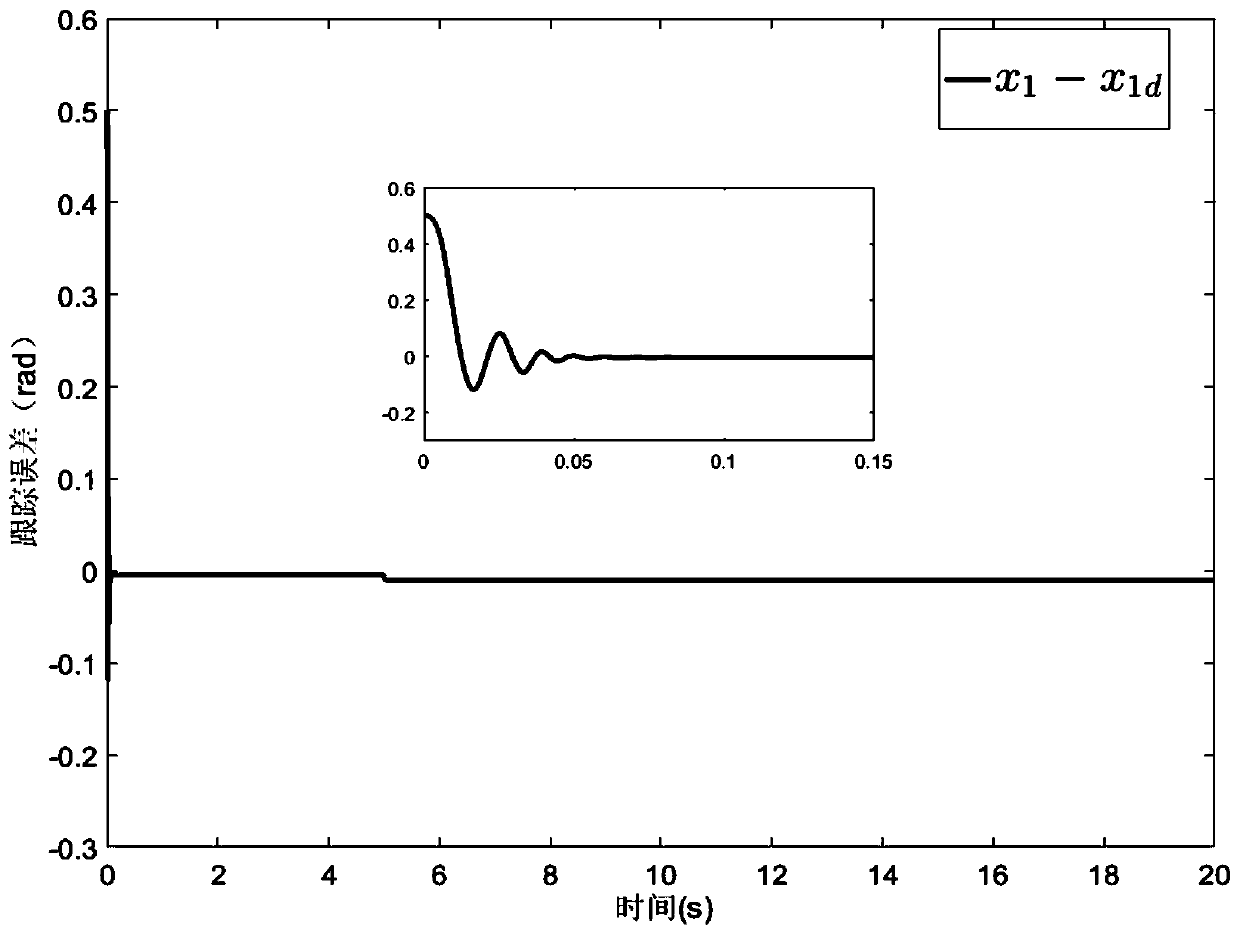

[0123] The basic idea of the present invention is: by combining the self-adaptive backstepping method and the dynamic surface technology and applying it to the position tracking control of the permanent magnet synchronous motor, to solve the uncertain parameters and external load changes in the permanent magnet synchronous motor drive system problem and the "computational complexity" problem in the traditional backstepping method; the adverse effects of iron loss and input saturation on the permanent magnet synchronous motor are considered; the limited time control technology is introduced to make the tracking error within a limited time Converging to a very small field of the origin, the control method of the present invention has higher engineering practice value and obtains ideal tracking effect.

[0124] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

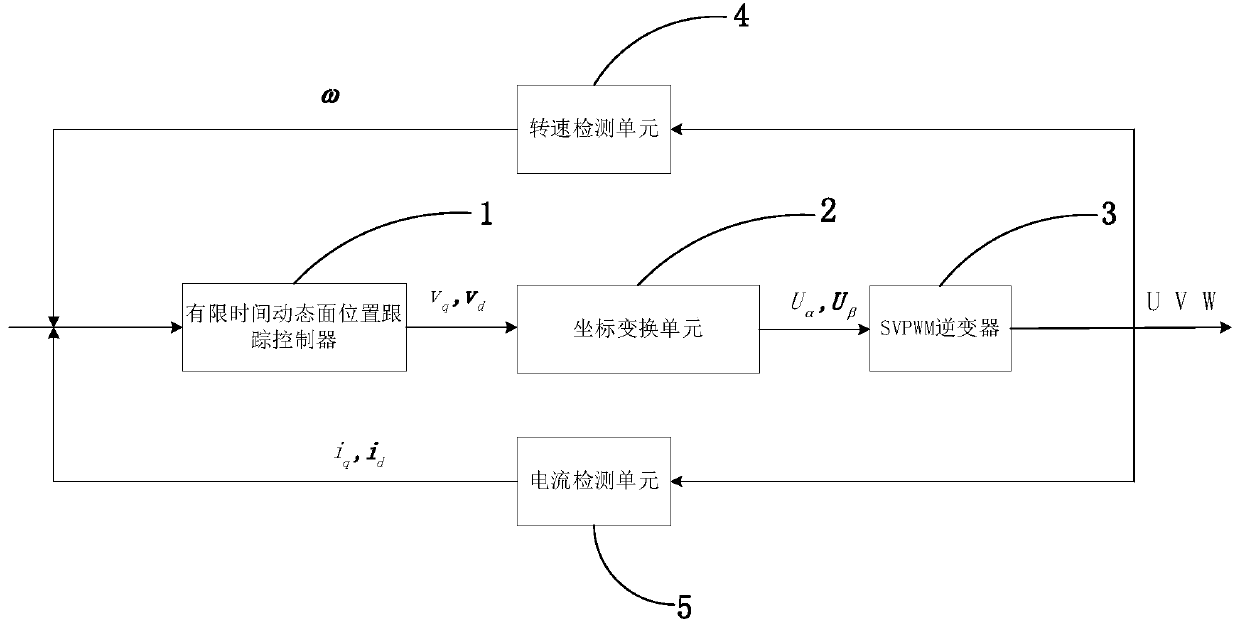

[0125] combine figure 1 As shown, a finit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com